Device and method for measuring phase change latent heat of composite phase change energy storage material

A technology of phase change latent heat and energy storage materials, applied in the investigation stage/state change, etc., can solve the problems of poor representation, small sampling amount, and inability to reflect the composition of composite phase change materials, etc., and achieve good thermal properties and reduce errors.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The specific technical solutions are:

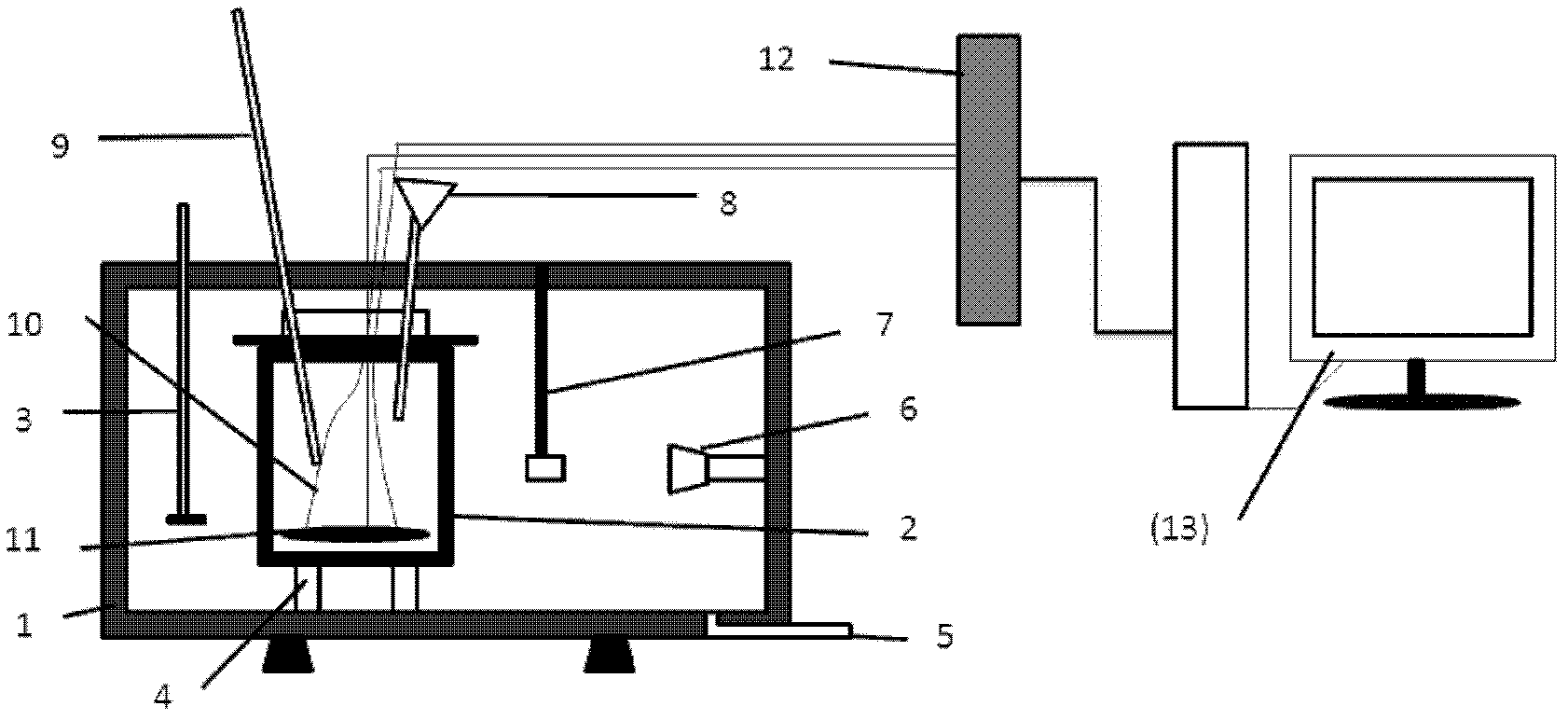

[0023] 1. Test equipment

[0024] The main components include: test cylinder, heating device, measuring device, data acquisition device and computer.

[0025] The test cylinder is composed of a constant temperature water tank 1 and a test inner cylinder 2. The inner and outer layers of the constant temperature water tank 1 have heat insulation layers, and an aqueous solution agitator 3, an inlet and outlet pipe 5, a heating pipe 6 and a circulating water pump 7 are installed in the water tank. The test inner cylinder 2 is placed on the test inner cylinder support 4, and the mouth of the cylinder is well sealed to prevent water leakage; three holes are distributed on the cylinder cover for installing the feeding funnel 8, the thermometer 9 and the temperature measuring thermocouple 10. The inner lining of the cylinder cover and the cylinder wall is a cork or foam plastic insulation layer and a corrosion-resistant plastic layer. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| phase transition temperature | aaaaa | aaaaa |

| phase transition enthalpy | aaaaa | aaaaa |

| phase transition enthalpy | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com