Catalyst calcining box

A catalyst and calcination technology, which is applied in the direction of catalyst activation/preparation, physical/chemical process catalysts, chemical instruments and methods, etc. It can solve the problems that the box atmosphere cannot be adjusted and controlled, the equipment structure is complicated, and the temperature distribution is uneven. Uniform heating temperature distribution, slowing down exothermic reaction, slowing down and reducing the effect of thermal shock

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

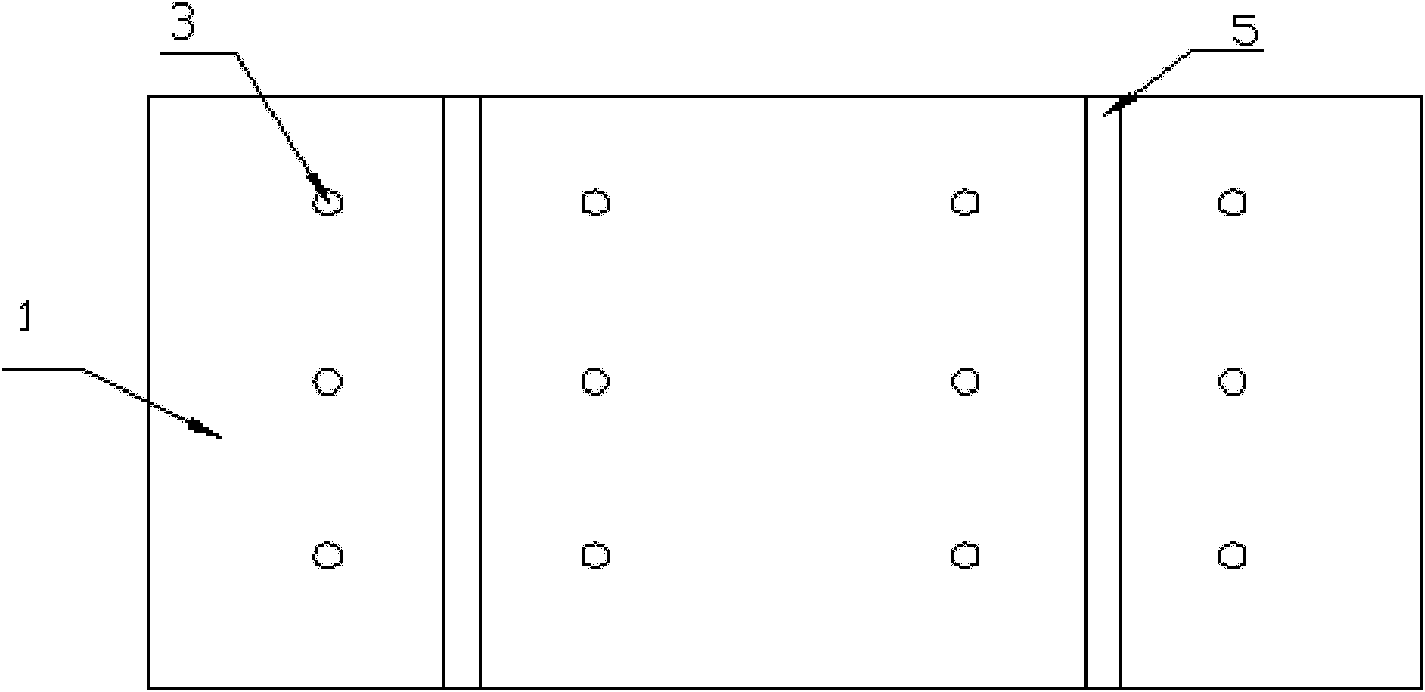

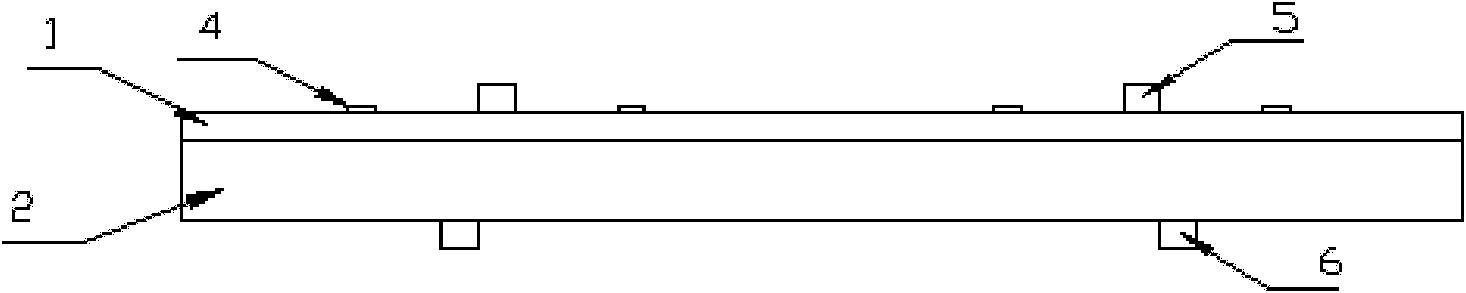

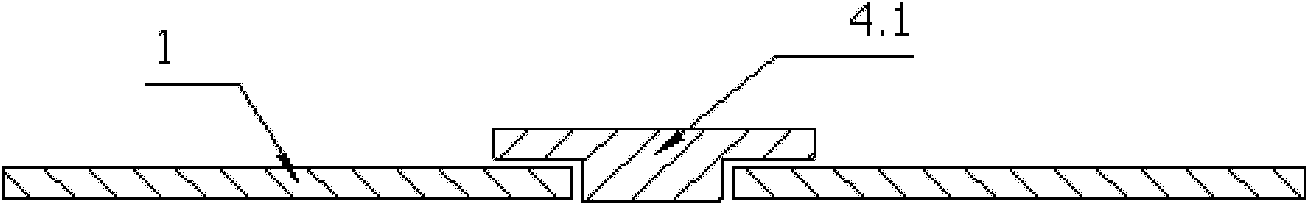

[0031] Such as figure 1 As shown, 12 vent holes are evenly arranged on the cover of the calcining box, and the diameter of the vent holes is 20mm; all 12 vent holes are covered with air hole caps, and the air hole caps are made of image 3 The shape shown in 4.1; the calcination box is evenly filled with 18×18-hole honeycomb SCR denitration catalyst dry monomer, and the calcination is carried out according to the existing calcination procedure.

Embodiment 2

[0033] On the cover of the calcining box, 4 vent holes are evenly arranged, and the vent holes are all covered with caps. Other conditions are the same as in Example 1, and calcining is carried out according to the existing calcining procedure.

Embodiment 3

[0035] The air hole cap adopts Figure 4 For the shape shown in 4.2, other conditions are the same as in Example 1, and the calcination is carried out according to the existing calcination procedure.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com