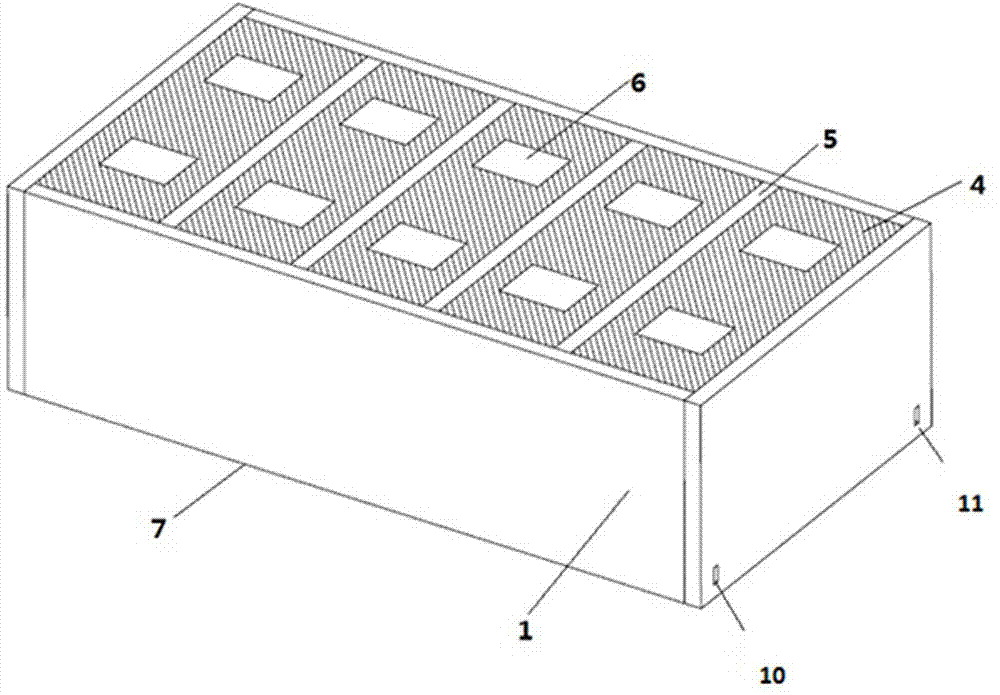

Water cooling and composite phase change material combined power battery heat dissipating device

A technology of composite phase change materials and power batteries, which is applied in the direction of batteries, secondary batteries, circuits, etc., can solve the problems of poor temperature consistency and low heat dissipation efficiency, and achieve good consistency, high heat dissipation rate, and convenient operation and maintenance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

