Three-riser pulsating tube bundle

A standpipe and pulsating flow technology, which is applied to fixed tubular conduit components, heat storage equipment, lighting and heating equipment, etc., can solve the problems of less heat exchange and insufficient heat exchange uniformity, and achieve improved heat exchange effect, The effect of increasing the vibration range and reducing the formation of scaling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

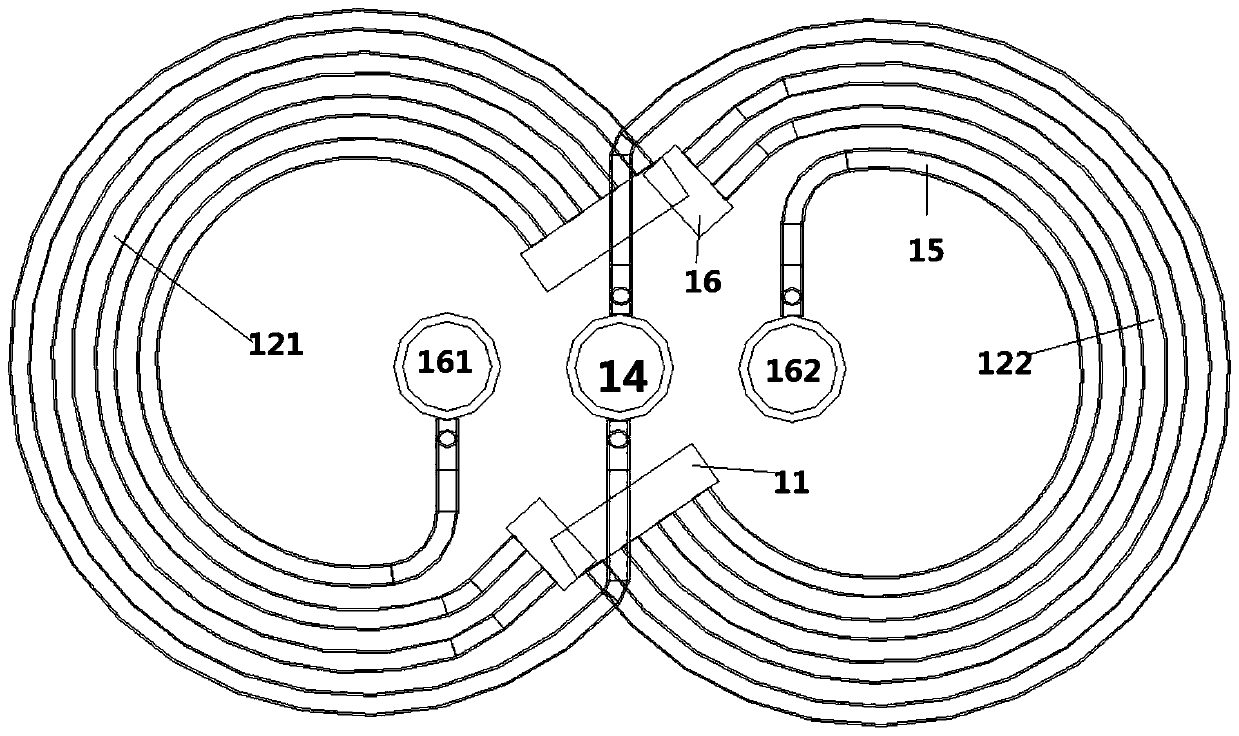

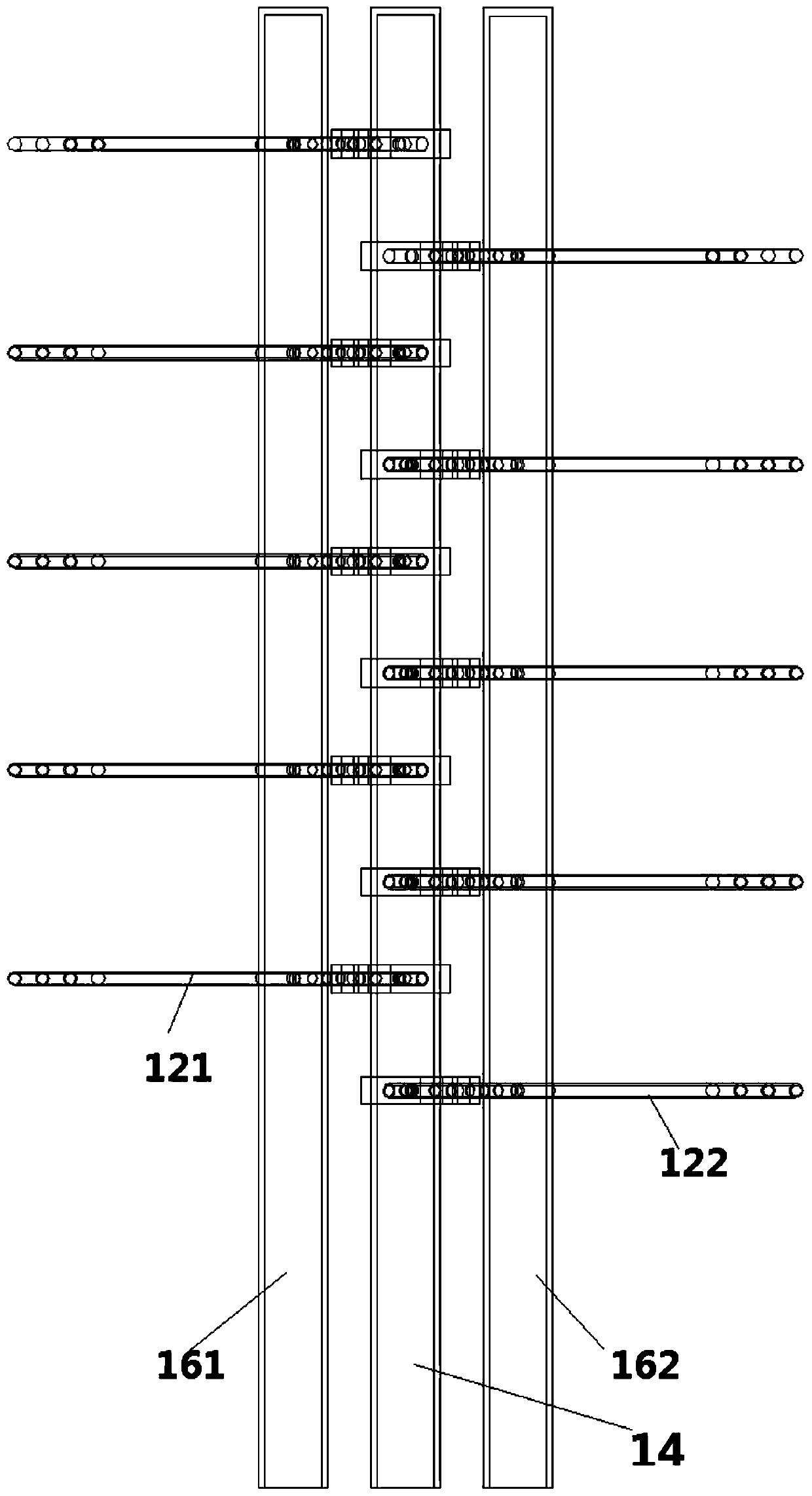

