Automatic excessive gas diffusing system

A kind of gas and automatic technology, which is applied in the field of gas transmission and storage engineering, can solve the problems of personnel poisoning, environmental pollution, gas tank reduction, etc., and achieve the effect of protecting safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

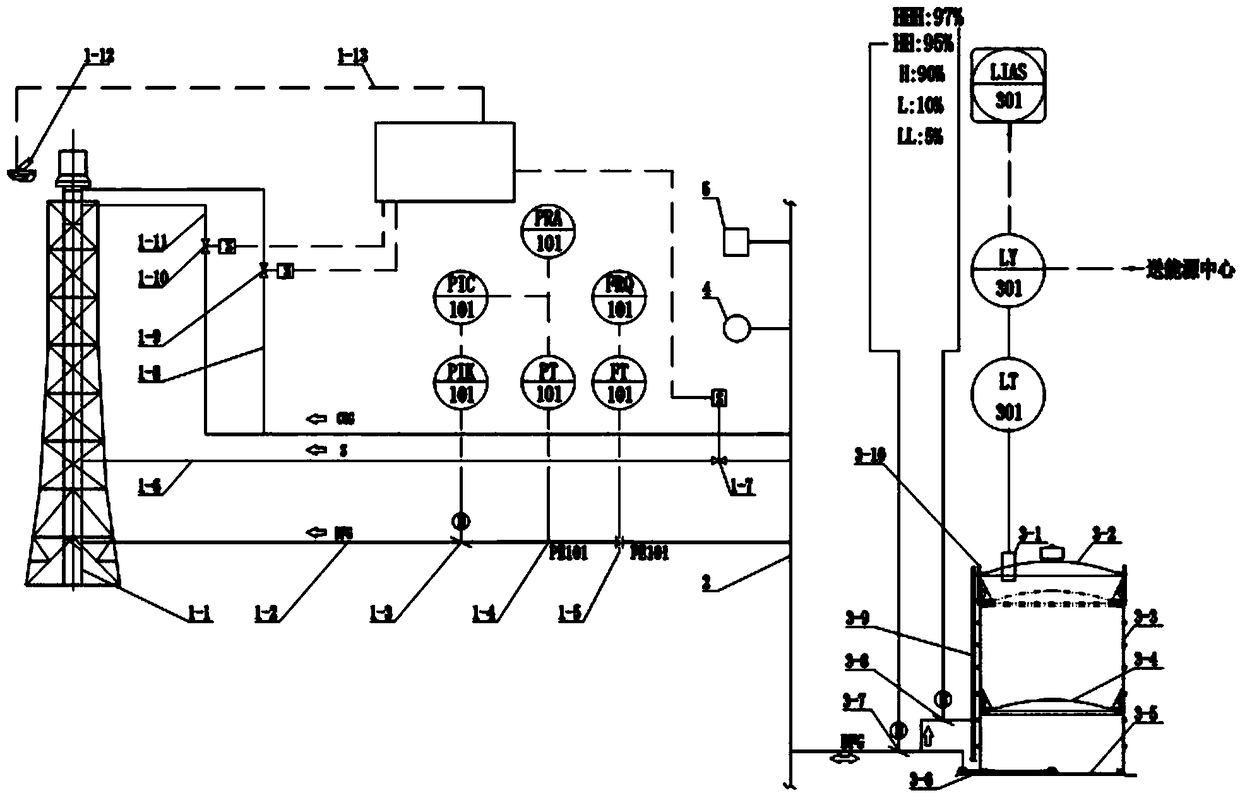

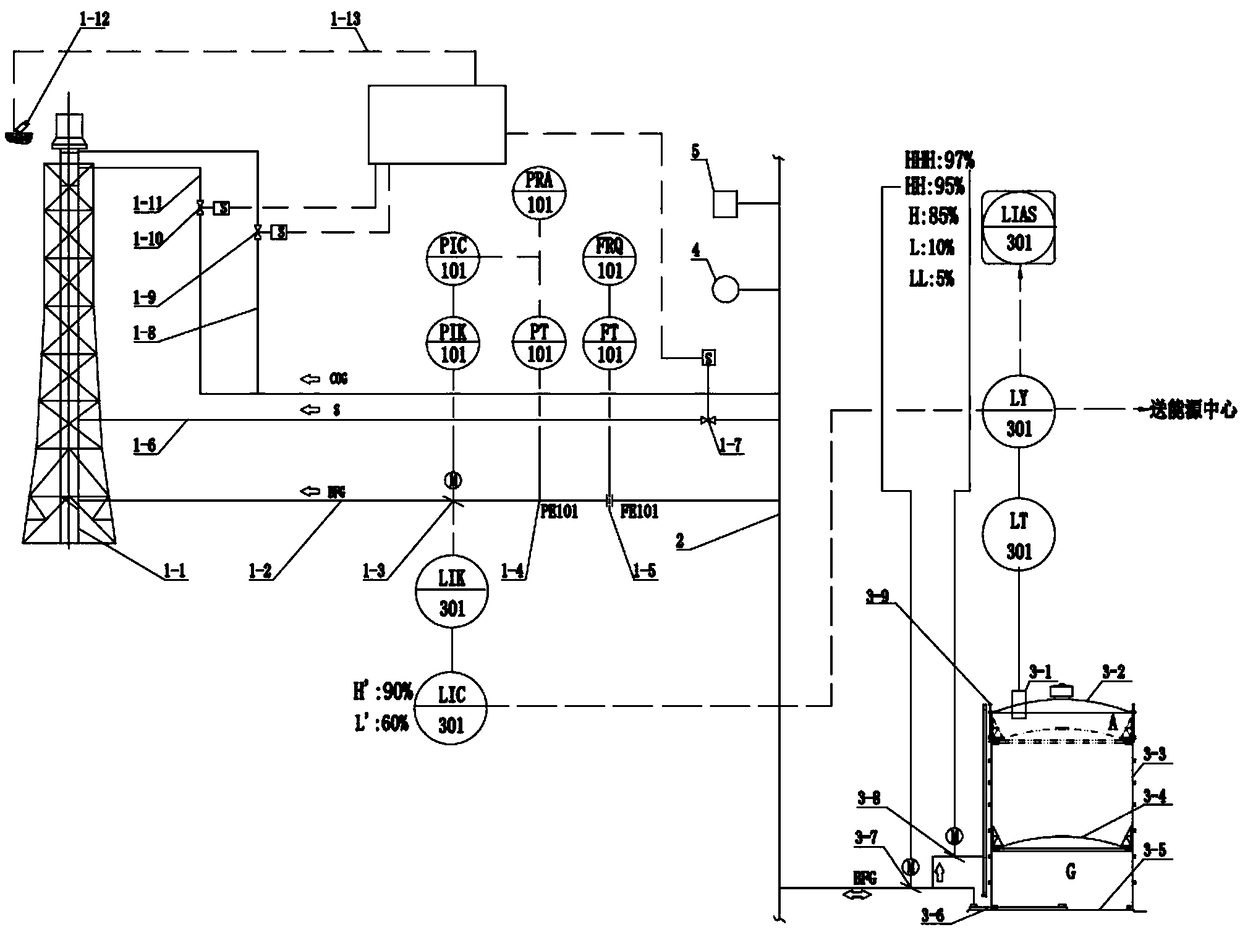

[0018] In the following, the preferred embodiment of the present invention will be described in detail by taking the blast furnace gas automatic release system (including the blast furnace gas holder system) in the blast furnace gas pipeline network of the iron and steel complex in conjunction with the accompanying drawings as an example.

[0019] The reference signs in the manual are: excess blast furnace gas automatic release system 1, whole plant pipe network 2, blast furnace gas cabinet system 3, gas source plant 4, blast furnace gas user 5, blast furnace combustion release riser and tower 1-1, release system Blast furnace gas main pipe 1-2, blast furnace gas regulating valve 1-3, blast furnace gas pressure detection device 1-4, flow meter 1-5, steam pipeline 1-6, steam solenoid valve 1-7, coke oven gas pipeline for co-firing 1-8. Coke oven gas solenoid valve for accompanying combustion 1-9, coke oven gas solenoid valve for ignition 1-10, coke oven gas pipeline for ignition...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com