Accurate casting method for metal leakage type suction pouring titanium master alloy

A titanium-based alloy and vacuum suction casting technology, which is applied in the field of precision casting of titanium-based alloys, can solve problems such as alloy interstitial element pollution, heavy workload, and difficulty in obtaining shapes, and achieve easy mass production, fast cooling speed, and refined grain effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

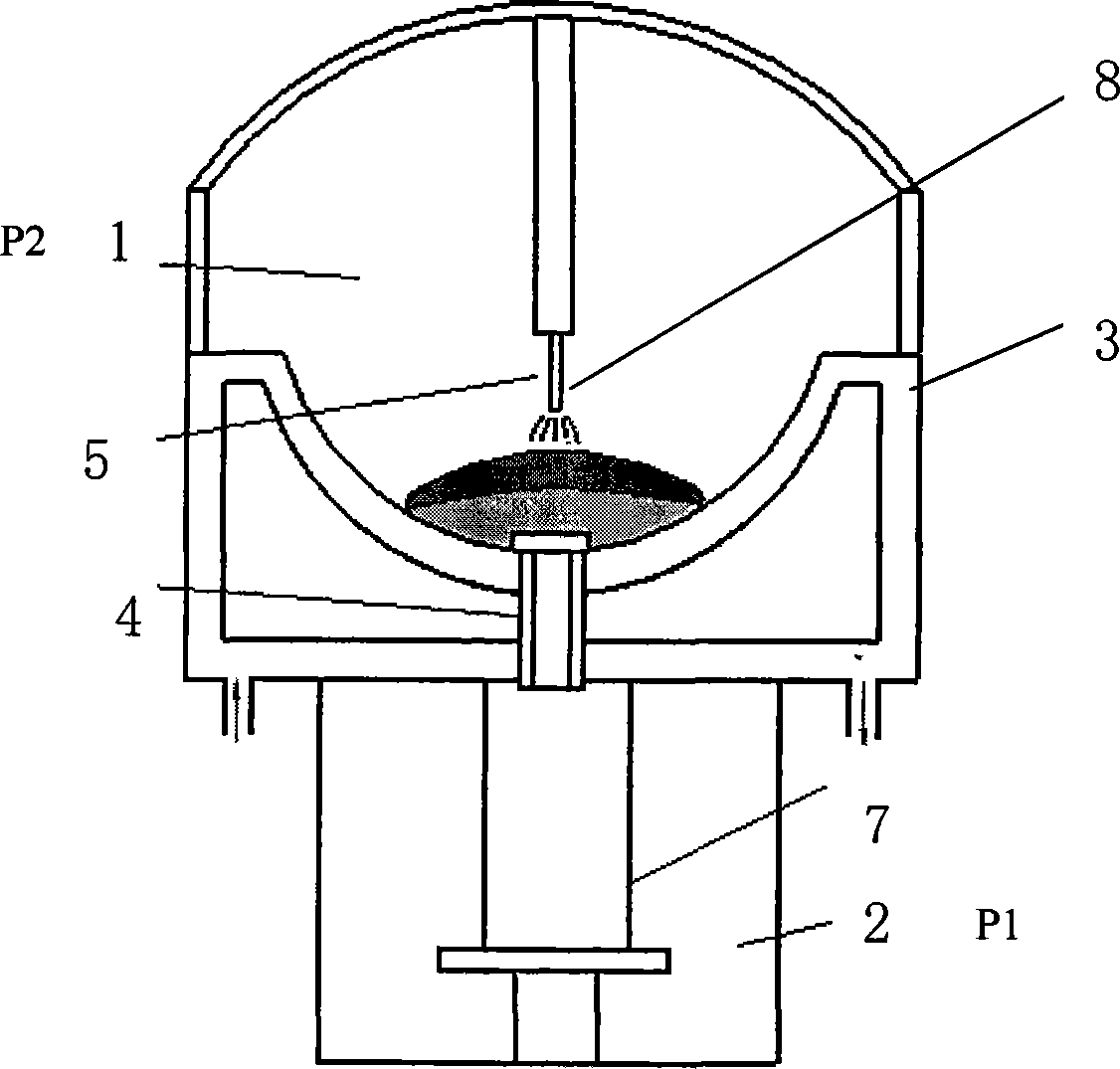

[0012] Specific implementation mode 1: The precision casting method of the metal mold bottom drain type vacuum suction casting titanium-based alloy described in this implementation mode is realized according to the following steps:

