Preparation method of metal organic framework based composite phase-change material

A technology of metal-organic framework and composite phase change materials, applied in heat exchange materials, chemical instruments and methods, reagents, etc., can solve the problems of poor adjustability and single selection of core materials, and achieve leakage prevention, simple process, The effect of mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] (1) Dissolve 2 mmol of chromium nitrate and 2 mmol of terephthalic acid in 15 mL of deionized water, add 5 mmol of sodium hydroxide, stir at room temperature for 30 minutes, and transfer them to the reactor. React for 12 h at ℃, filter and wash, dry in a vacuum drying oven at 60 ℃ for 24 h to obtain (Cr)MIL-101-NH 2 Metal organic framework material matrix.

[0029] (2) Dissolve 0.5 g of PEG2000 in 30 mL of absolute ethanol, dissolve it completely under stirring, and stir at 80 ℃ for 3 h to obtain a homogeneous solution. Add 0.125 g of (Cr)MIL-101-NH prepared above 2 Vacuum 4 h at 100 ℃ to completely open the pores of the substrate. Then the vacuumized (Cr)MIL-101-NH 2 Disperse in the prepared PEG2000 solution, stir at 80 ℃ for 6 h, then put it in a drying box, dry at 60 ℃ for 36 h, to obtain (Cr)MIL-101-NH 2 Load PEG composite phase change material.