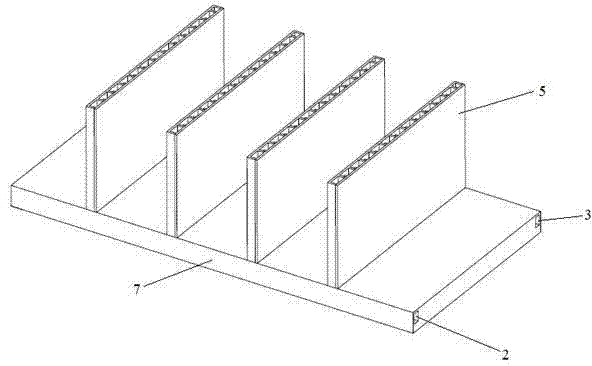

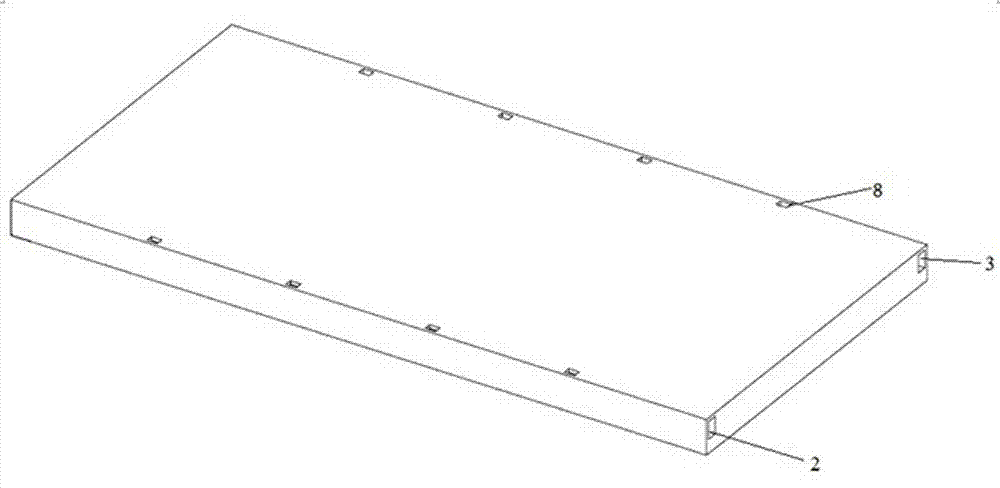

Method used

Image

Examples

Embodiment 1

[0035] Tetradecane (molecular formula: C 24 h 50 ) and expanded graphite composite phase change material 4, its phase transition temperature is 50°C, where C 24 h 50The mass fraction is 90%, and the phase change material is solid at room temperature. Select 15 3.2V20Ah single batteries, and use the series connection to form a battery module. When the battery module is discharged with high power, the temperature of the battery monomer rises rapidly, and its heat is transferred to the composite phase change material through the battery shell. When the temperature is high At 50°C, the composite phase change material 4 absorbs heat and undergoes a solid-liquid phase transition, but the composite phase change material 4 still maintains solid properties and stores heat, thereby realizing heat dissipation and cooling of the battery cell and controlling the temperature of the battery cell When the ambient temperature is 25°C and the discharge time is 20s, the surface temperature of...

Embodiment 2

[0037] Using lauric acid (molecular formula: CH 3 (CH 2 ) 10 COOH) and expanded graphite composite phase change material 4, its phase transition temperature is 43 °C, where CH 3 (CH 2 ) 10 The mass fraction of COOH is 87%, and the phase change material is solid at room temperature. Select 15 3.2V20Ah single batteries, and adopt the method of connecting in series to form a battery pack module; when the battery module is discharged with high power, the temperature of the battery monomer rises rapidly, and its heat is transferred to the composite phase change material 4 through the battery shell. When the temperature is higher than 43°C, the composite phase change material 4 absorbs heat and undergoes a solid-liquid phase transition, but the composite phase change material 4 still maintains solid properties and stores heat, thereby realizing heat dissipation and cooling of the battery cell and controlling the temperature of the battery cell. The temperature rises; when the a...

Embodiment 3

[0039] Using palmitic acid (molecular formula: CH 3 (CH 2 ) 14 COOH) and expanded graphite composite phase change material 4, its phase transition temperature is 64 ° C, where CH 3 (CH 2 ) 14 The mass fraction of COOH is 60%, and the phase change material is solid at room temperature. Select 15 3.2V20Ah single batteries, and adopt the method of connecting in series to form a battery pack module; when the battery module is discharged with high power, the temperature of the battery monomer rises rapidly, and its heat is transferred to the composite phase change material 4 through the battery shell. When the temperature is higher than 64°C, the composite phase change material 4 absorbs heat and undergoes a solid-liquid phase transition, but the composite phase change material 4 still maintains solid properties and stores the heat, so as to realize the heat dissipation and cooling of the battery cell and control the temperature of the battery cell. The temperature rises; when...

PUM

| Property | Measurement | Unit |

|---|---|---|

| phase transition temperature | aaaaa | aaaaa |

| phase transition temperature | aaaaa | aaaaa |

| phase transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com