Preparation method of inorganic material-coated phase change microcapsule, product prepared thereby and application of product

A technology of phase change microcapsules and inorganic materials, applied in the field of energy storage materials, can solve the problems of limited application and difficult realization of phase change microcapsules

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0063] Take 10 g of tetrabutyl titanate, 2 g of aminopropyltrimethoxysilane and 1 g of phenyltrimethoxysilane and add them into 30 g of molten n-octadecane, and mix them thoroughly to form a dispersed phase. Get 2.5g of sodium lauryl sulfate and add it to 50g of water as the continuous phase, and use the concentration of 2mol / L hydrochloric acid to adjust the pH of the continuous phase to 2.5. The dispersed phase was added to the continuous phase, and emulsified by ultrasound. The emulsification time was 30 minutes, and the frequency of the ultrasound was 10000 Hz. The obtained emulsion was transferred to a three-necked flask, and reacted at 70° C. for 12 hours under mechanical stirring. The phase change microcapsule dry powder is obtained through separation, washing and further drying.

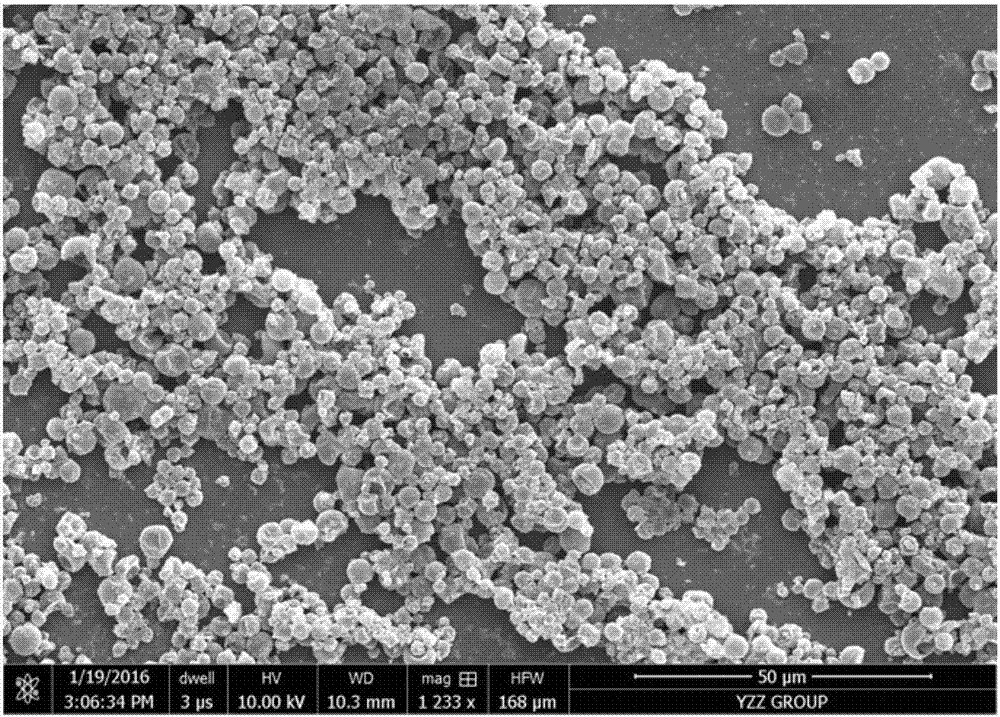

[0064] The scanning electron micrographs of the phase-change microcapsules coated with inorganic materials prepared in this example are as follows: figure 1 shown. from figure 1 It can be ...

Embodiment 2

[0068] Take 6g of tetraethyl orthosilicate, 0.5g of glycidyltrimethoxysilane and 0.5g of phenyltriethoxysilane and add them into 30g of molten octadecane, and mix them thoroughly as the dispersed phase. Add 1g of Tween 80 to 50g of water as the continuous phase. Add the dispersed phase to the continuous phase, use a high-speed shear emulsifier to emulsify at 10,000 rpm for 10 min, transfer the obtained emulsion to a three-necked flask, and react at 70°C for 12 hours under mechanical stirring. The phase change microcapsule dry powder is obtained through separation, washing and further drying.