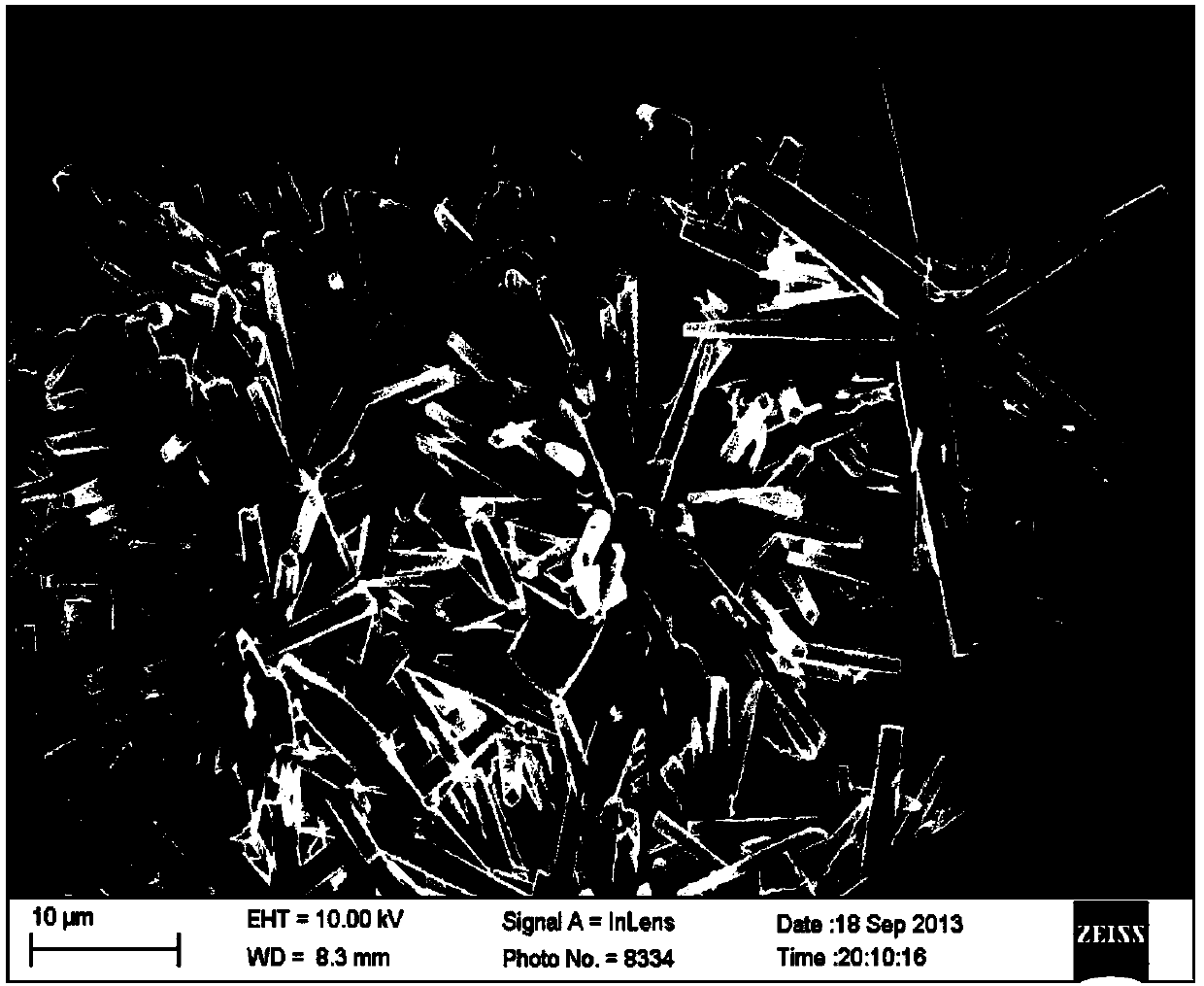

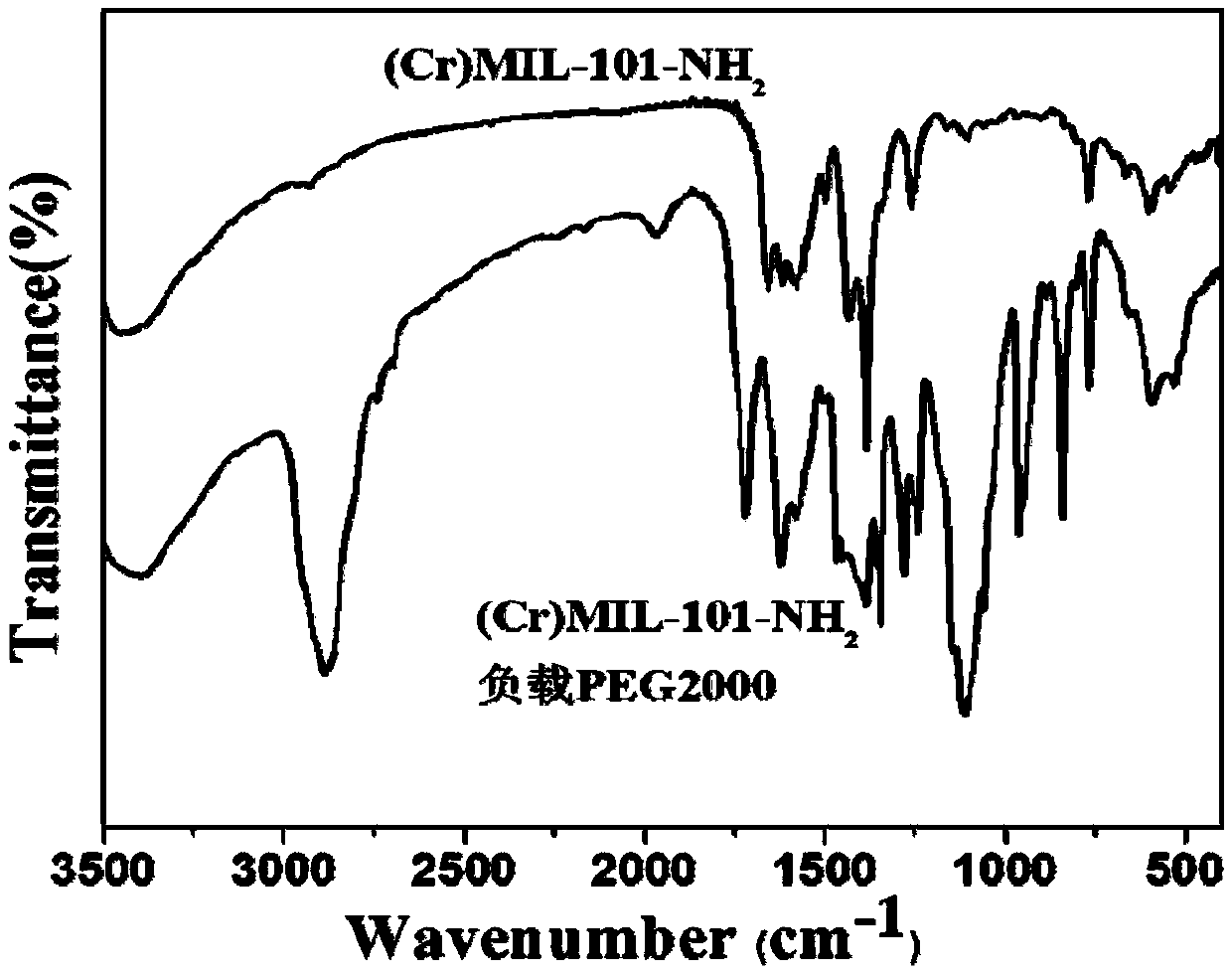

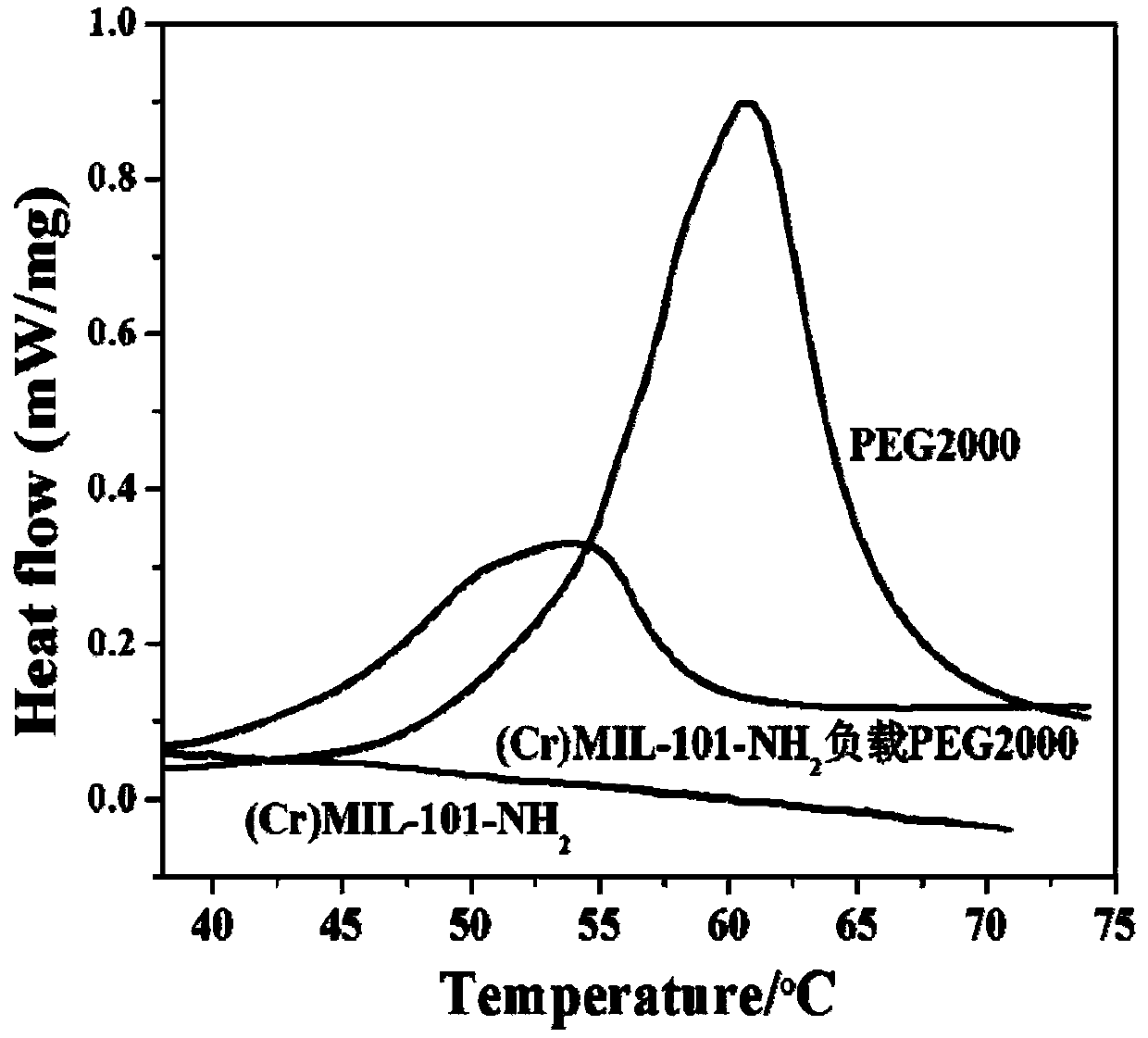

[0030] The obtained (Cr)MIL-101-NH 2 See the SEM picture of the PEG-loaded composite phase change material figure 1 , See th...

Embodiment 2

[0032] (1) Dissolve 1.7 mmol of zirconium chloride and 1.7 mmol of 2-aminoterephthalic acid in 25 mL of a mixed solution of N, N-dimethylformamide and deionized water (N, N-dimethyl The volume ratio of formamide and deionized water is 199:1), add 850 mmol of acetic acid, disperse ultrasonically at 60 ℃ for 30 min, then react at 120 ℃ for 24 h, centrifuge and wash, and dry at 60 ℃ in vacuum (Zr)UIO-66-NH is obtained after drying in the box for 24 h 2 Metal organic framework material matrix.

