Microcapsule composite phase change material based on inorganic hydrous salt as well as preparation method and application thereof

A technology of composite phase change materials and inorganic hydrated salts, applied in heat exchange materials, chemical instruments and methods, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

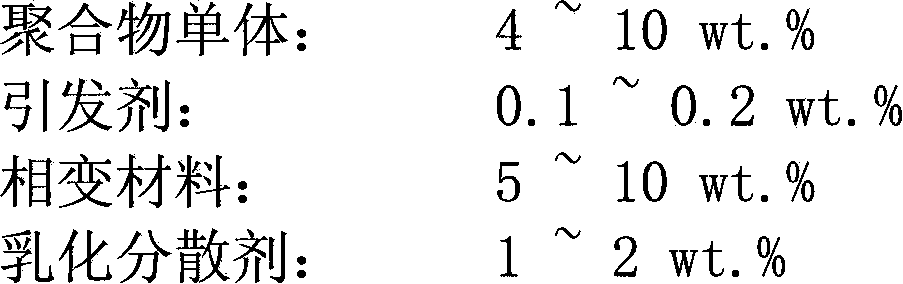

Method used

Image

Examples

Embodiment 1

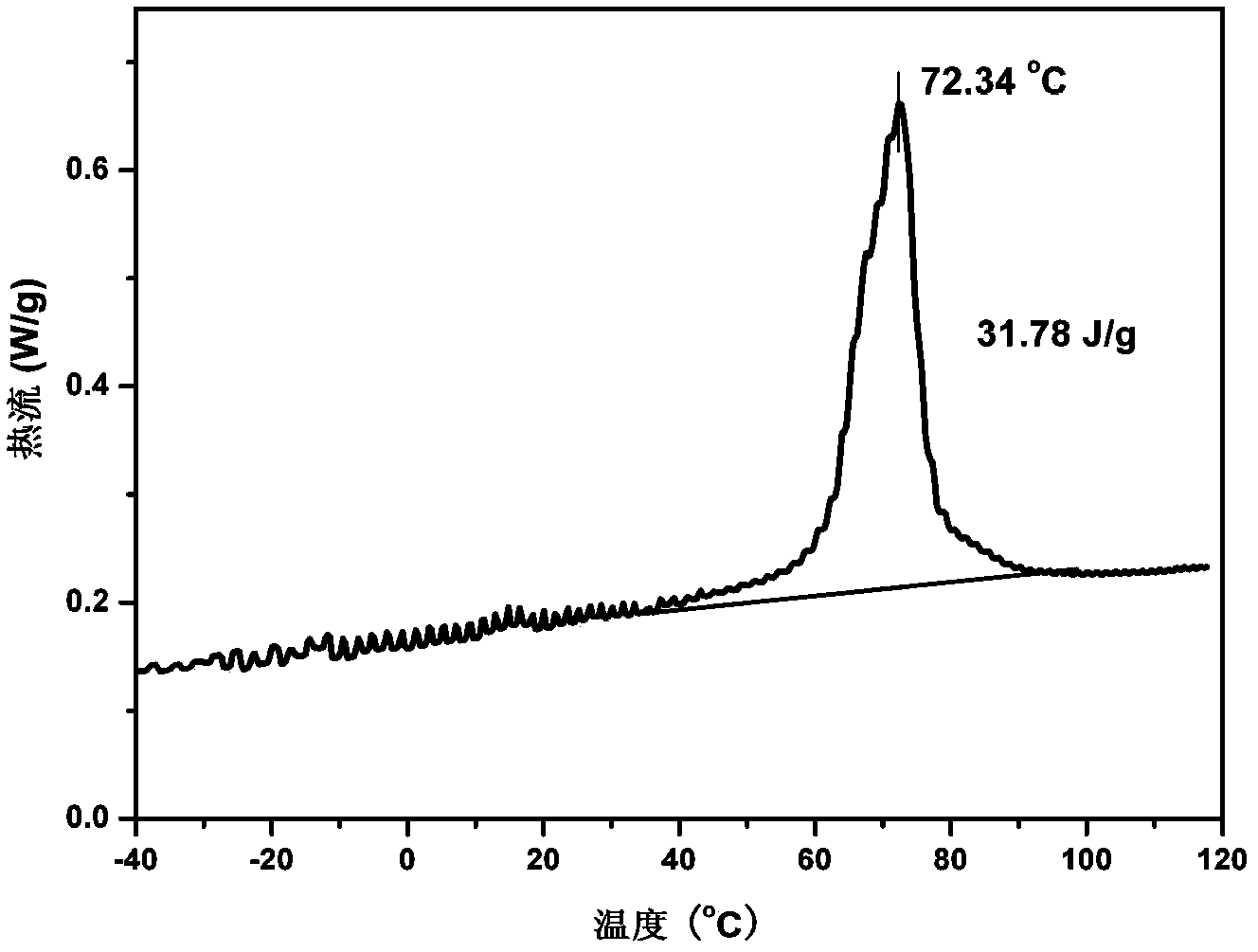

[0030] 6.0kg CaCl 2 ·6H 2 0. Add 10 kg of water and 0.1 kg of potassium persulfate to 100 kg of a cyclohexane solution containing 2wt.% sodium dodecylsulfonate in mass percent, and stir and emulsify at a speed of 8000 rpm for 3 h in a constant temperature water bath at 35 ° C. Forms a stable W / O emulsion. 4.0kg styrene monomer is added in this W / O emulsion, is heated up to 70 ℃, initiates polymerization reaction, and initiator constantly diffuses to the interface of micelle and solvent, polymerizes step by step, reacts 24h, obtains white product solution, will The solution is continuously washed with acetone for several times, and then cleaned with deionized water, filtered by suction for many times, and dried to obtain the product.

