Method for molding resin matrix composite material by zero-adhesive-discharge vacuum assisted resin infusion (VARI)

A resin infiltration, vacuum-assisted technology, applied in the field of liquid molding of resin-based composite materials, can solve the problems of high glue content, failure of protective resin function, and inability to protect, so as to improve the fiber volume content and thickness uniformity, and reduce resin penetration. The effect of time and precise control of resin dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

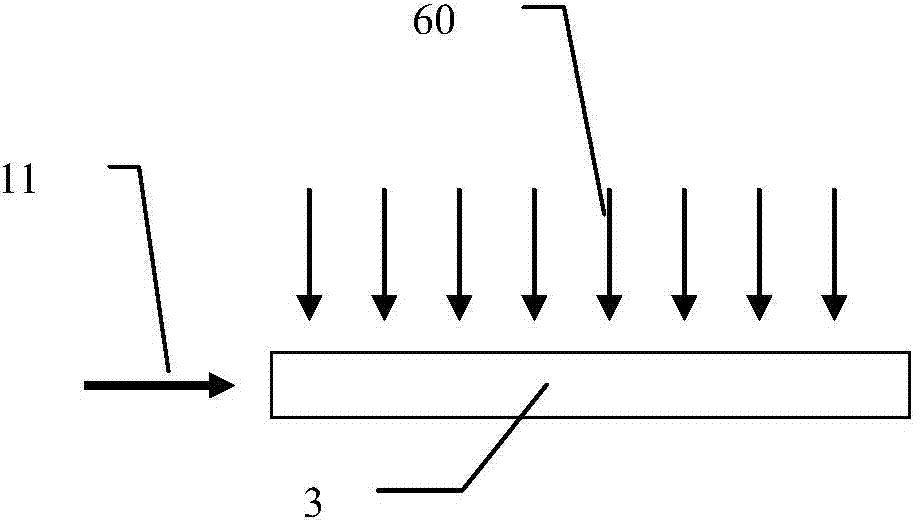

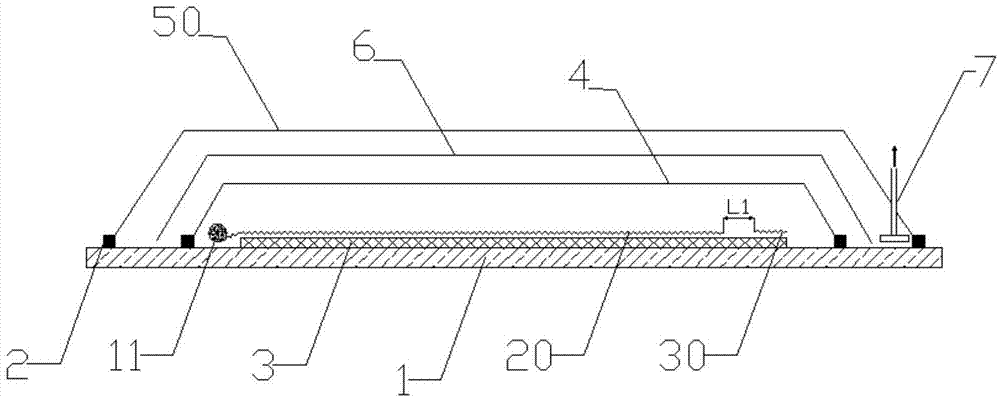

[0057] The fiber preform 3 is a composite laminate structure, and the material system is U7192 / BA9912; the U7192 cord fabric is a unidirectional fiber fabric woven with T700 grade carbon fiber with a specification of 12K produced by Toray Corporation of Japan, and the BA9912 resin is AVIC composite Materials Co., Ltd. develops a special resin for the liquid molding process. The injection viscosity of the BA9912 resin is set to 250cp. The external dimensions of the part are: 2000mm×1000mm×3.8mm (length×width×thickness). The design requires that the thickness tolerance range of the part is ± 8%, system layout such as image 3 .

[0058] 1. Place the fiber-reinforced preform 3 on the template 1 that has been pre-applied with a release agent;

[0059] 2. Place an insulating material on the fiber reinforced preform 3, place the glue feeding channel 11 on the template and cling to one side of the fiber reinforced preform 3;

[0060] 3. Place the glue-feeding guide net 20 on the si...

Embodiment 2

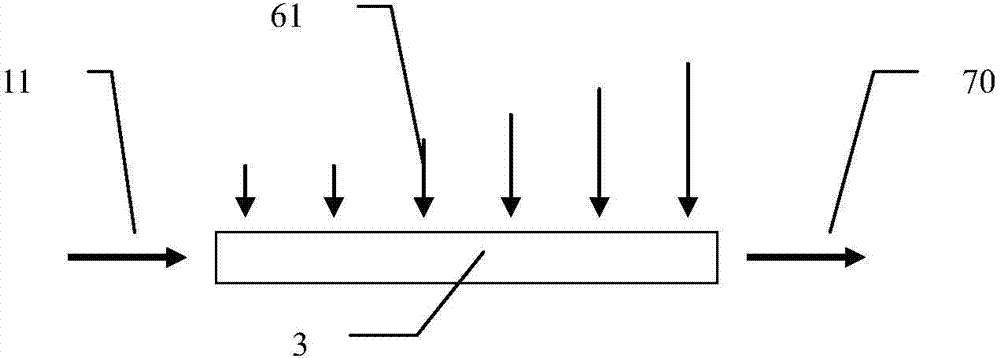

[0072] Carry out as described in Example 1, the difference between Example 2 and Example 1 is that the material system in Example 2 is U3160 / BA9914, wherein the U3160 woven fabric is T300 grade unidirectional with a specification of 3K produced by Shandong Weihai Development Company Carbon fiber fabric, BA9914 resin is a special resin developed by AVIC Composite Materials Co., Ltd. for the liquid molding process. The injection viscosity of BA9914 is set to 90cp, and the overall size of the part is 2000mm×1000mm×2.8mm (length×width×thickness), system layout Such as Figure 4 As shown, the formwork, edge sealing putty and vacuum bag used in embodiment 2 are the same as in embodiment 1.

[0073] 1. Place the fiber-reinforced preform 3 on the template 1 that has been pre-applied with a release agent;

[0074] 2. Place an insulating material on the fiber reinforced preform 3, place the glue feeding channel 11 on the template and cling to one side of the fiber reinforced preform 3;...

Embodiment 3

[0088] Carry out as described in Example 1, the only difference between Example 3 and Example 1 is that the fiber preform 3 in Example 3 is a composite material with a "J"-shaped reinforced panel structure, and the material system is G0827 / BA9912 ; Among them, the G0827 woven fabric is the T300 carbon fiber unidirectional fabric with a specification of 3K produced by HEXCEL.

[0089] The external dimensions of the part are 1500mm×1200mm (length×width), and the thickness of the skin is 4.65mm. There are three "J" shaped ribs longitudinally on the inner side of the skin, which are ribs 15, 16 and 17 respectively. The thickness of the reinforcing rib is 3.10mm, the length is 1500mm, the height is 30mm, the width of the bottom is 50mm, and the width of the top is 25mm. The design requires that the thickness tolerance range of parts is ±8%, and the system layout is as follows Figure 5 As shown, the template, sealing putty and vacuum bag used in Example 3 are the same as in Examp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com