A method for controlling heating of a loop heat pipe system according to temperature

A temperature control and loop heat pipe technology, applied in the field of heat pipes, can solve the problems of uneven heat absorption, occupancy, and low fluidity, and achieve the effects of increasing the vibration range, optimizing the best relationship, and improving heat exchange efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0037] In this article, if there is no special explanation, when it comes to formulas, " / " means division, and "×" and "*" mean multiplication.

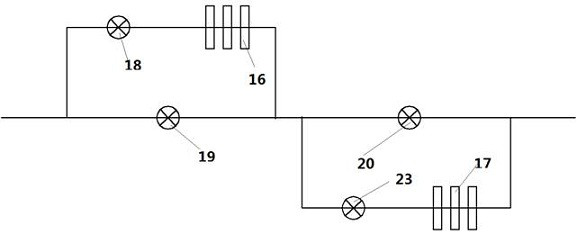

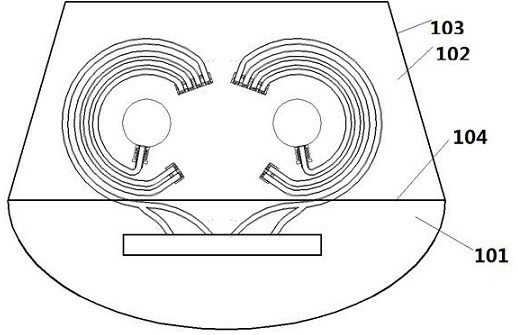

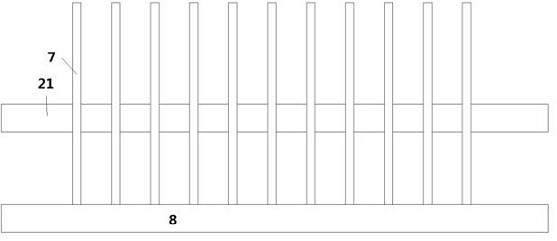

[0038] figure 1 A schematic diagram of the pipe structure of the waste heat utilization loop heat pipe of the present invention is disclosed. Such as figure 1 As shown, the flue gas pipeline 101 includes two bypass pipelines, a first bypass pipeline and a second bypass pipeline, wherein a first valve 18 and a heat pipe 16 are respectively arranged on the first bypass pipeline, and the first bypass pipeline The second valve 19 is set on the flue gas pipeline 101 corresponding to the pipeline. By setting the first valve 18 and the second valve 19, it is possible to control whether the flue gas passes through the heat pipe 16 for waste heat utilization. Wherein, the fourth valve 23 and the heat p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com