Organic/inorganic composite phase-changing material capable of controlling smoke temperature of cigarette filter as well as preparation method and application of organic/inorganic composite phase-changing material

A technology of inorganic composite and phase change materials, applied in heat exchange materials, applications, e-liquid filter elements, etc., can solve the problems of poor smoke sensory quality and reduced filter retention efficiency, and achieve low cost, no need for special equipment, raw materials Easy to get effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

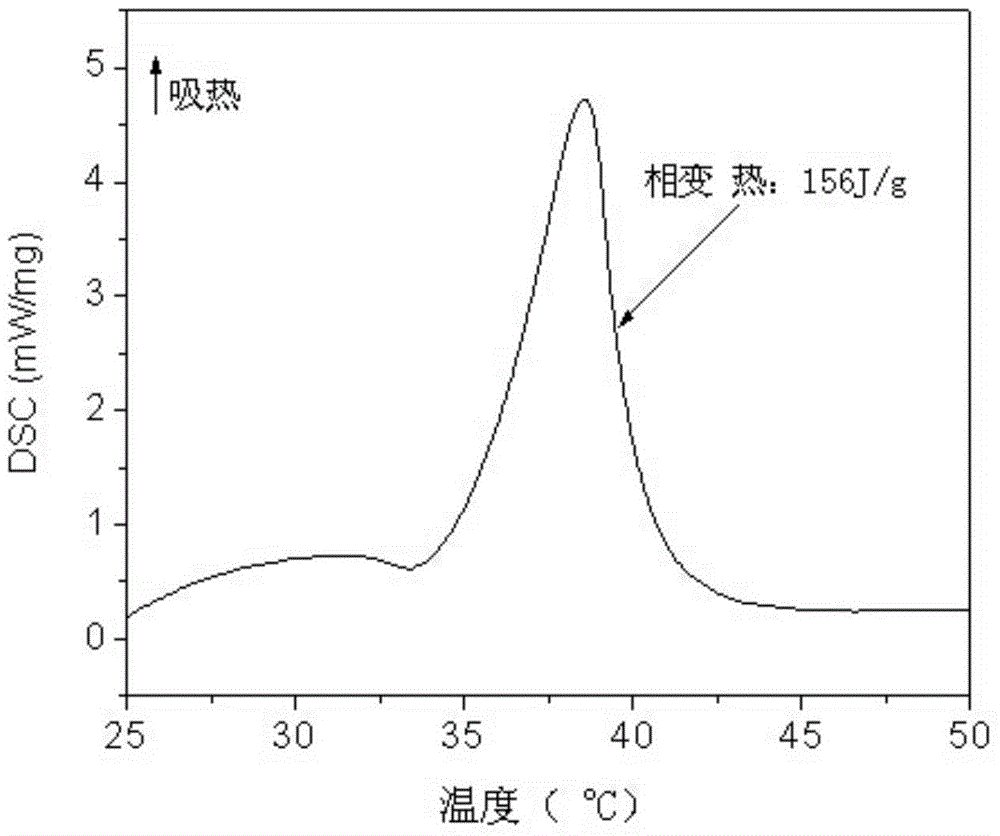

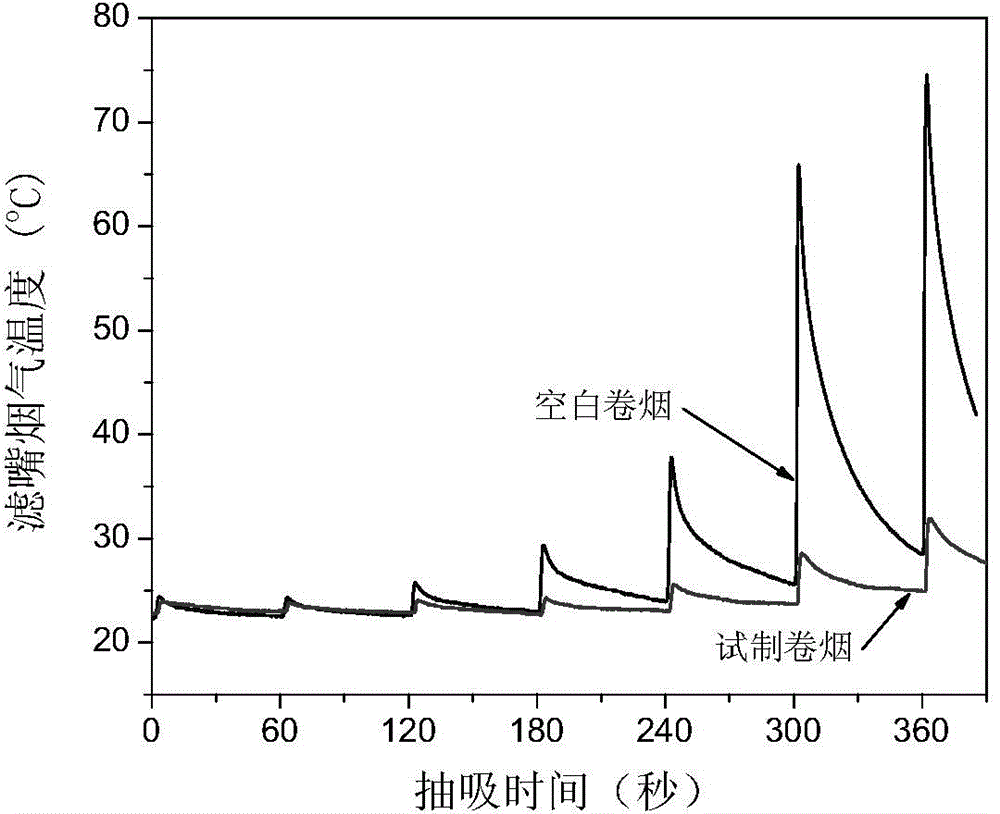

Embodiment 1

[0024] Weigh 18.8g hexacane (C 21 h 44 ) was heated to 50°C and melted, 1.2g of expanded graphite was added under stirring conditions for equal volume impregnation, and finally cooled and crystallized at a temperature not higher than 25°C for 2 hours to obtain 20.0g of organic-inorganic composite phase change materials, of which two The undecane loading was 94%. The phase change heat of this organic-inorganic composite phase change material is 156J / g, the phase change temperature is 32°C, and its DSC curve is as follows figure 1 shown. Weigh 30 mg / piece of composite phase-change material to prepare composite filter, and smoke in ISO mode on a single-hole smoking machine (puffing time is 2s, puffing interval is 58s, and the puffing capacity of each puff is 35mL). The gas phase temperature detector detects the filter flue gas temperature online. The test results show that, compared with the control sample, the composite filter with phase change material has a significant eff...

Embodiment 2

