Composite phase-change energy storage movable heat supply vehicle

A phase-change energy storage and composite technology, which is applied in the direction of motor vehicles, heat storage equipment, and object transport vehicles, can solve the problems of supercooling and phase separation, low thermal conductivity, and poor energy storage capacity, and achieve low cost, High energy storage density and stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

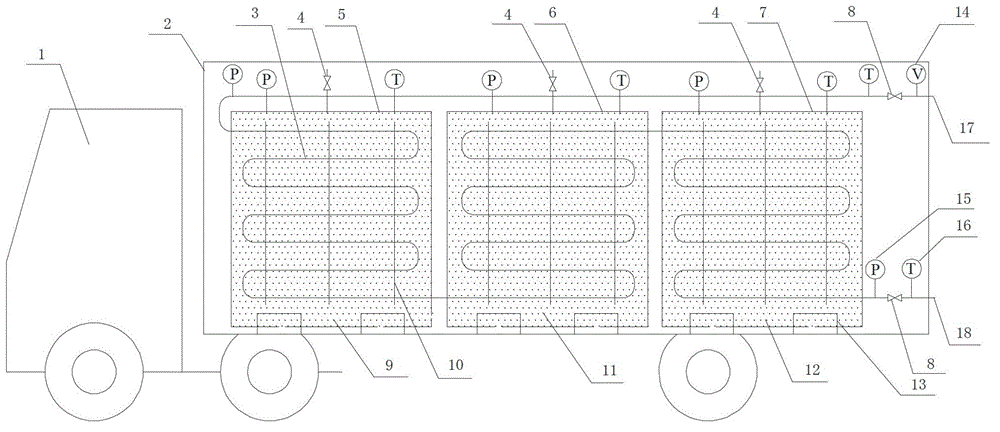

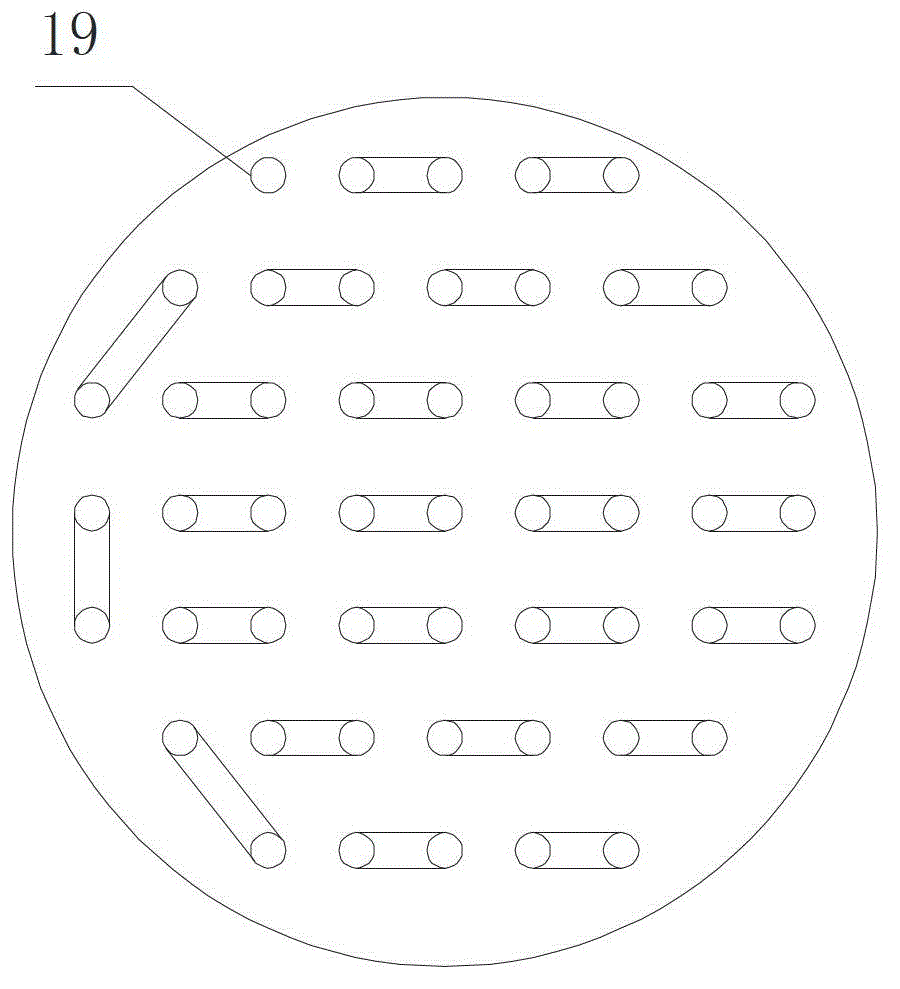

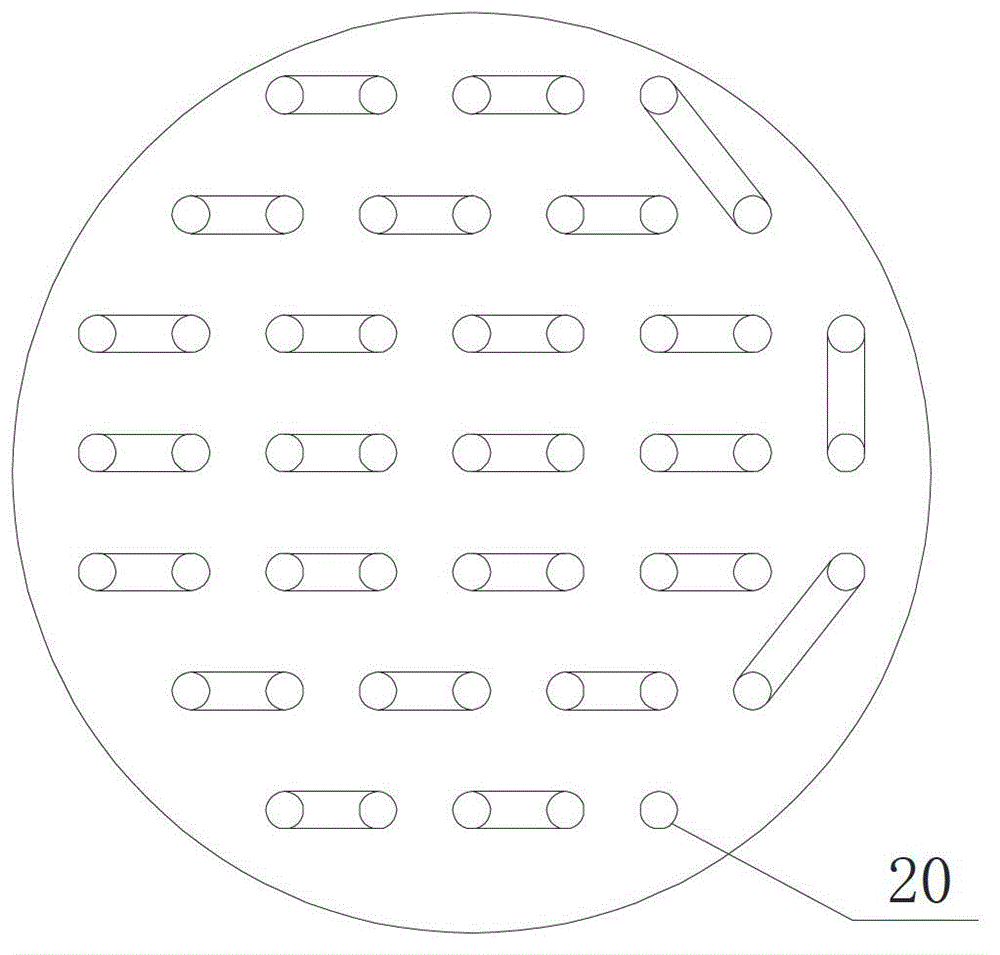

[0026] combine figure 1 , figure 2 , image 3 and Figure 4 , a composite phase-change energy storage mobile heating vehicle, comprising a truck body 1, the truck body includes an insulated compartment 2, and a high-temperature phase-change heat accumulator 5, a medium-temperature phase-change heat accumulator 6 and Low temperature phase change heat accumulator7. The above-mentioned high-temperature phase-change heat accumulator includes a casing 1, and a high-temperature phase-change material 9 and a heat exchanger 1 are arranged in the casing 1 . The medium-temperature phase-change heat accumulator includes a casing 2, and a medium-temperature phase-change material 11 and a heat exchanger 2 are arranged in the casing 2 . The low-temperature phase-change heat accumulator includes a casing three, and a low-temperature phase-change material 12 and a heat exchanger three are arranged in the casing three. The above-mentioned high-temperature phase-change heat accumulator, m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com