Nitrogen-filled type pressure vessel for sealed glass lining equipment

A pressure vessel and glass-lined technology, applied in the field of pressure vessels for nitrogen-filled airtight glass-lined equipment, can solve the problems of single function, simple design structure, and inability to discharge excess gas, so as to achieve improved exhaust capacity, multiple functions, and increased The effect of practicality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

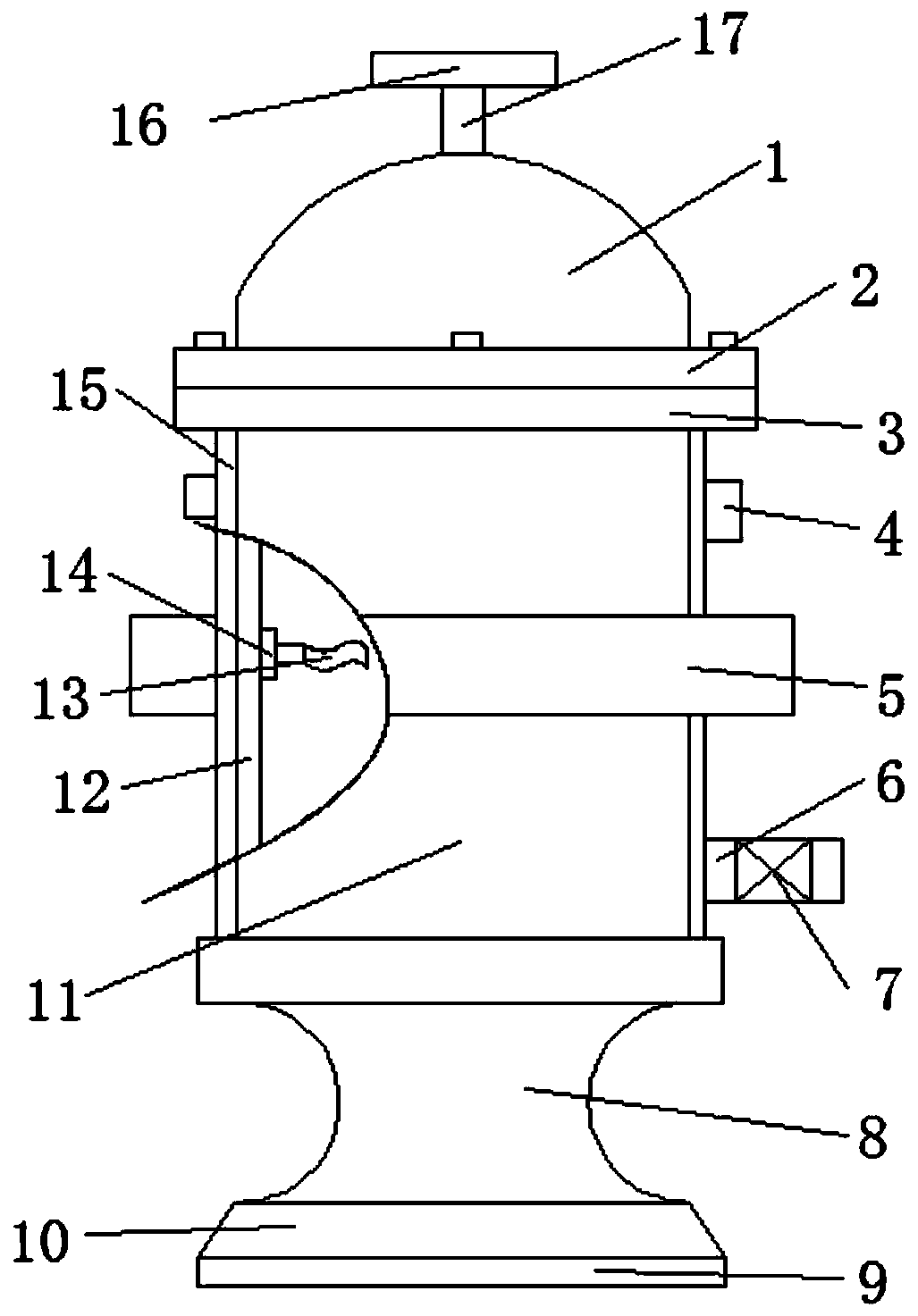

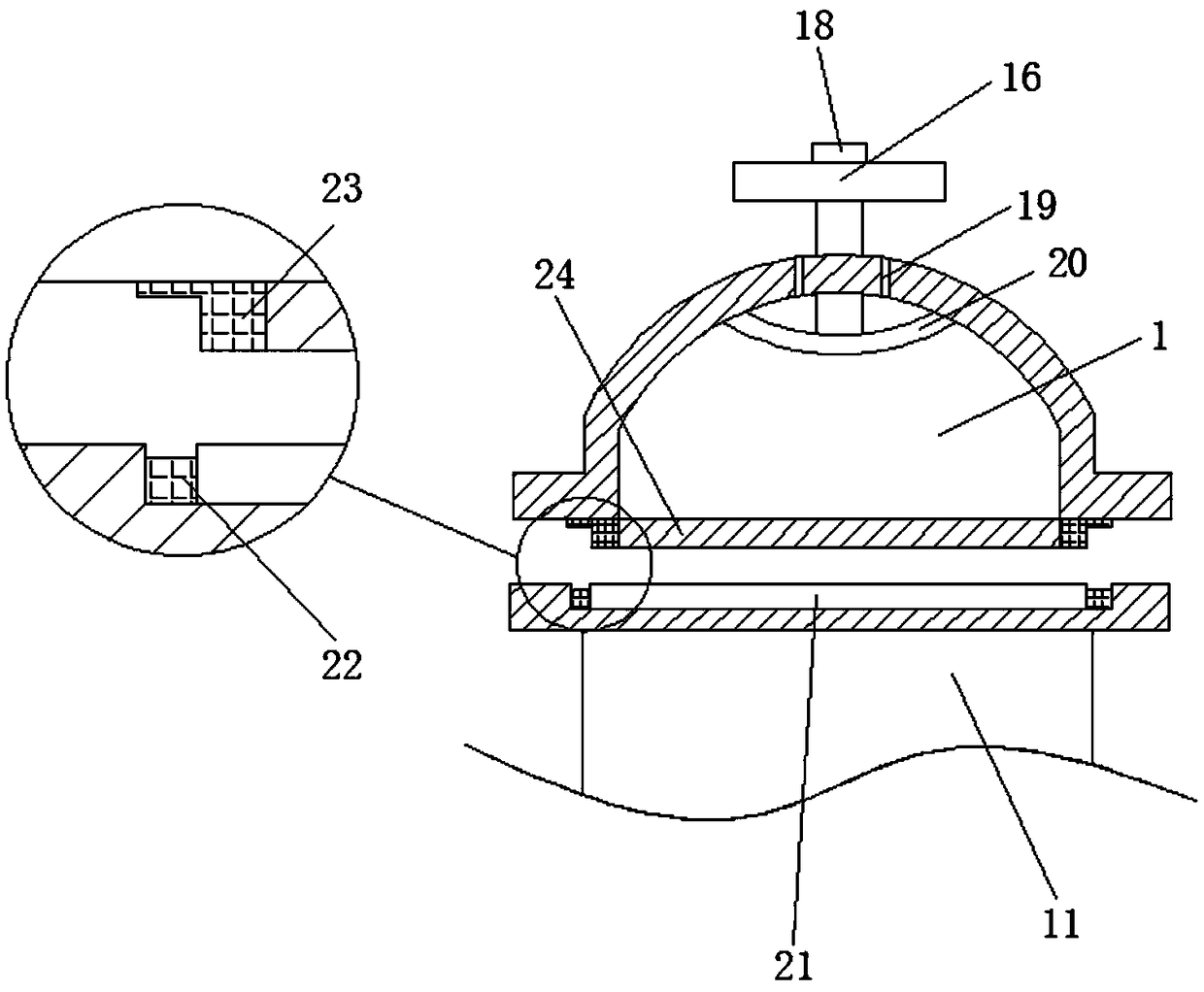

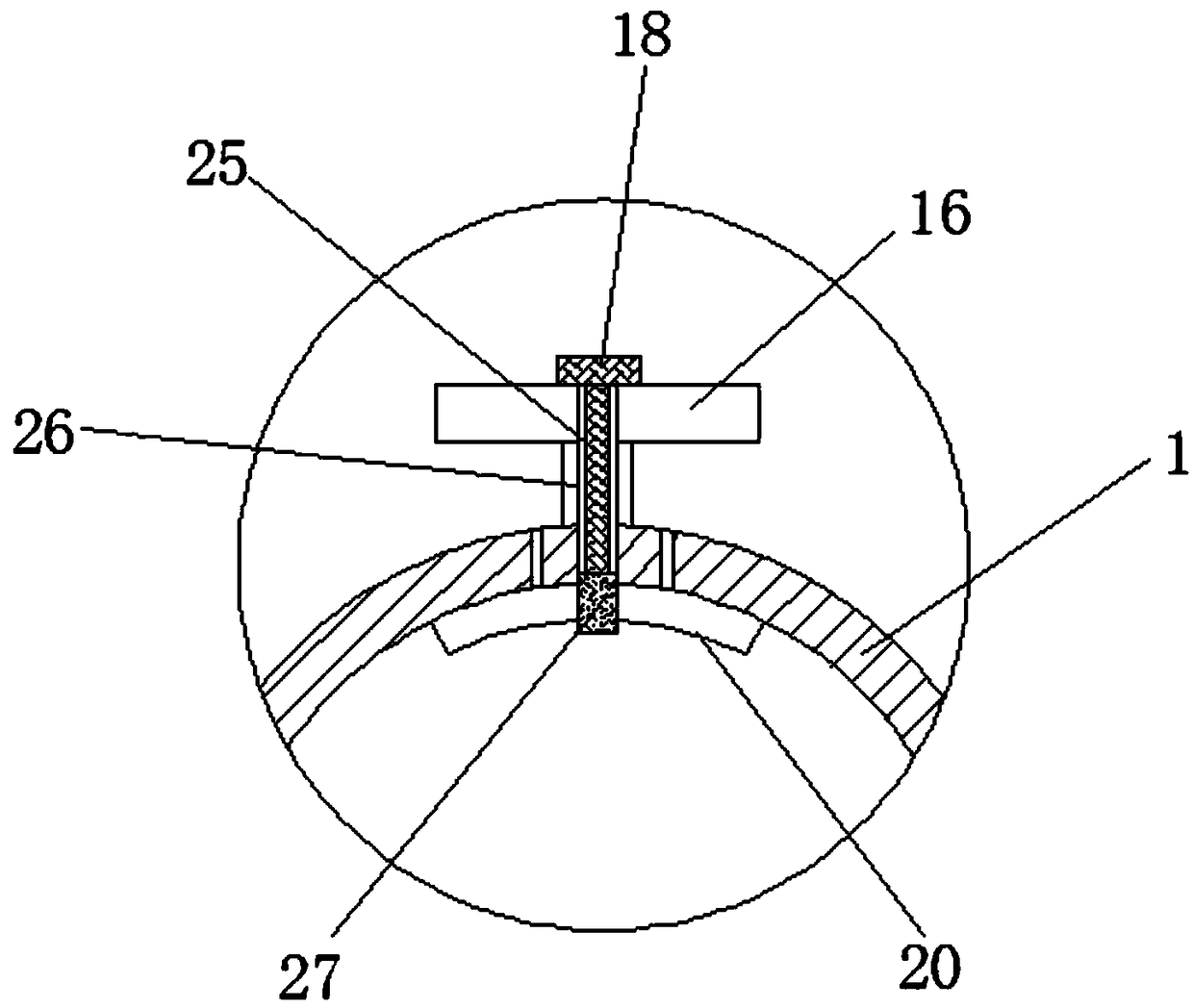

[0028] refer to Figure 1-5 , a pressure vessel for nitrogen-filled airtight glass-lined equipment, comprising an upper cover 1, a container cylinder 11 and a shock-absorbing base 8, the upper cover 1 is a hemispherical cover body, which increases the accommodation volume of the device, and the upper outer wall of the upper cover 1 is opened There is a threaded hole, and the internal thread of the threaded hole is connected with a threaded connecting rod 17 with matching specifications. The outer wall of the top of the threaded connecting rod 17 is welded with a rotating disc 16. Adapted annular suction cup 20, the top inner wall of the upper cover 1 is provided with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com