Mesoporous material-based composite phase change heat storage material and preparation method thereof

A technology of composite phase change materials and mesoporous materials, applied in the field of shape-setting phase change heat storage materials, can solve the problems of low content of phase change materials, low latent heat utilization efficiency, low overall latent heat of phase change, etc. The effect of high utilization rate and low cost of latent heat of phase transition and latent heat

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Dissolve 4g of polyethylene glycol (PEG, molecular weight 1500) in 40ml of absolute ethanol, under vigorous stirring, add 1g of SBA-15 mesoporous silicon molecular sieve or MCM-41 mesoporous silicon molecular sieve or active carbon ( AC), stirred at room temperature for 1.0 h, mixed evenly and dried at 80°C for 3 days.

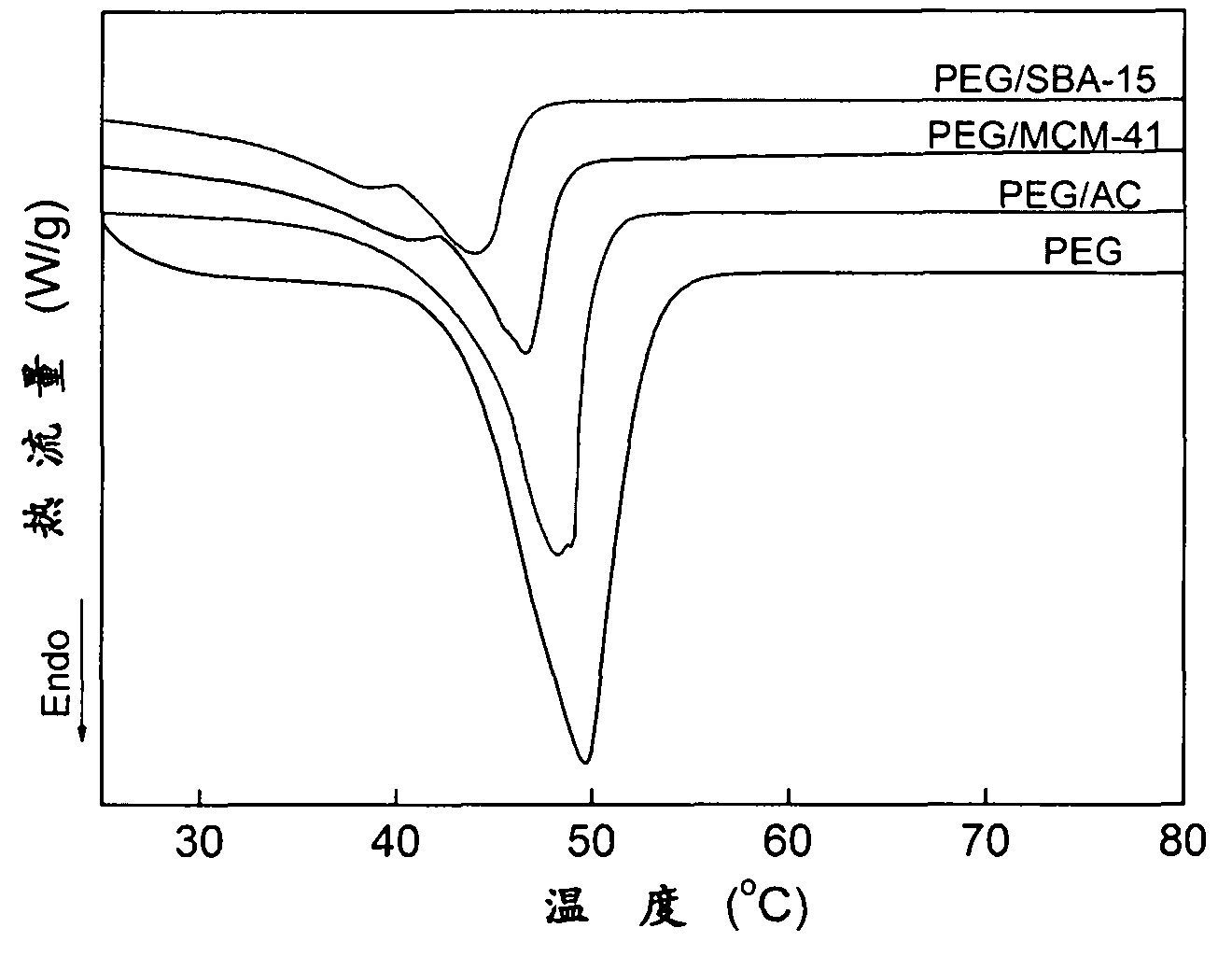

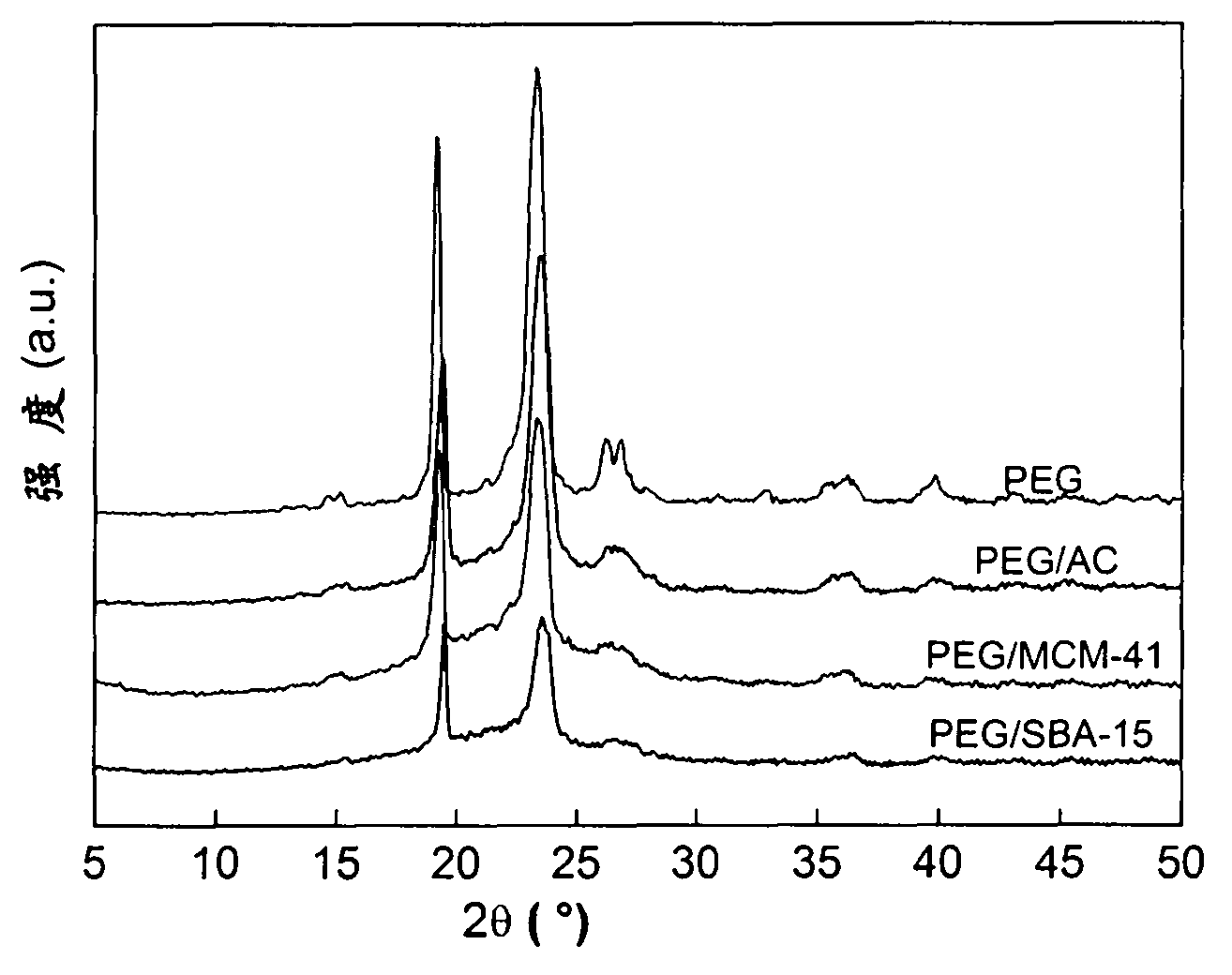

[0039]Implementation results: as shown in Figure 1, different mesoporous material-based composite phase change thermal storage materials have the same crystal phase as the organic phase change material (PEG); Figure 2 is the DSC curve of the composite phase change thermal storage materials, different The phase transition temperature of the mesoporous material-based composite phase change heat storage material is obviously lower than that of the pure organic phase change material PEG. As shown in Table 1, when the content of organic phase change materials in different mesoporous material-based composite phase change heat storage materials is 80wt%, the p...

Embodiment 2

[0043] Dissolve a certain amount of polyethylene glycol (PEG, molecular weight 1500) in absolute ethanol, under strong stirring, add a certain amount of activated carbon (AC) to the above solution, stir at room temperature, mix well and dry at 80°C for 3 sky.

