Phase-change energy-storage building insulation structure

A technology for building thermal insulation and phase change energy storage, which is applied to building components, building structures, thermal insulation, etc. It can solve problems such as limiting the practical application of building walls, high prices of organic phase change materials, and affecting the sustainability of phase change materials. Achieve the effect of large latent heat of phase change, overcome easy phase separation and supercooling, and improve environmental comfort

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

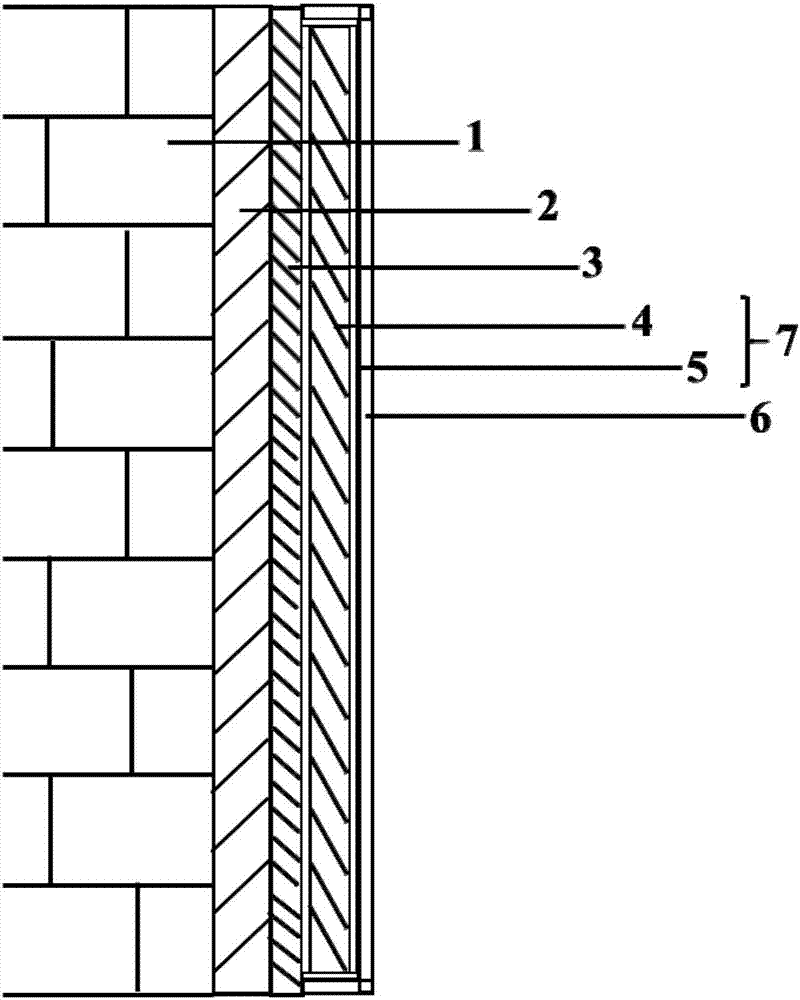

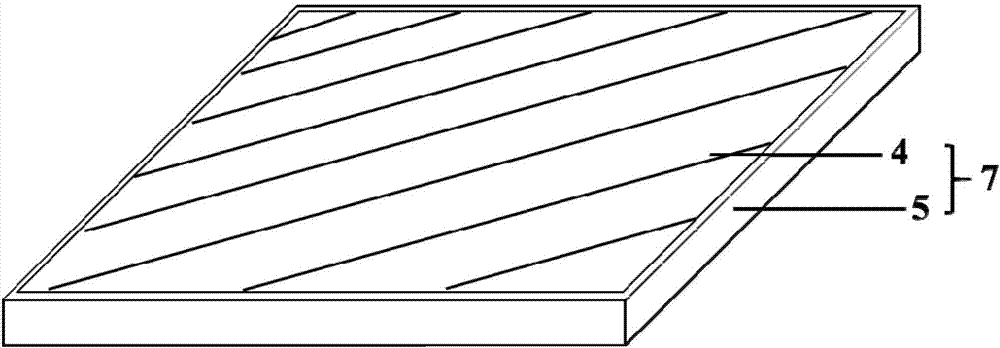

Embodiment 1

[0037] The wall base 1 is made of sand-lime brick and cement plaster layer. An EPS foam board with a thickness of 200mm is selected as the thermal insulation layer 2, and a plywood board with a thickness of 100mm is selected as the directional structure board 3. The inorganic hydrated magnesium chloride hexahydrate and magnesium nitrate hexahydrate are mixed and melted to obtain molten magnesium chloride hexahydrate / magnesium nitrate hexahydrate phase change material, and then compounded with the expanded graphite carrier to obtain a novel inorganic composite phase of expanded graphite-based magnesium chloride hexahydrate / magnesium nitrate hexahydrate The phase change temperature is 40℃, and the molten magnesium chloride hexahydrate / magnesium nitrate hexahydrate phase change material accounts for 95% of the composite phase change material. The composite phase change material is solid at room temperature. Choose a ring with a mass fraction of 5% The oxyacrylate resin is photocur...

Embodiment 2

[0041] Referring to Example 1, the difference is that the insulation board is a ceramic insulation board with a thickness of 100 mm. The test experiment shows that the temperature fluctuation in the experimental room is reduced by 16°C, and the maximum temperature is delayed by 80 minutes, and the temperature fluctuation in the reference room is reduced by 8°C, and the maximum temperature is delayed by 10 minutes, indicating that there is a fixed phase change energy storage The wall structure of the insulation board has more excellent heat storage capacity, can significantly improve the thermal inertia of the wall, delay the appearance of the indoor peak temperature, and fully reduce the range of indoor temperature fluctuations. The thermal insulation effect of this laboratory room is slightly worse than that of the laboratory room of Example 1, because the thermal conductivity of the ceramic thermal insulation board is higher than that of the EPS foam board, and the thickness o...

Embodiment 3

[0043] Referring to Example 1, the difference is that the thermal insulation board is an XPS extruded board with a thickness of 50 mm.

[0044] The test experiment with Example 1 shows that the temperature fluctuation in the experimental room is reduced by 17°C, the maximum temperature is delayed by 85 minutes, and the temperature fluctuation in the reference room is reduced by 9°C, and the maximum temperature is delayed by 15 minutes, indicating that the phase change energy storage is included The wall structure of the insulation board has more excellent heat storage capacity, can significantly improve the thermal inertia of the wall, delay the appearance of the indoor peak temperature, and fully reduce the range of indoor temperature fluctuations. The thermal insulation effect of this laboratory room is similar to that of Example 1, because the thermal conductivity of the XPS extruded board thermal insulation board is lower than that of the EPS foam board.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com