[0033] (2) Dissolve 8 g of lithium nitrate in 10 mL of deionized water, dissolve it completely under stirring conditions, and stir at 40 ℃ for 3 h to obtain a homogeneous solution. Put 3.5 g of (Zr) UIO-66-NH prepared above 2 Vacuum 4 h at 100 ℃ to completely open the pores of the substrate. Then the vacuumized (Cr)MIL-101-NH 2 Disperse in the prepared lithium nitrate solution, stir at 80 ℃ for 6 h, then put it in a drying box, and dry at 110 ℃ for 20 h. The resulting product was placed in ...

Embodiment 3

[0035] (1) Fully dissolve 1 mmol of chromium nitrate and 1 mmol of terephthalic acid in 4.8 mL of deionized water, add 4.5 mmol of hydrofluoric acid, and stir at room temperature for 30 minutes, then move them to the reaction kettle, The reaction was carried out at ℃ for 6 h, filtered and washed, and dried in a vacuum drying oven at 60 ℃ for 24 h to obtain (Cr)MIL-101 metal organic framework material matrix.

[0036] (2) Dissolve 0.4 g of calcium chloride hexahydrate in 15 mL of absolute ethanol, dissolve it completely under stirring, and stir at 80 ℃ for 3 h to obtain a homogeneous solution. 0.1 g of the (Cr)MIL-101 prepared above was evacuated at 100 ℃ for 4 h to completely open the pores of the substrate. Then disperse the vacuum-treated (Cr)MIL-101 in the prepared calcium chloride hexahydrate solution, stir at 80 ℃ for 6 h, then put it in a dry box, put it in the refrigerator at 5 ℃ 15 h, dried at 25 ℃ for 48 h to obtain (Cr)MIL-101-NH 2 Load calcium chloride hexahydrate co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com