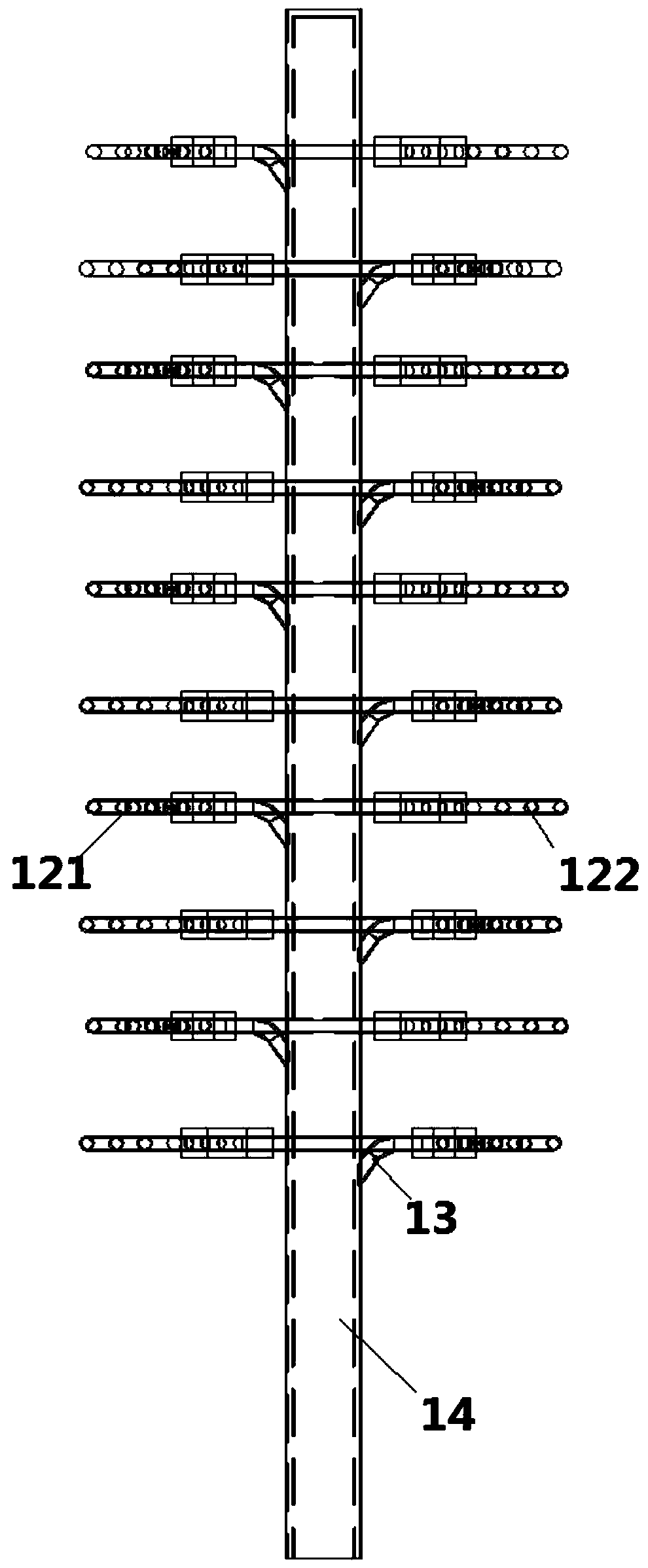

[0046] figure 1 A pulsating tube bundle with three risers is shown. Such as figure 1 The three standpipe pulsating tube bundles shown include the middle standpipe 14, the left standpipe 161, the right standpipe 162 and the coil pipe 12. Heat pipe 15, the end portion of adjacent heat exchange tube 15 communicates, makes a plurality of heat exchange tubes 15 form a series structure, and makes the end of heat exchange tube 15 form heat exchange tube free end ( figure 1 The position where the load-bearing block is set); the entrance of the middle standpipe 14 is connected with a pulsating flow generating device, which is used to generate a pulsating flow in the heat exchange tube 15, thereby further promoting the vibration of the elastic heat exchange tube bundle to enhance heat transfer and reduce Fouling.

[0047] The coil 12 includes a left coil 121 and a right coil 122, one side of the middle riser 14 is connected to the inlet of the left coil 121, the other side is connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com