Power battery thermal management system with functions of efficient heat dissipation and efficient heating

A thermal management system and power battery technology, applied in the direction of batteries, secondary batteries, circuits, etc., can solve the problems of low temperature performance, failure to ensure temperature consistency between batteries, complex structure, etc., and achieve a simple overall structure The effect of stability, high machinability, and broad market prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

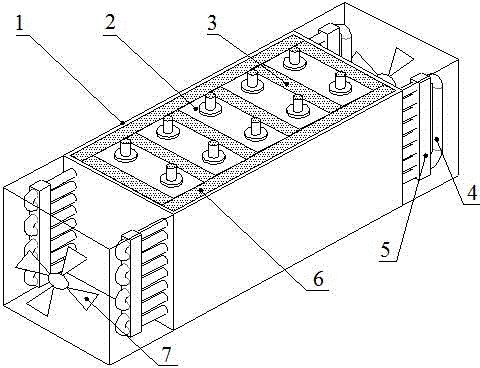

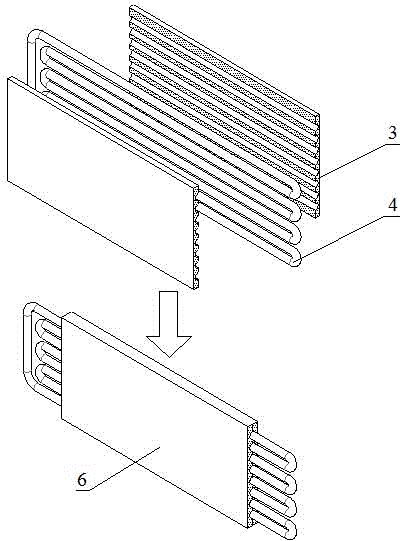

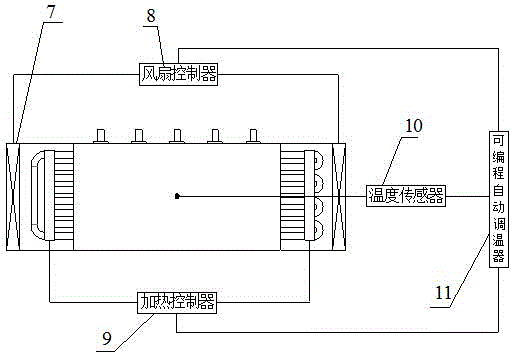

[0025] Specific embodiments: The power battery thermal management system with efficient heat dissipation and heating functions in this embodiment includes a power battery box and a thermal management control system; the power battery box includes a battery module shell 1, a battery cell 2, and a composite phase change material Plate 3, heat pipe 4, heating device 5, composite phase change material heat pipe coupling assembly 6, cooling fan 7. First, several battery cells 2 placed in the battery module casing are arranged adjacently to form a battery pack, and a composite phase-change material plate is sandwiched between two adjacent single cells and the outermost battery surface in the width direction of the battery pack 3. Composite phase-change material heat pipe coupling assemblies 6 are provided on both sides of the battery pack. The heat pipes of the composite phase-change material heat pipe coupling assemblies 6 protrude from the through holes on the battery module casing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com