[0031] In this way, the inorganic hydrate salt microcapsule composite phase change material coated with polystyrene wall material is obtained. Its phase transition temperature is 72.34°C, and its phase transition enthalpy is 31.78 J / g.

Embodiment 2

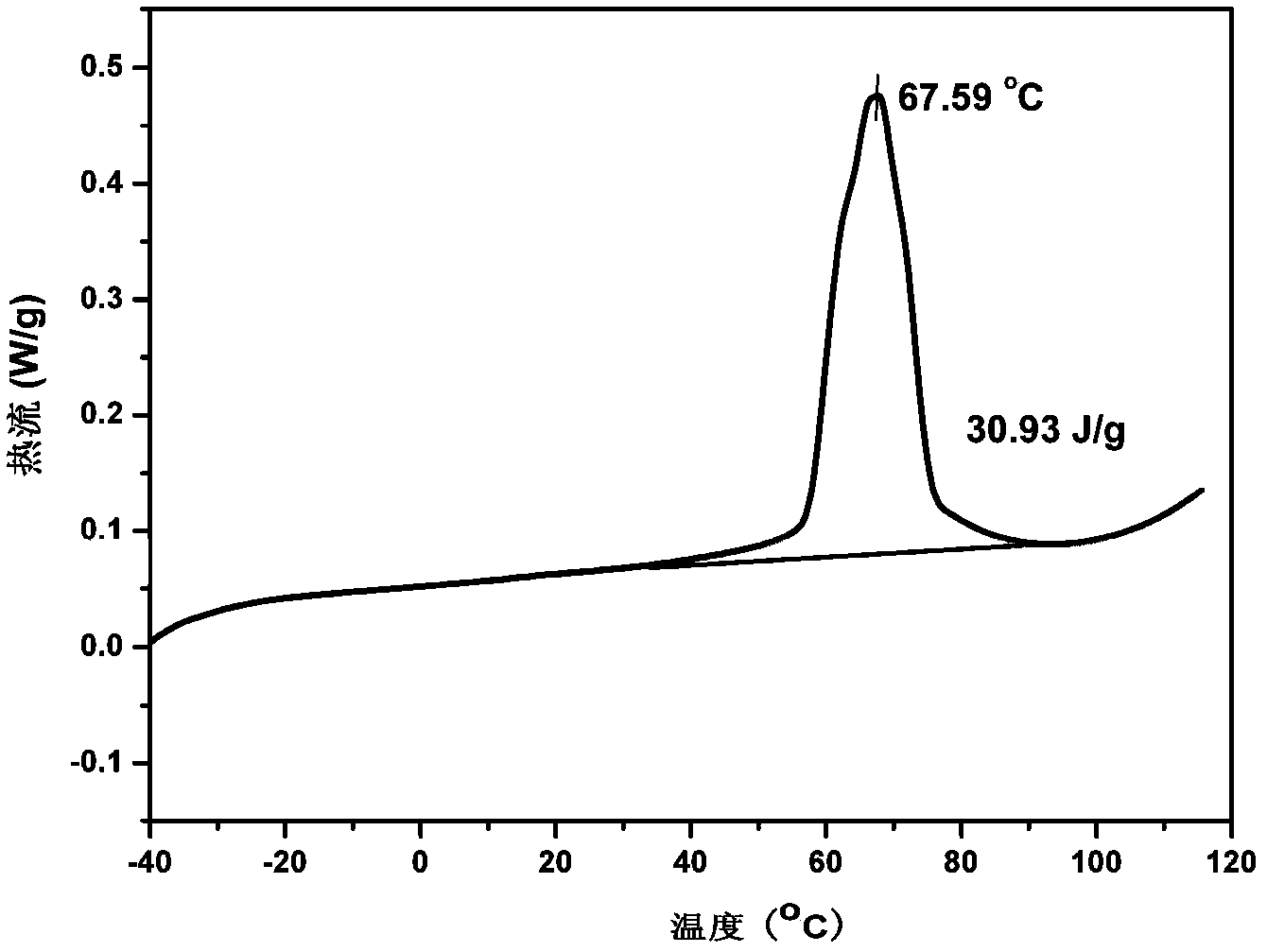

[0033] 6.0kg CaCl 2 ·6H 2 O, 100mL of water and 0.1kg of potassium persulfate were added to 10.0kg of cyclohexane solution containing 0.2wt.% sodium lauryl sulfate by mass percentage, in a constant temperature water bath at 35°C, stirred and emulsified at a speed of 8000rpm for 3h , forming a stable W / O emulsion. 4.0kg styrene monomer is added in this W / O emulsion, is heated up to 70 ℃, initiates polymerization reaction, and initiator constantly diffuses to the interface of micelle and solvent, polymerizes step by step, reacts 24h, obtains white product solution, will The solution is continuously washed with acetone for several times, and then cleaned with deionized water, filtered by suction for many times, and dried to obtain the product.

[0034] In this way, the inorganic hydrate salt microcapsule composite phase change material coated with polystyrene wall material is obtained. Its phase transition temperature is 67.59°C, and its phase transition enthalpy is 30.93 J / g....

PUM

| Property | Measurement | Unit |

|---|---|---|

| phase transition temperature | aaaaa | aaaaa |

| phase transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com