[0013] Step 1. Make a metal mold with a number of air holes in the cavity according to the needs. The air holes are distributed on the upper and lower positions of the metal mold. The air holes of the metal mold mold for making blades should be distributed on the upper and lower sides of the metal mold. middle and lower position;

[0014] Step 2, putting the titanium-based alloy prepared according to the pouring amount into a non-consumable electrode electric arc furnace for vacuum melting;

[0015] Step 3. Turn the titanium-based alloy ingot smelted in step 2 into the absorbable castable crucible in the non-consumable electrode electric arc furnace and then melt it, so that the liquid titanium-based alloy seals the graphite hole at the bottom of ...

specific Embodiment approach 2

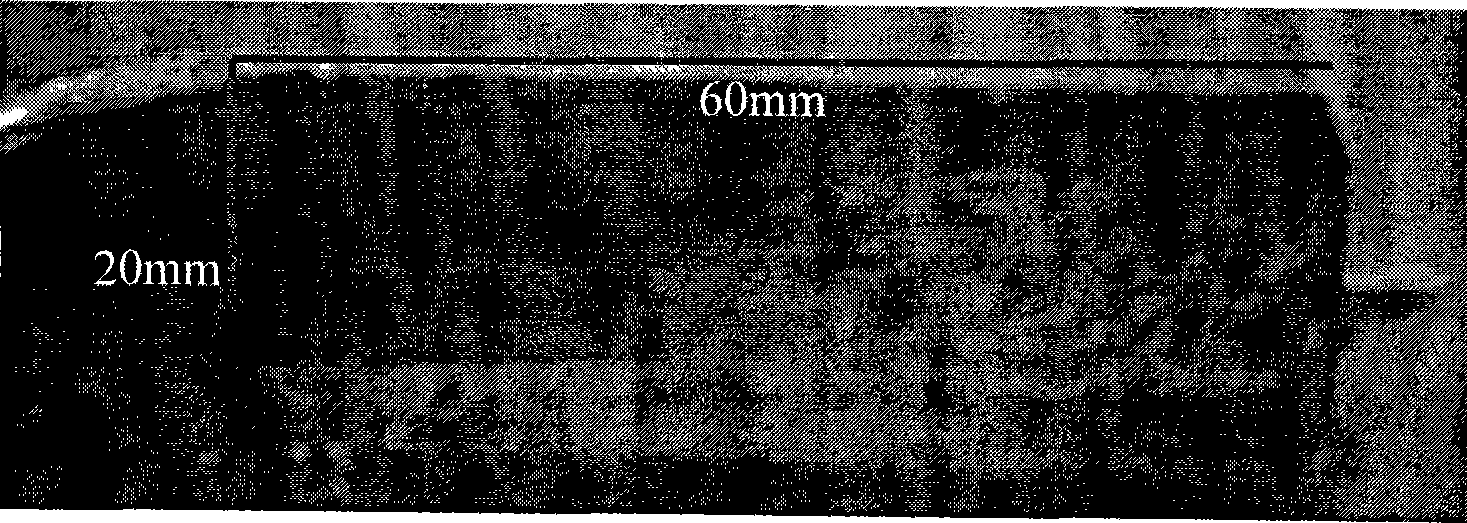

[0017] Specific implementation mode two: combination figure 1 , figure 2 Illustrate this embodiment, the precision casting method of the metal mold bottom leakage vacuum suction casting titanium-based alloy described in this embodiment is completed by the following steps: 1. Take 20g of prefabricated Ti6Al4V alloy according to the pouring quantity requirement; 2. Put the weighed Ti6Al4V alloy into the non-consumable electrode electric arc furnace for melting. The melting steps are as follows: 1. Turn on the circulating water to cool the non-consumable electrode arc furnace, and turn on the mechanical pump to cool the non-consumable electrode arc furnace. The furnace is pre-evacuated to make the vacuum in the furnace reach 5.0×10 -1 Pa, then turn on the molecular pump to further evacuate until the vacuum degree reaches 6.0×10 -3 Turn off the molecular pump at Pa; 2. Fill in the inert gas argon until the pressure in the furnace body reaches 380mm Hg (0.05MPa) and close the g...