[0026] Weigh 16g hexacane (C 21 h 44 ) heated to 50°C to melt, add 4.0g of silica gel particles (30-60 mesh) under stirring conditions for equal volume impregnation, and finally cool and crystallize at a temperature not higher than 25°C for 2 hours to obtain 20.0g of organic-inorganic composite A phase change material, wherein the loading of hexacane is 80%. The phase change heat of the organic-inorganic composite phase change material is 128J / g, and the phase change temperature is 33°C. Weigh 40 mg / piece of composite phase-change material to prepare composite filter, and smoke in ISO mode on a single-hole smoking machine (puffing time is 2s, puffing interval is 58s, and the puffing capacity of each puff is 35mL). The gas phase temperature detector detects the filter flue gas temperature online. The test results show that, compared with the control sample, the composite filter with phase change material has a significant effect on reducing the temperature of the flue gas, e...

Embodiment 3

[0028] Weigh 18g eicosane (C 20 h 42 ) was heated to 50°C and melted, then 2.0g of expanded graphite was added under stirring conditions for equal volume impregnation, and finally cooled and crystallized at a temperature not higher than 25°C for 2 hours to obtain 20.0g of organic-inorganic composite phase change materials, of which two The loading of undecane was 90%. The phase change heat of the organic-inorganic composite phase change material is 136J / g, and the phase change temperature is 34°C. Weigh 40 mg / piece of composite phase-change material to prepare composite filter, and smoke in ISO mode on a single-hole smoking machine (puffing time is 2s, puffing interval is 58s, and the puffing capacity of each puff is 35mL). The gas phase temperature detector detects the filter flue gas temperature online. The test results show that, compared with the control sample, the composite filter with phase change material has a significant effect on reducing the temperature of the f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Heat of phase change | aaaaa | aaaaa |

| Heat of phase change | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com