Nano refrigerant hydrate phase change cold-storage working substance and preparation thereof

A phase-change cold storage and refrigerant technology, which is applied in the direction of chemical instruments and methods, heat exchange materials, etc., can solve the practical application of refrigerant gas hydrate cold storage technology, two-phase contact restrictions, increase equipment costs and energy consumption, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

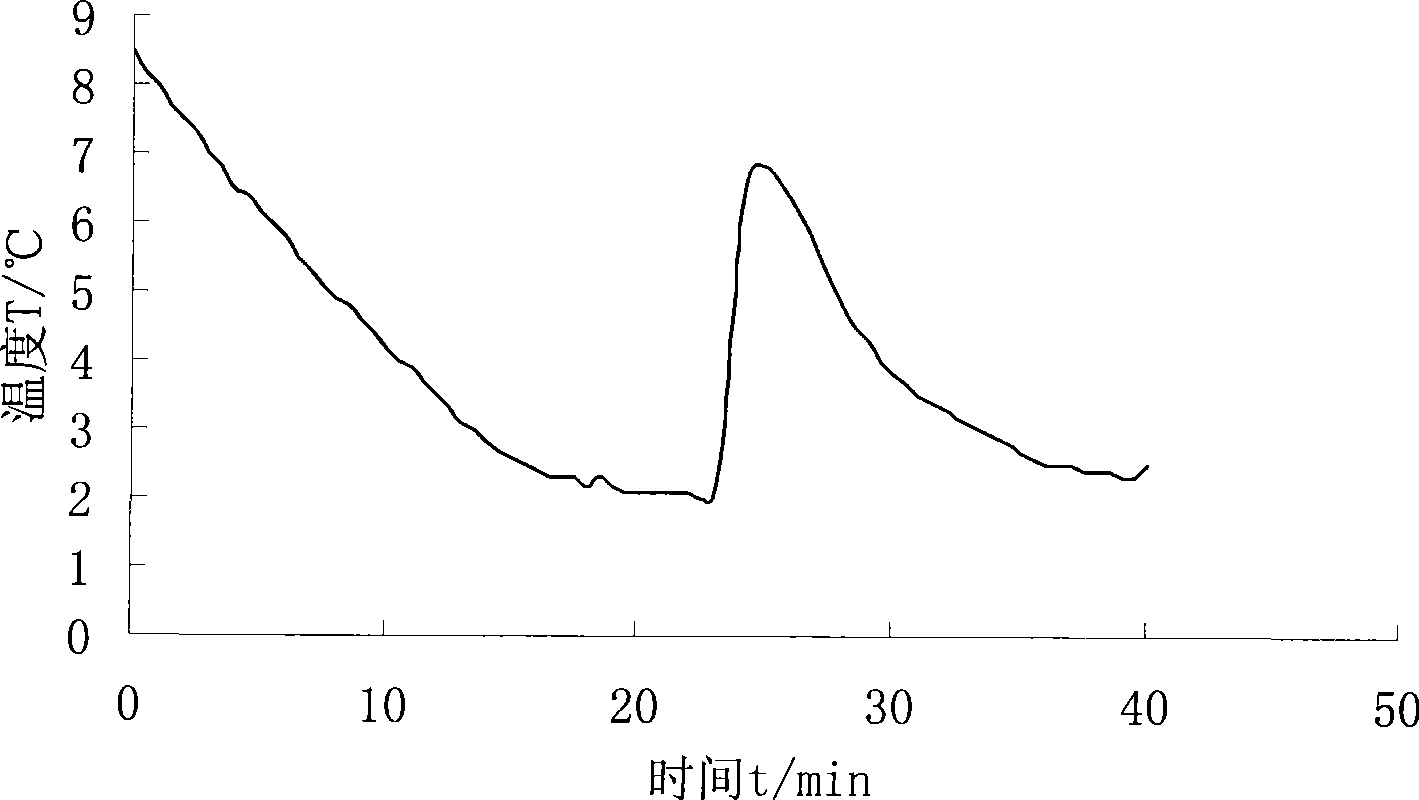

[0025] Embodiment 1: first sodium dodecyl sulfate (SDS) is dissolved in water, and the obtained SDS aqueous solution that contains mass percent concentration is 10%; Then lecithin is dissolved in the refrigerant R141b, obtained contains mass percent The lecithin R141b solution with a concentration of 5% was added dropwise to the SDS aqueous solution at a mass ratio of 1:100 in a 20°C water bath, and the solution was stirred until the solution changed from turbid to transparent. Put the test tube containing the above-mentioned clear solution into a constant temperature bath at 0.8°C, and figure 1 The hydrate formation curve shows that the temperature for hydrate formation is 2°C, that is, the degree of supercooling is 6.4°C, and the required induction time is 23.5 minutes. The reaction speed is faster.

Embodiment 2

[0026] Embodiment 2: 1) at first surfactant cetyl trimethyl ammonium bromide (CTAB) and auxiliary surfactant butanol are dissolved in water, the aqueous solution of making surfactant, the quality of this surfactant is 100% Sub-concentration is the maximum solubility of the surfactant in water, and the mass percentage concentration of the co-surfactant is the maximum solubility of the co-surfactant in water;

[0027] 2) Then CCIF 2 CCIF 2 Add (R114) dropwise into the aqueous solution of surfactant, stir until the solution turns from turbid to clear, its dissolution temperature is 0.1°C to below the normal boiling point of the refrigerant, and the mass ratio of the refrigerant solution to the aqueous surfactant solution is 1 :100.

Embodiment 3

[0028] Embodiment 3: 1) firstly, surfactant carboxylate type ammonium oleic acid triacetate was dissolved in water to obtain an aqueous solution of surfactant, and the mass percent concentration of the surfactant was 8%;

[0029] 2) Then CHF 2 -O-CHF 2 (RE134) is added dropwise into the aqueous solution of surfactant, and stirred until the solution turns from turbid to clear, and its dissolution temperature is 0.1°C to below the normal boiling point of the refrigerant, and the mass ratio of refrigerant solution to the aqueous solution of surfactant is refrigeration Until the mixed transparent or translucent system of the surfactant solution and the aqueous solution of the surfactant starts to appear turbid.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com