Composite phase change heat storage solar water heater without water tank

A solar water heater and composite phase change technology, applied in the field of solar heat utilization, can solve problems such as low efficiency of solar water heaters, hard scaling on the inner wall of heat collecting tubes, and decline in heat collection performance of heat collectors, and achieve good heat storage capacity and safety Good, beautiful appearance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with accompanying drawing.

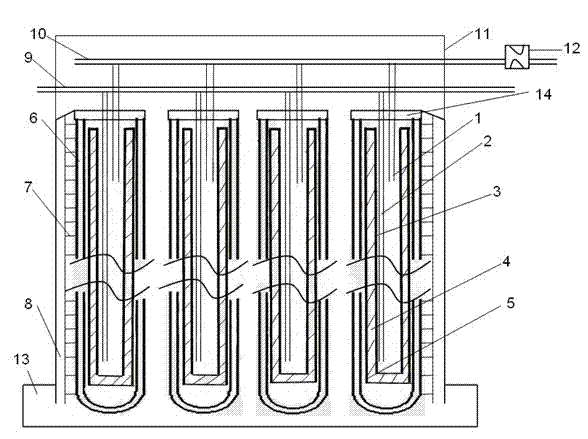

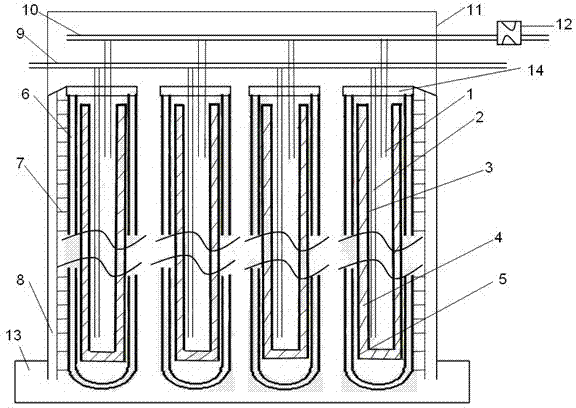

[0021] Such as figure 1 As shown, the tankless composite phase change heat storage solar water heater of the present invention includes: cover pipe 7, support 8, total cold water inlet pipe 9, total hot water outlet pipe 10, polyurethane insulation layer 11, solar energy companion 12, tailstock 13 and several vacuum heat collecting units. The bracket 8 is fixedly connected with the tailstock 13, and each vacuum heat collecting unit is placed on the tailstock 13 and fixed by the bracket 8, and the cover tube 7 is covered outside the bracket 8 to protect the vacuum heat collecting unit. Each vacuum heat collection unit includes an inner stainless steel tube 3 , a composite phase change heat storage material 4 , an outer stainless steel tube 5 , a vacuum glass tube 6 and a sealing plug 14 . The inner stainless steel tube 3 and the outer stainless steel tube 5 form a stainles...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com