Nodular cast iron material and preparation method thereof

A technology for ductile cast iron and molten iron, applied in the field of ductile iron materials and their preparation, can solve the problems of difficult preparation process, large deviation, and insufficient hardness, and achieve the effects of strong process controllability, low production cost, and good hardness uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

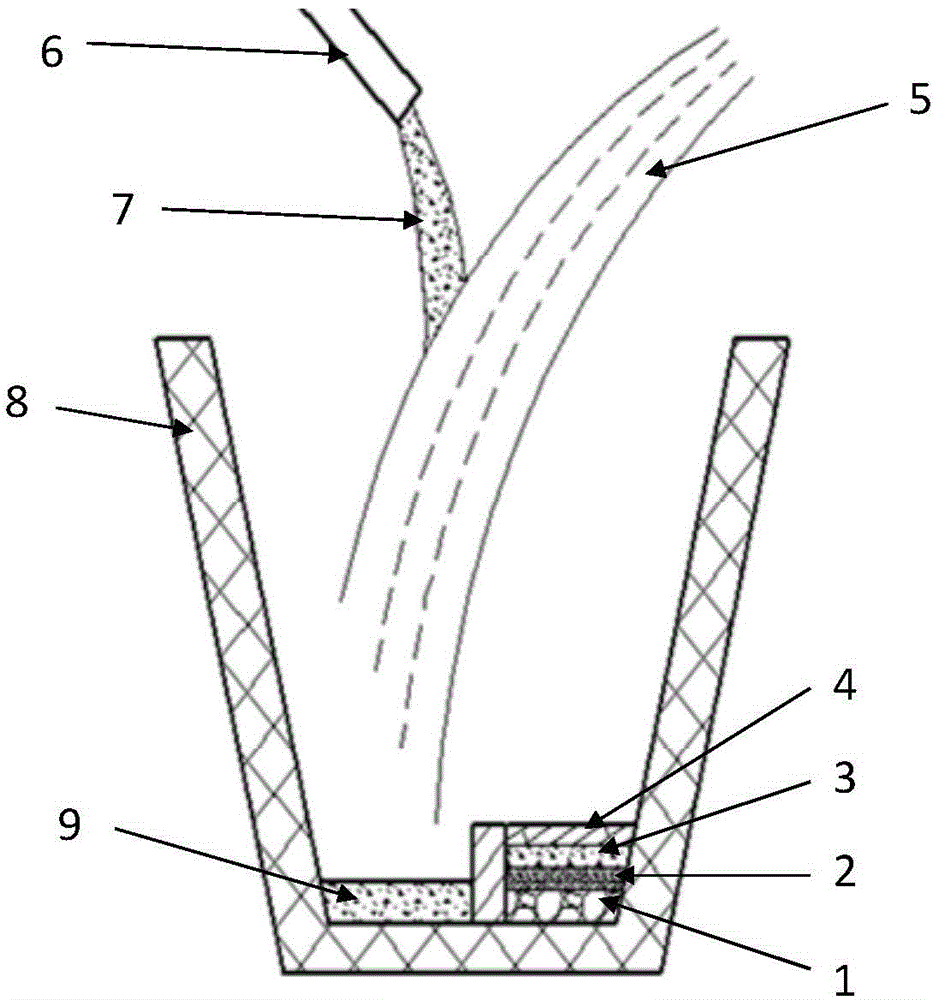

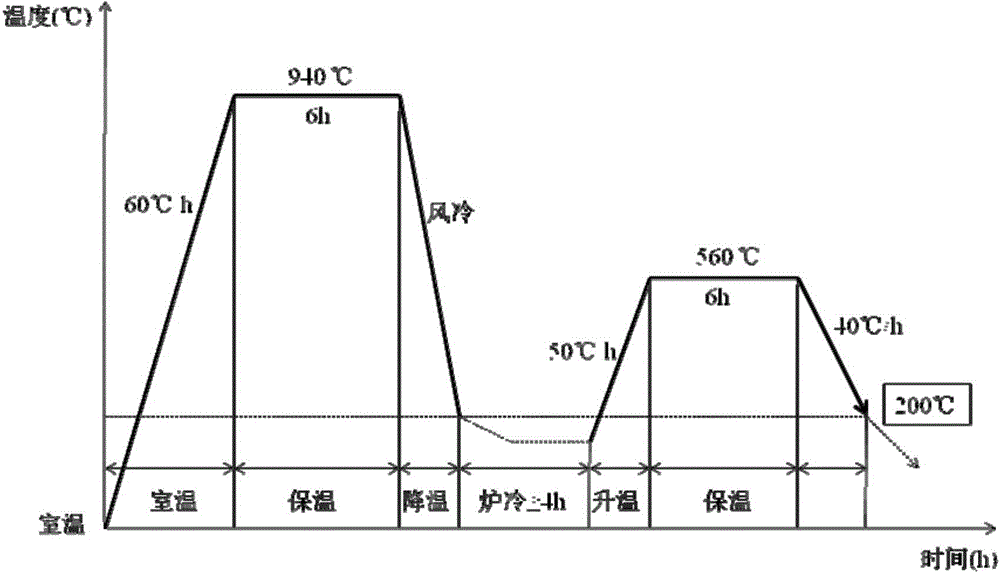

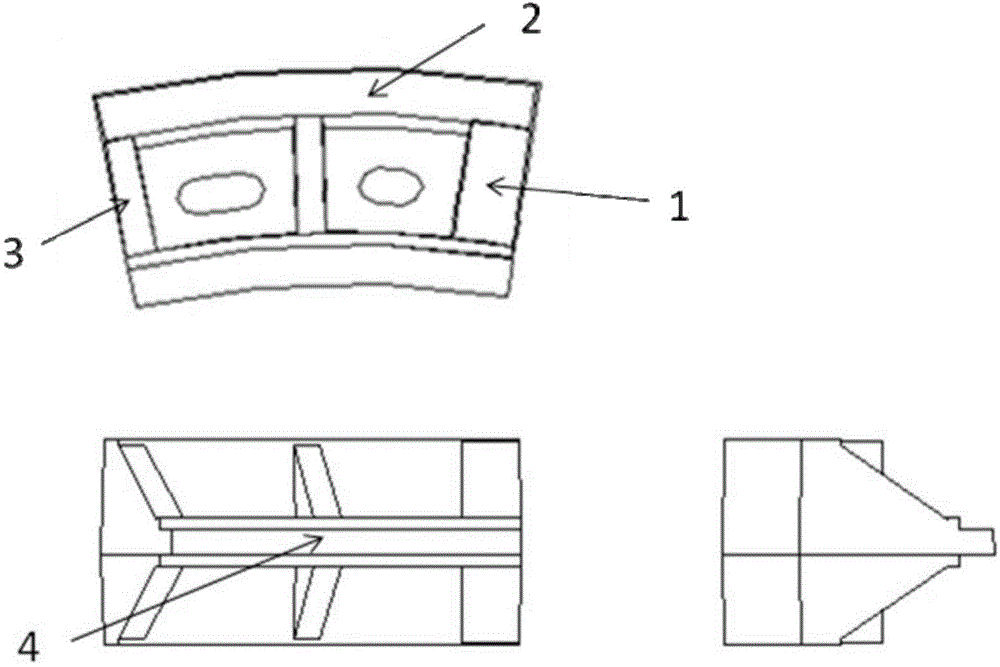

[0027] The preparation method of ductile iron material provided by the present invention may further comprise the steps:

[0028] (1) Weigh the charge, according to the weight percentage, the charge includes: 45%-65% of pig iron, 5%-20% of nodular iron return charge, 30%-45% of scrap steel, 0.4%-0.9% of recarburizer, and 0.6% of ferrosilicon ~1.0%, electrolytic copper 1.2%~1.6%, tin ingot 0.13%~0.16%, antimony iron 0.025%~0.045%. In a preferred embodiment of the present invention, according to the weight percentage, the charge includes: 60% pig iron, 5% nodular iron return charge, 35% steel scrap, 0.7% recarburizer, 0.9% ferrosilicon, 1.3% electrolytic copper, 0.15% tin ingot %, antimony iron 0.035%. For the nodular cast iron material provided by the present invention, the proportion of pig iron is not less than 45%, ensuring that the original molten iron has sufficient nucleation cores; the proportion of scrap steel is controlled above 30%, so that there is sufficient nitrog...

Embodiment 1

[0035] The main chemical composition of the ductile iron material in this embodiment is shown in Table 1.

[0036] Table 1

[0037]

[0038] The performance and metallographic phase of the ductile iron material are shown in Table 2.

