Super-hydrophobic microcapsule made from phase-change materials and preparation method of super-hydrophobic microcapsule

A technology of phase change materials and microcapsules, which is applied in the field of superhydrophobic microcapsules of phase change materials and its preparation, and coating of phase change materials. , complex polymer process and other issues, to achieve excellent thermal stability, excellent thermal storage and release capabilities, and easy mass production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

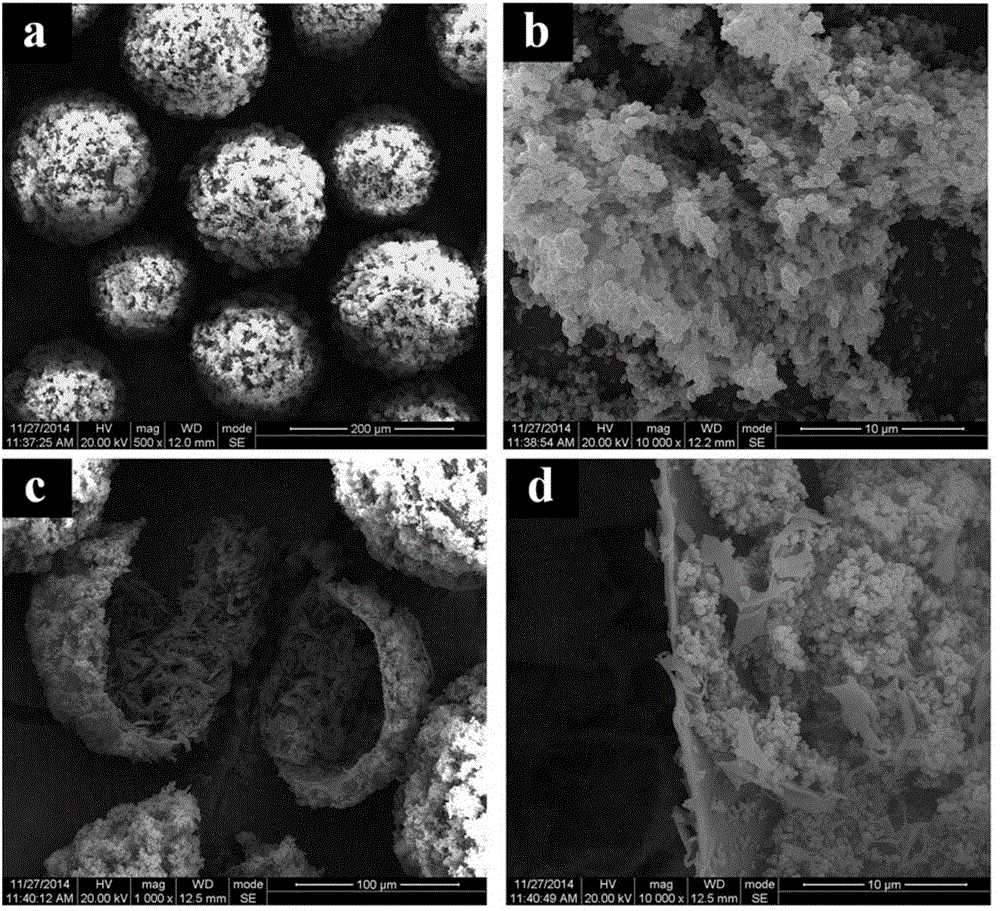

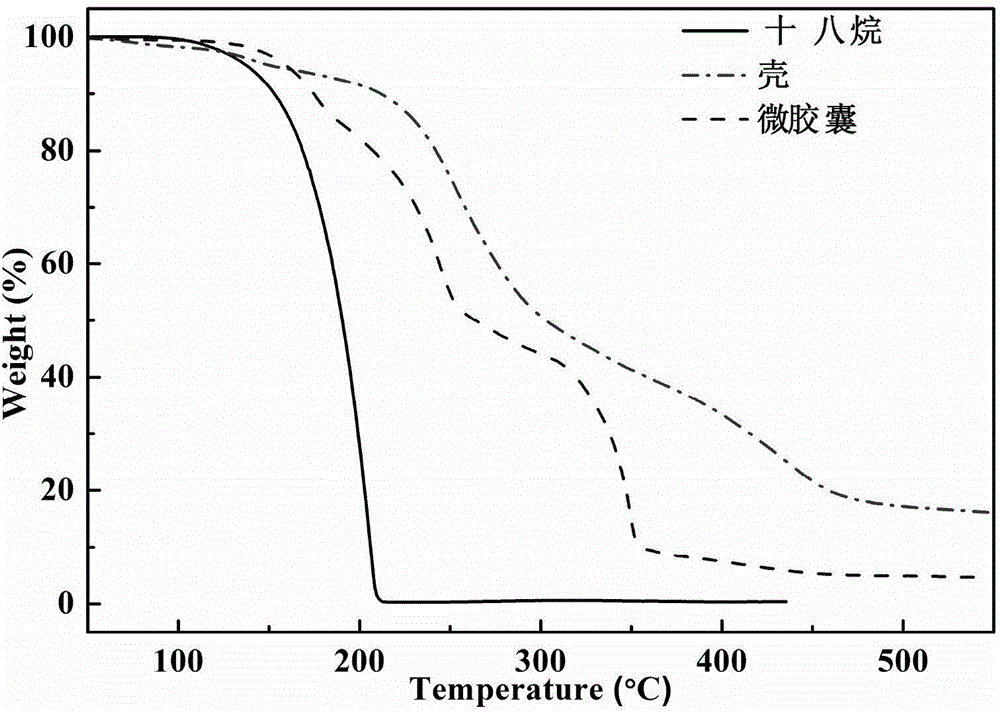

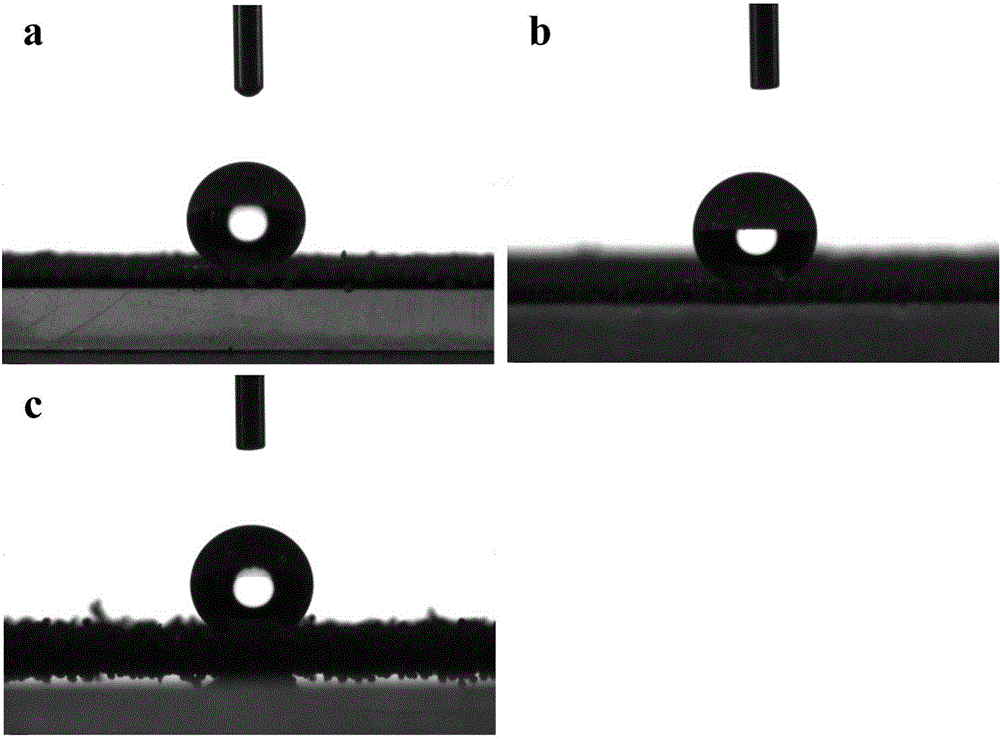

[0031] A preparation method of phase-change material superhydrophobic microcapsules, comprising the following steps:

[0032] Step 1. Preparation of the shell material prepolymer: Mix 2.5 g of urea and 6.33 g of 37% formaldehyde aqueous solution by mass percentage, adjust its pH to 8 with 1 mol / L sodium hydroxide aqueous solution, and stir and react at 70° C. for 1 h. A colorless transparent liquid is obtained, which is the aqueous solution of the shell material urea-formaldehyde prepolymer; the mass ratio of urea to 37% formaldehyde aqueous solution is 1:2.532;

[0033] Step 2. Preparation of the core material: Heat, stir and mix 9g of octadecane and 1g of hexamethylene diisocyanate at 50°C for 30 minutes until uniform and transparent to obtain the core material; the mass ratio of octadecane to hexamethylene diisocyanate 9:1;

[0034] Step 3, the preparation of microcapsules: the whole urea-formaldehyde prepolymer aqueous solution that step 1 obtains and 75mL containing the ...

Embodiment 2

[0040] A preparation method of phase-change material superhydrophobic microcapsules, comprising the following steps:

