Self temperature adjustment cold mixing bituminous concrete and preparation method thereof

A kind of asphalt concrete, warm and cold technology, applied in the direction of road, road repair, road, etc., can solve the problem of lack of detailed information, no mention of high temperature rutting on asphalt pavement, etc., achieve simple process, prevent high temperature rutting deformation and asphalt aging, prevent The effect of high temperature rutting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

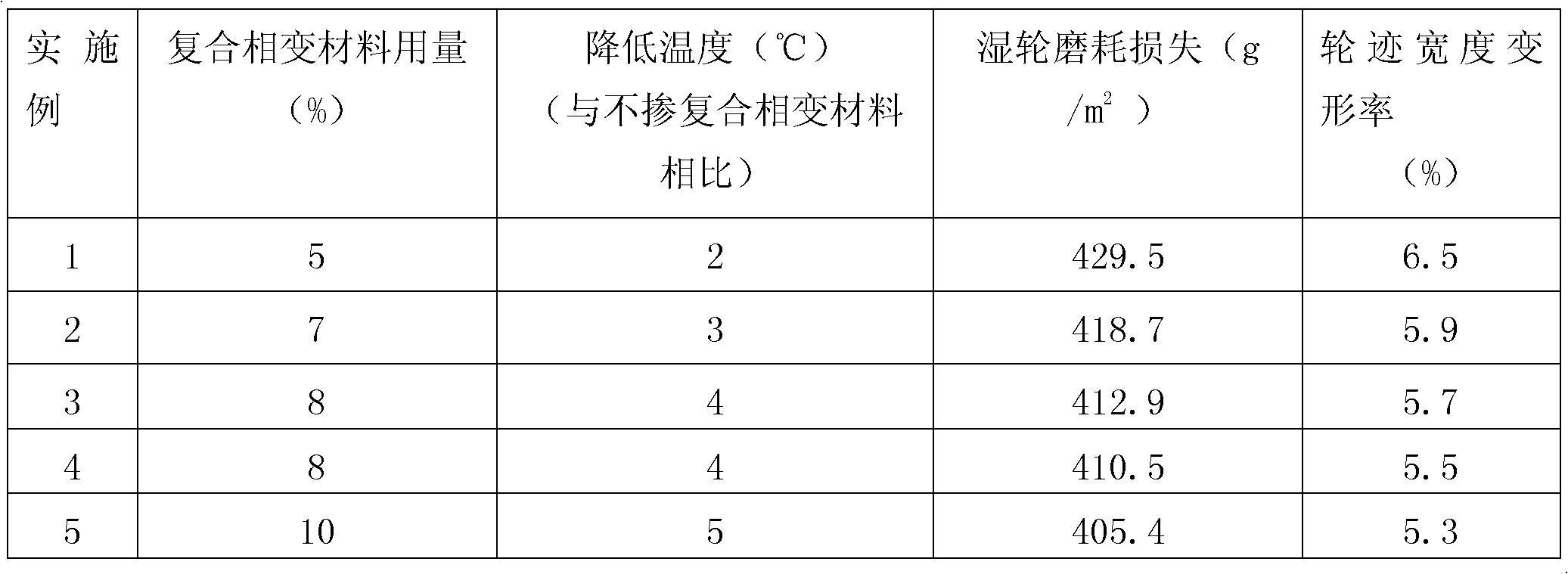

Examples

Embodiment 1

[0024] Self-regulating cold-mix asphalt concrete, which is prepared from aggregates, fillers, composite phase change materials, water and modified emulsified asphalt raw materials, the weight percentage of each raw material is: aggregate 80%, filler 1%, composite phase Variable material 5%, water 8%, modified emulsified asphalt 6%.

[0025] The aggregate is hard, wear-resistant, free of soil impurities, and the sand equivalent is greater than 65%. matching requirements. The aggregates used were graded as follows:

[0026] Sieve hole(mm)

9.5

4.75

2.36

1.18

0.6

0.30

0.15

0.075

Passing rate(%)

100

77.6

57.4

42.4

30.3

21.2

11.8

7.1

[0027] The filler is slaked lime.

[0028] The composite phase change material is made of paraffin and expanded graphite (wherein paraffin is used as a phase change substance, and expanded graphite is used as a support carrier), the mass ratio of ...

Embodiment 2

[0036] The preparation method of self-regulating cold asphalt concrete, it comprises the steps:

[0037] 1) According to the percentage by weight of each raw material: aggregate 75%, filler 2%, composite phase change material 7%, water 9%, modified emulsified asphalt 7%, select aggregate, filler, composite phase change material, water And modified emulsified asphalt, spare;

[0038] The aggregate is hard, wear-resistant, free of soil impurities, and has a sand equivalent of more than 65%. distribution requirements;

[0039] The filler is P.O.42.5 Portland cement;

[0040] The composite phase change material is made of paraffin and expanded graphite (wherein paraffin is used as a phase change substance, and expanded graphite is used as a support carrier), the mass ratio of expanded graphite to paraffin is 1: 8.5, and the phase change of the composite phase change material The temperature is 40-50°C, and the phase change heat is (150-160) kJ / kg;

[0041] The modified emulsif...

Embodiment 3

[0046] The preparation method of self-regulating cold asphalt concrete, it comprises the steps:

[0047]1) According to the percentage by weight of each raw material: aggregate 73%, filler 2%, composite phase change material 8%, water 9%, modified emulsified asphalt 8%, select aggregate, filler, composite phase change material, water And modified emulsified asphalt, spare;

[0048] The aggregate is hard, wear-resistant, free of soil impurities, and has a sand equivalent of more than 65%. distribution requirements;

[0049] The filler is P.O.42.5 Portland cement;

[0050] The composite phase-change material is made of paraffin and expanded graphite (wherein paraffin is used as a phase-change substance, and expanded graphite is used as a support carrier), the mass ratio of expanded graphite to paraffin is 1:8, and the phase change of the composite phase-change material is The temperature is 40-50°C, and the phase change heat is (150-160) kJ / kg;

[0051] The modified emulsifi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Phase transition temperature | aaaaa | aaaaa |

| Heat of phase change | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com