Microcapsule capable of improving heat storage properties and composition molded body thereof

A technology of microcapsules and moldings, applied in the field of microcapsules and their composition moldings, can solve the problems of ignoring phase change microcapsule research, decline, etc., and achieve the effect of improving heat storage capacity and improving heat storage performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

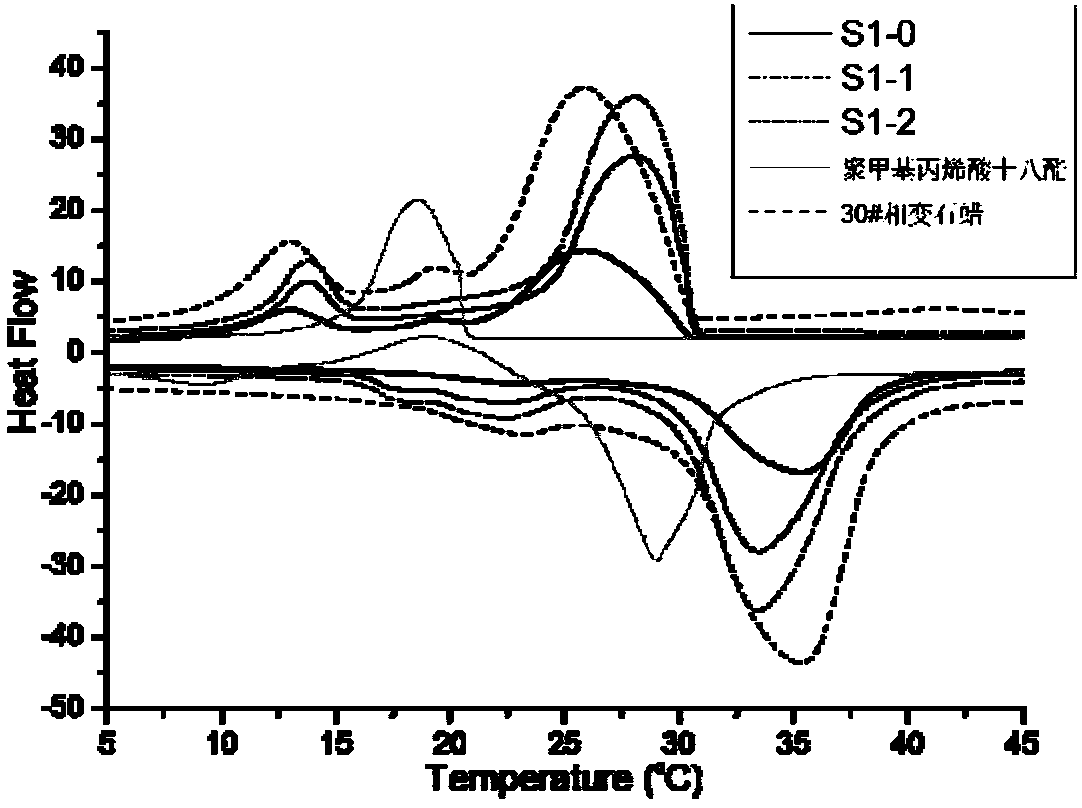

[0053] The first type of phase change microcapsules provided in this example to improve heat storage performance is numbered S1-1, its core material is industrial grade 30# phase change paraffin, and its shell material is polyoctadecyl methacrylate; the second type The number of phase-change microcapsules to improve heat storage performance is S1-2, its core material is industrial grade 30# phase-change paraffin, and its shell material is polymethyl methacrylate and polyoctadecyl methacrylate (two polymers The mass ratio is 1:1); compared with phase-change microcapsules (number S1-0), the core material is industrial grade 30# phase-change paraffin, and the shell material is polymethyl methacrylate. The difference in the preparation methods of the above three microcapsules is only in the type of shell material, and the other conditions are completely the same. The SEM photos of the three phase change microcapsules are attached figure 1 . In the figure, a is the traditional ph...

Embodiment 2

[0063] A phase-change microcapsule provided in this example to improve heat storage performance is numbered S2-1, its core material is industrial grade 30# phase-change paraffin, and its shell material is polyoctadecyl methacrylate; one of this example A comparative phase-change microcapsule (numbered S2-0), whose core material is industrial-grade 30# phase-change paraffin, and whose shell material is polymethyl methacrylate. The difference in the preparation methods of the above two microcapsules is only in the type of shell material, and the other conditions are completely the same.