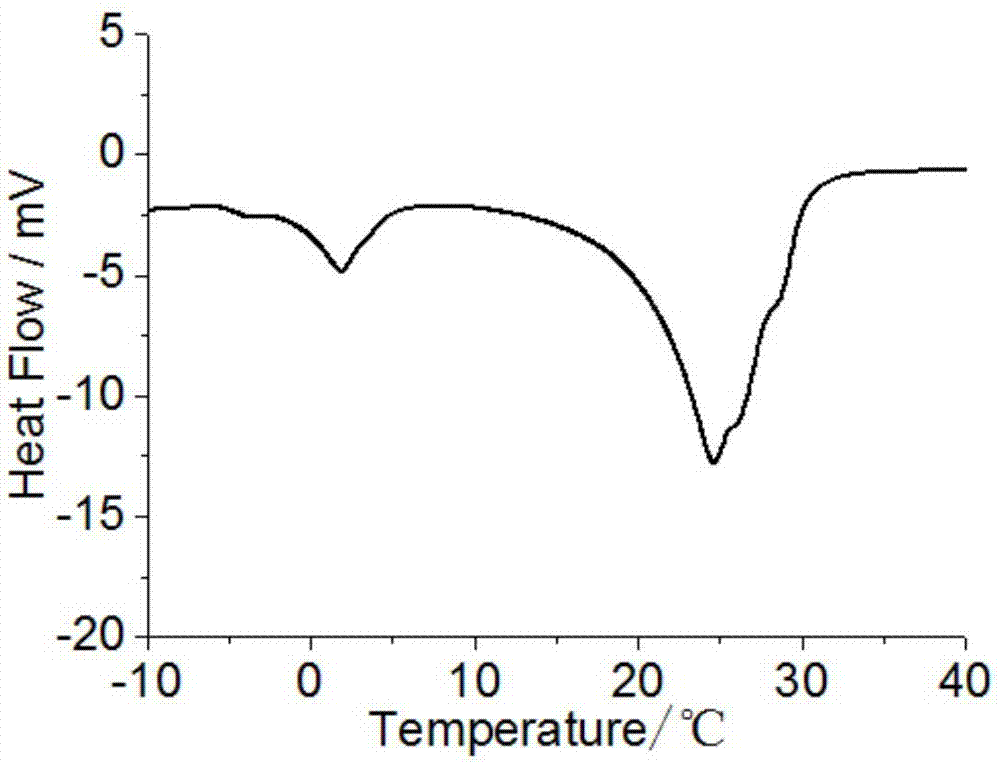

[0069] In the phase-change microcapsules coated with inorganic materials prepared in this example, the mass percentage of the core material in the phase-change microcapsules is 83%; the mass percentage of the wall material in the phase-change microcapsules is 17%; the phase transition temperature of the phase change microcapsules coated with inorganic materials is 20°C; the latent heat ...

Embodiment 3

[0071] Take 10 g of ethyl orthosilicate, 0.5 g of aminopropyltrimethoxysilane and 0.5 g of n-octyltriethoxysilane and add them into 30 g of molten octadecane, and mix them thoroughly as the dispersed phase. Add 1g of Tween 80 to 50g of water as the continuous phase. Add the dispersed phase to the continuous phase, use a high-speed shear emulsifier to emulsify at 10,000 rpm for 10 min, transfer the obtained emulsion to a three-necked flask, and react at 70°C for 12 hours under mechanical stirring. The phase change microcapsule dry powder is obtained through separation, washing and further drying.

[0072] In the phase-change microcapsules coated with inorganic materials prepared in this embodiment, the mass percentage of the core material in the phase-change microcapsules is 85%; the mass percentage of the wall material in the phase-change microcapsules is 15%; the phase transition temperature of the phase change microcapsules coated with the inorganic material is 28°C; the la...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Latent heat of phase change | aaaaa | aaaaa |

| Phase transition temperature | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com