[0041] Step 1. Preparation of the shell material prepolymer: Mix 2.5 g of urea and 6.33 g of 37% formaldehyde aqueous solution by mass percentage, adjust its pH to 8 with 1 mol / L sodium hydroxide aqueous solution, and stir and react at 70° C. for 1 h. A colorless transparent liquid is obtained, which is the aqueous solution of the shell material urea-formaldehyde prepolymer; the mass ratio of urea to 37% formaldehyde aqueous solution is 1:2.532;

[0042] Step 2. Preparation of the core material: Heat, stir and mix 9g of octadecane and 1g of hexamethylene diisocyanate at 50°C for 30 minutes until uniform and transparent to obtain the core material; the mass ratio of octadecane to hexamethylene diisocyanate 9:1;

[0043] Step 3, the preparation of microcapsules: the whole urea-formaldehyde prepolymer aqueous solution that step 1 obtains and 75mL containing the ...

Embodiment 3

[0049] A preparation method of phase-change material superhydrophobic microcapsules, comprising the following steps:

[0050]Step 1. Preparation of the shell material prepolymer: Mix 2.5 g of urea and 6.33 g of 37% formaldehyde aqueous solution by mass percentage, adjust its pH to 8 with 1 mol / L sodium hydroxide aqueous solution, and stir and react at 70° C. for 1 h. A colorless transparent liquid is obtained, which is the aqueous solution of the shell material urea-formaldehyde prepolymer; the mass ratio of urea to 37% formaldehyde aqueous solution is 1:2.532;

[0051] Step 2. Preparation of the core material: Heat, stir and mix 9g of octadecane and 1g of hexamethylene diisocyanate at 50°C for 30 minutes until uniform and transparent to obtain the core material; the mass ratio of octadecane to hexamethylene diisocyanate 9:1;

[0052] Step 3, preparation of microcapsules: the whole urea-formaldehyde prepolymer aqueous solution obtained in step 1 and 75mL have a mass percent c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com