[0064] In this example, microcapsules S1-1 and S1-0 described in Example 1 are used. After 4 kinds of microcapsules are tested by laser particle size analyzer, the particle size distribution curve is obtained as Figure 5 Shown; DSC curve see Figure 6 . The particle size analysis data and DSC data are summarized in Table 2.

[0065] Since the above-mentioned preparation methods of microcaps...

Embodiment 3

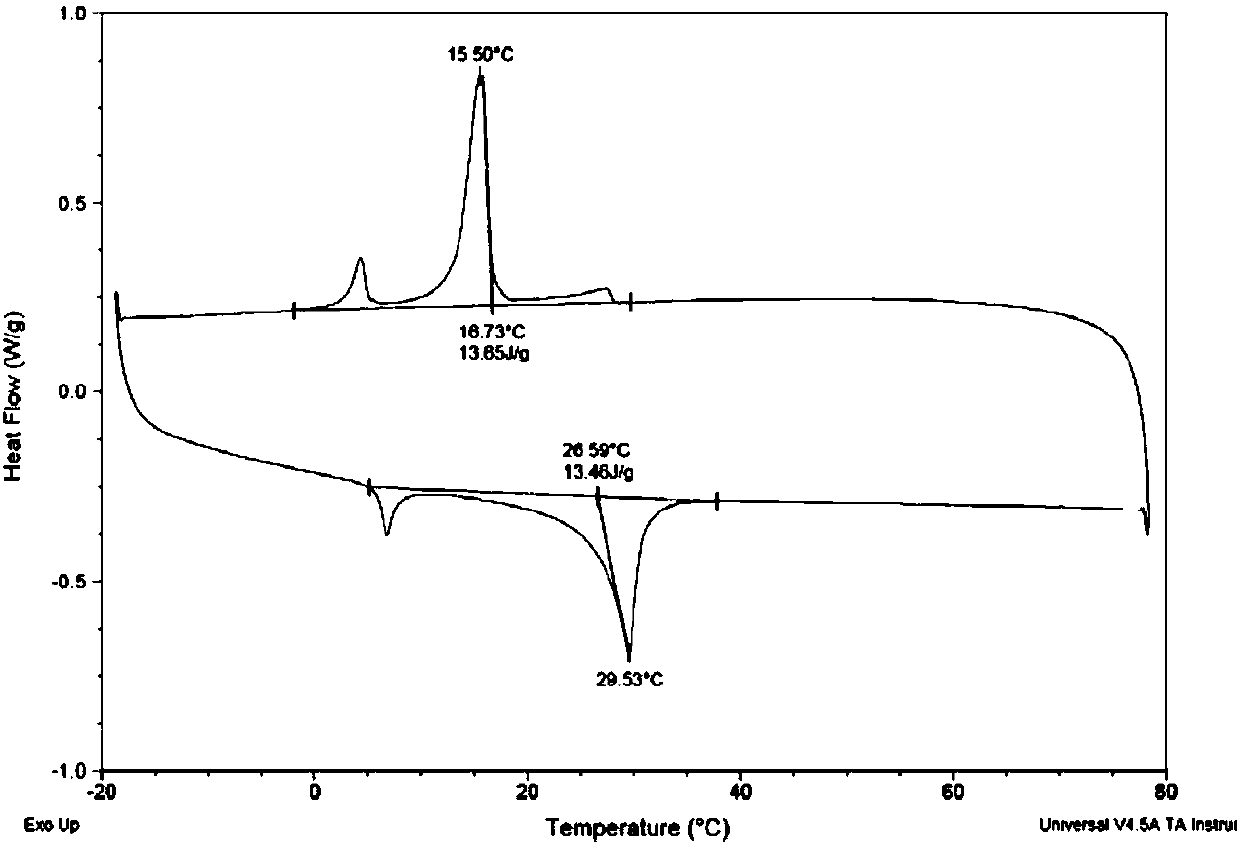

[0075] In this example, a phase-change microcapsule with improved heat storage performance is provided, the core material of which is a gallium-based metal alloy with a melting point of 29°C. The shell material is a block polymer with solid-solid phase transition, the soft segment is polyethylene glycol, the hard segment is polyurethane (MDI), and the phase transition temperature is 65°C.

[0076] In this example, the core material and the shell material have different phase transition temperatures, which can store heat at different temperatures, or adjust the temperature in sections.

[0077] The microcapsules obtained in this example are blended with polymers and used for foaming materials or mold making to obtain a molded microcapsule composition with improved heat storage performance according to the present invention.

[0078] This example product can be used in healthcare, electronics, storage and transportation, containers, and other products.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| phase transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com