specific Embodiment approach 3

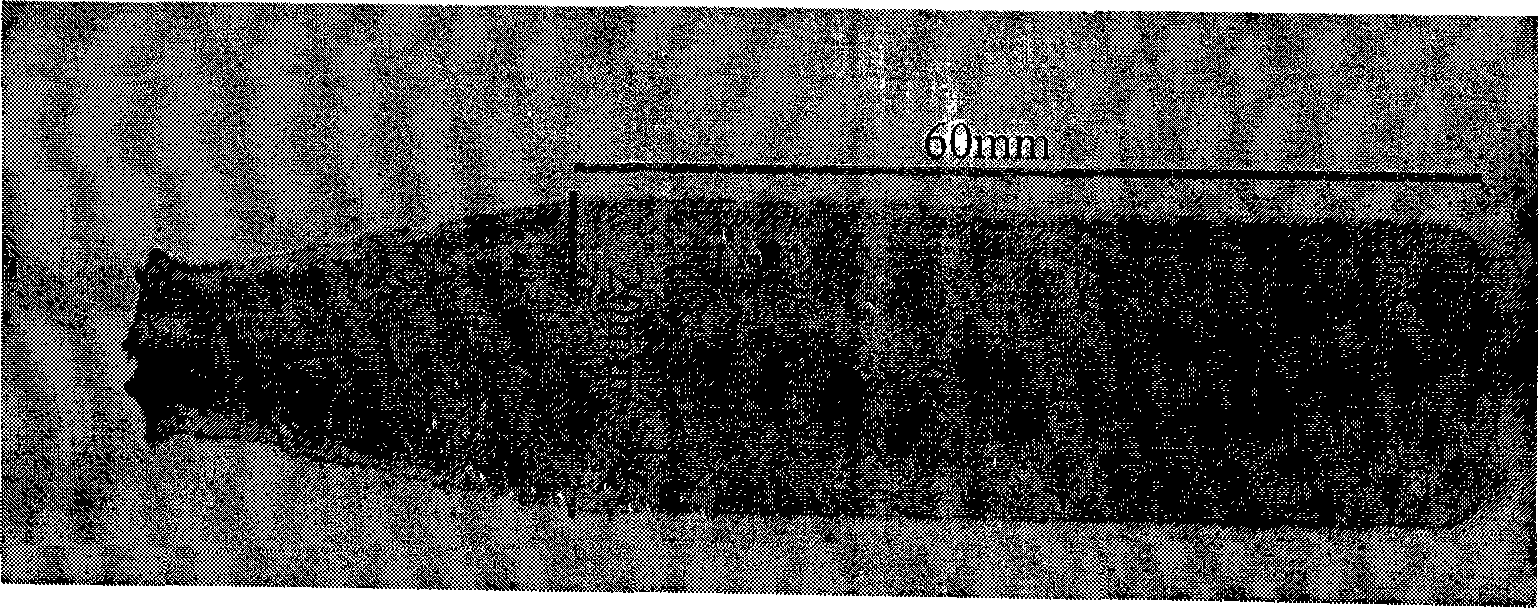

[0018] Specific implementation mode three: combination figure 1 Fig. 3 and Figure 4 Illustrate this embodiment, the investment casting method of the metal type bottom drain type vacuum suction casting titanium-based alloy described in this embodiment is completed by the following steps: one, the Ti-47Al-5Nb-0.5Si alloy is melted, The nominal chemical composition is: titanium 11.4g, aluminum 5.35g, niobium 2.3g, silicon 0.07g; 2. Put the prepared alloy into a non-consumable electrode electric arc furnace for smelting. The smelting steps are as follows: 1. Turn on the circulating water Cool the non-consumable electrode electric arc furnace, and at the same time turn on the mechanical pump to pre-evacuate the non-consumable electrode electric arc furnace, so that the vacuum degree in the furnace body reaches 5.0×10 -1 Pa, then turn on the molecular pump to further evacuate until the vacuum degree reaches 6.0×10 -3Turn off the molecular pump at Pa; 2. Fill in the inert gas argo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com