A method for self-optimization of air-fuel ratio of blast furnace hot blast stove

A hot blast stove, air-fuel ratio technology, applied in the direction of combustion method, blast furnace, blast furnace details, etc., can solve the problems of unreasonable air-fuel ratio, low operating efficiency of hot blast stove, etc., achieve full energy utilization, improve combustion control level and combustion efficiency, The effect of strong heat storage capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

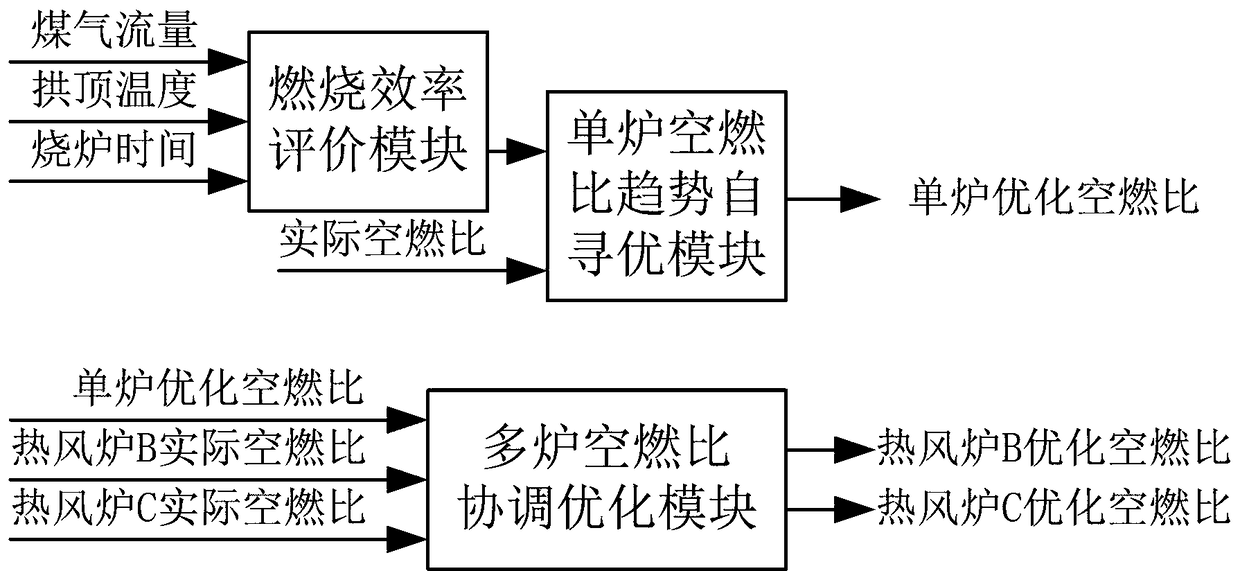

[0018] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

[0019] Combustion efficiency evaluation module of hot blast stove

[0020] At the time of firing T1, keep the air-fuel ratio constant, take T as the cycle, and continue for n cycles. The influence of the gas flow increment m1 on the vault temperature within n*T time is recorded as f(m1, T1), and the vault The average temperature is recorded as GT1. After the gas flow rate is changed, N sets of data f(m2, T2), f(m3, T3), ..., f(mN, TN) and GT2, GT3, ..., GTN are obtained, using multiple linear Regression analysis to obtain the influence of gas flow change on vault temperature F(N)= f(m1,T1)+ f(m2,T2)+...+f(mN,TN), the hot blast stove combustion efficiency evaluation module outputs hot air Furnace combustion efficiency evaluation value XLPJ=GTN-GT1-F(N), where T ranges from 6 to 10 seconds, n ranges from 10 to 30, and N ranges from 5 to 10.

[0021] S...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com