[0039]

[0040] The preparation method of the ductile iron material comprises the following steps:

[0041] (1) Weigh the charge for use, and the charge includes: 60% pig iron, 5% ductile iron return charge, 35% scrap steel, 0.7% recarburizer, 0.9% ferrosilicon, 1.3% electrolytic copper, tin ingot according to weight percentage 0.15%, iron antimony 0.035%.

[0042] (2) Add steel scrap, recarburizer, nodular iron return charge, ferrosilicon and pig iron to the electric furnace for smelting in turn, and after complete melting, add electrolytic copper, tin ingot and iron antimony, and raise the temperature to 1410℃~1450℃ Component analysis, after adjusting the components to meet the requirements of Table 3, quickly raise the temperature to ...

Embodiment 2

[0050] The main chemical components and measurement results of the ductile iron material in this embodiment are shown in Table 5. Its preparation method is as follows:

[0051] (1) Weigh the charge for use, and the charge includes: 60% pig iron, 5% ductile iron return charge, 35% scrap steel, 0.7% recarburizer, 0.9% ferrosilicon, 1.3% electrolytic copper, tin ingot according to weight percentage 0.15%, iron antimony 0.035%.

[0052] (2) Add steel scrap, recarburizer, nodular iron return charge, ferrosilicon and pig iron to the electric furnace for smelting in turn, and after complete melting, add electrolytic copper, tin ingot and iron antimony, and raise the temperature to 1410℃~1450℃ Component analysis, after adjusting the components to meet the requirements of Table 3, quickly raise the temperature to 1470°C ~ 1500°C, and keep it warm for 2 ~ 5min.

[0053] (3) Lower the temperature of the molten iron in the furnace to 1420°C to 1460°C, quickly pour the molten iron into t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com