[0044] Table 2: the consumption of raw material in embodiment 2

[0045] PEG1500 content

(wt%)

Absolute ethanol

(ml)

PEG1500(g)

AC(g)

Stirring time (h)

30

15

1.5

3.5

3.5

40

20

2.0

3.0

3.0

50

25

2.5

2.5

2.5

60

30

3.0

2.0

2.0

70

35

3.5

1.5

1.5

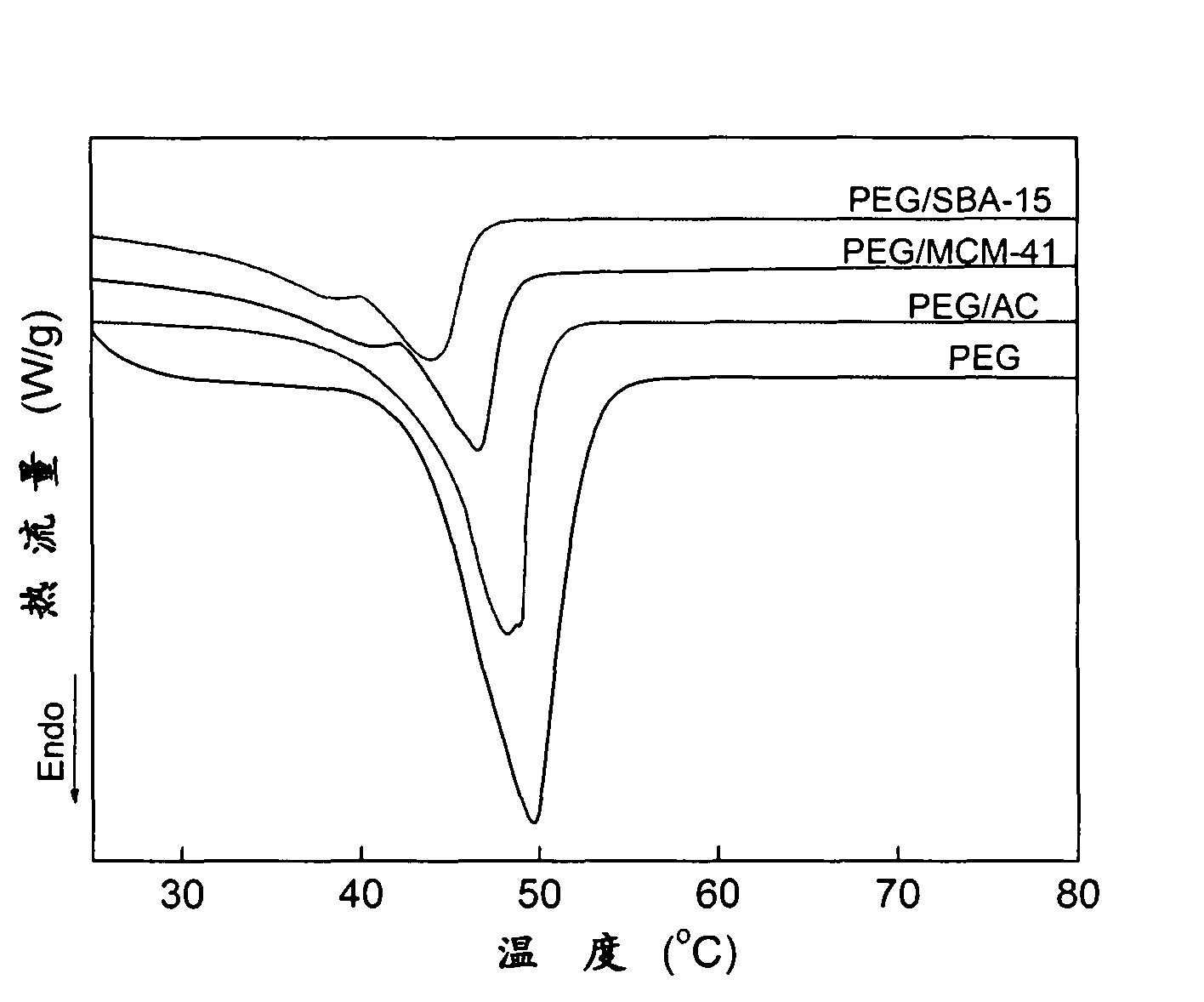

[0046] Implementation results: as shown in Figure 3, the composite phase change heat storage materials with different PEG contents have the same crystal phase as the organic phase change material (PEG) therein; Figure 4 is the DSC of the composite phase change heat storage materials with different P...

Embodiment 3

[0050] Dissolve 3.5g of polyethylene glycol (PEG, molecular weight 1500, 4000, 6000, 10000) in 35ml of absolute ethanol, under vigorous stirring, add 1.5g of activated carbon (AC) to the above solution, and stir at room temperature for 1.5 h, after mixing evenly, dry at 80°C for 3 days.

[0051] Implementation results: as shown in Figure 5, the composite phase change heat storage materials with different PEG molecular weights have the same crystal phase as the organic phase change material (PEG) therein; Figure 6 is the DSC of the composite phase change heat storage materials with different PEG molecular weights The curve shows that the phase transition temperature of the composite phase change thermal storage materials with different PEG molecular weights is obviously lower than that of the pure organic phase change material PEG with the corresponding molecular weight. As shown in Table 4, the phase transition temperature of the PEG / AC composite phase change heat storage mate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Phase change enthalpy | aaaaa | aaaaa |

| Phase change enthalpy | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com