Inorganic phase-changing energy storage material

A technology of energy storage materials and inorganic phase change, applied in heat exchange materials, chemical instruments and methods, etc., can solve the problems of phase separation and corrosion, high degree of subcooling of crystal water, etc., and achieve high heat of solution and good flow. The effect of low cost and low cost of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

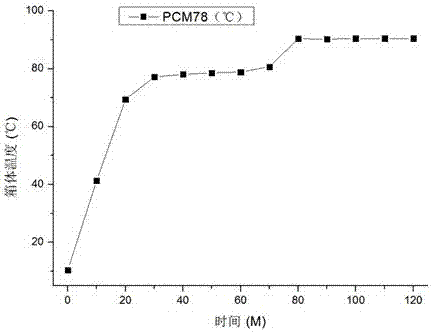

experiment example 1

[0025] Weigh 100g of barium hydroxide octahydrate, 5.44g of expanded graphite, 2.70g of potassium dihydrogen phosphate, and 0.55g of deionized water and place them in a reaction vessel, and directly store heat on the inorganic phase change energy storage material of the present invention through a continuous relay. Stirring was continued in the reactor for 30 minutes, and the temperature was controlled at 85°C for melting until the samples were mixed uniformly to obtain a phase-change energy storage material. The measured enthalpy value of the inorganic phase change energy storage material is 580kJ / L, and the density reaches 2.07g / cm 3 .

experiment example 2

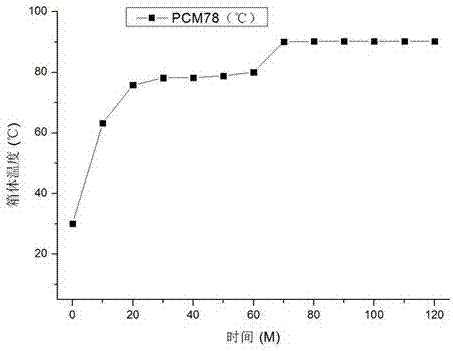

[0027] Weigh 100g of barium hydroxide octahydrate, 3.13g of calcium chloride dihydrate, and 1.04g of gelatin, and place them in a reaction vessel, and directly store heat on the inorganic phase change energy storage material of the present invention through a continuous relay. Stirring was continued in the reactor for 30 minutes, and the temperature was controlled at 85°C for melting until the samples were mixed uniformly to obtain a phase-change energy storage material. The measured enthalpy value of the inorganic phase change energy storage material is 526kJ / L, and the density reaches 1.98g / cm 3 .

experiment example 3

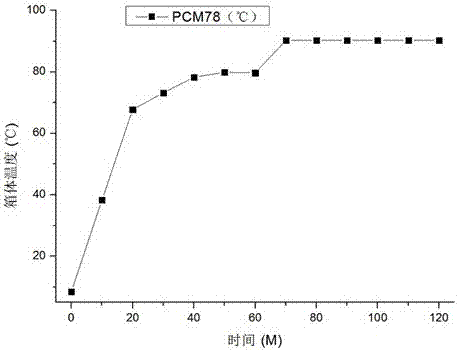

[0029] Weigh 100g of sodium acetate trihydrate, 1.06g of gelatin, 1.06g of potassium dihydrogen phosphate, 0.53g of deionized water, and 3.17g of borax, and place them in the reaction vessel, and directly carry out the inorganic phase change energy storage material of the present invention through a continuous relay. Heat storage. Stirring was continued in the reactor for 30 minutes, and the temperature was controlled at 85°C for melting until the samples were mixed uniformly to obtain a phase-change energy storage material. The measured enthalpy value of the inorganic phase change energy storage material is 312kJ / L, and the density reaches 1.40g / cm 3 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com