A kind of d-type graphite cast iron and production method thereof

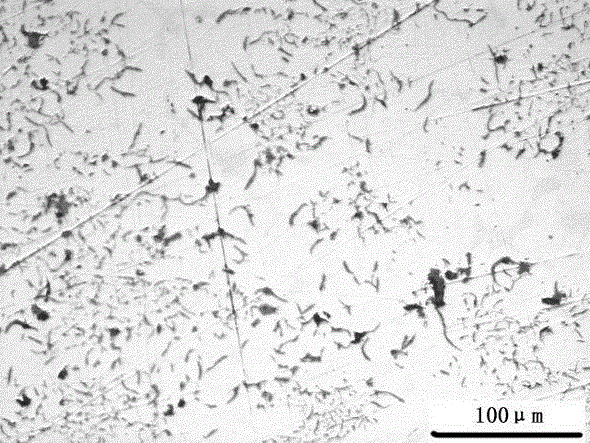

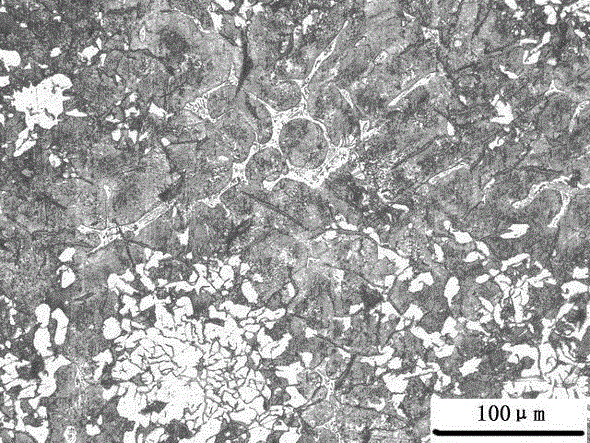

A graphite cast iron and production method technology, applied in the field of graphite cast iron, can solve problems such as reducing carbon solubility, and achieve the effect of narrowing the distance between dendrite arms, developing dendrites, and increasing the number

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0035] A production method of D-type graphite cast iron, comprising the steps of:

[0036]1) Use 500 kg of scrap steel, 13 kg of national standard FeSi75-B ferrosilicon, 14 kg of national standard FeMn63 high-carbon ferromanganese, 4 kg of electrolytic copper plate, 1.6 kg of national standard FeTi30-B ferro-titanium, and a graphite recarburizer with a carbon content of 98%. 16 kg, and 0.5 kg of iron sulfide with a sulfur content of 40% are added to an intermediate frequency induction furnace to melt into molten iron, and the scrap steel is the national standard No. 10 low-carbon scrap steel without rust and oil;

[0037] 2) Heat the molten iron to 1550°C, and blow argon gas into the molten iron at this temperature. The blowing depth is one-third of the depth of the furnace bottom, and the blowing time is 8 minutes. During the blowing...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com