Preparation method of nano particle-doped phase change microcapsule

A technology of phase change microcapsules and nanoparticles, which can be used in microcapsule preparations, microsphere preparation, chemical instruments and methods, etc., and can solve the problems of single function of phase change materials.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

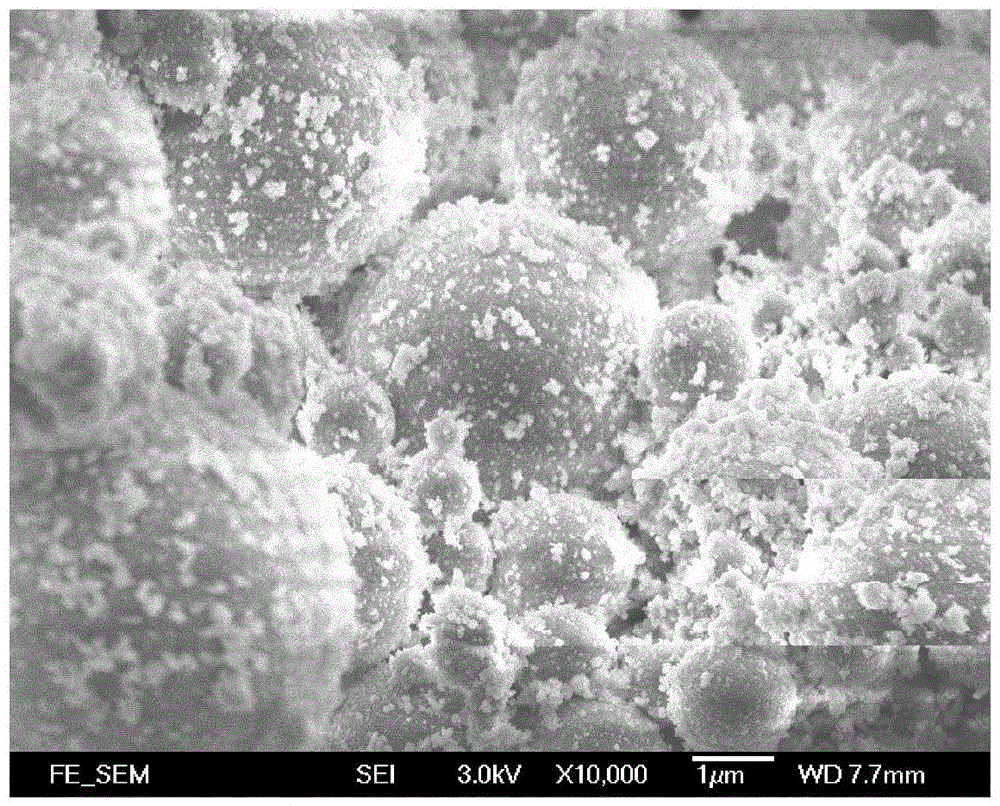

Embodiment 1

[0035] Step 1, nanomaterial surface treatment:

[0036] After diluting 5.2g of dodecyltrimethylsiloxane with 100mL ethanol solvent, adjust its pH value to 4 with 10% acetic acid solution, and stir at room temperature for 10min to obtain a surface treatment agent solution; take 6mL surface treatment agent solution Add it to 6g of P25 nano-titanium dioxide, stir and react for 20 minutes, heat up to 50°C, keep warm for 20 minutes, filter the product, dry it in an oven at 60°C, cool and grind it to get the treated P25 nano-titanium dioxide powder, spare;

[0037] Step 2, preparation of capsule wall material:

[0038] Mix 5.62g of melamine and 5.06mL of formaldehyde with a mass concentration of 37%, stir and react at 70°C for 30min to become a clear liquid, lower it to room temperature to obtain a prepolymer, and set aside;

[0039] Step 3, nanomaterial doping:

[0040] Place 30g of n-hexadecane in a water bath at 50°C, heat and stir to melt it, take 3g of the sodium salt of pol...

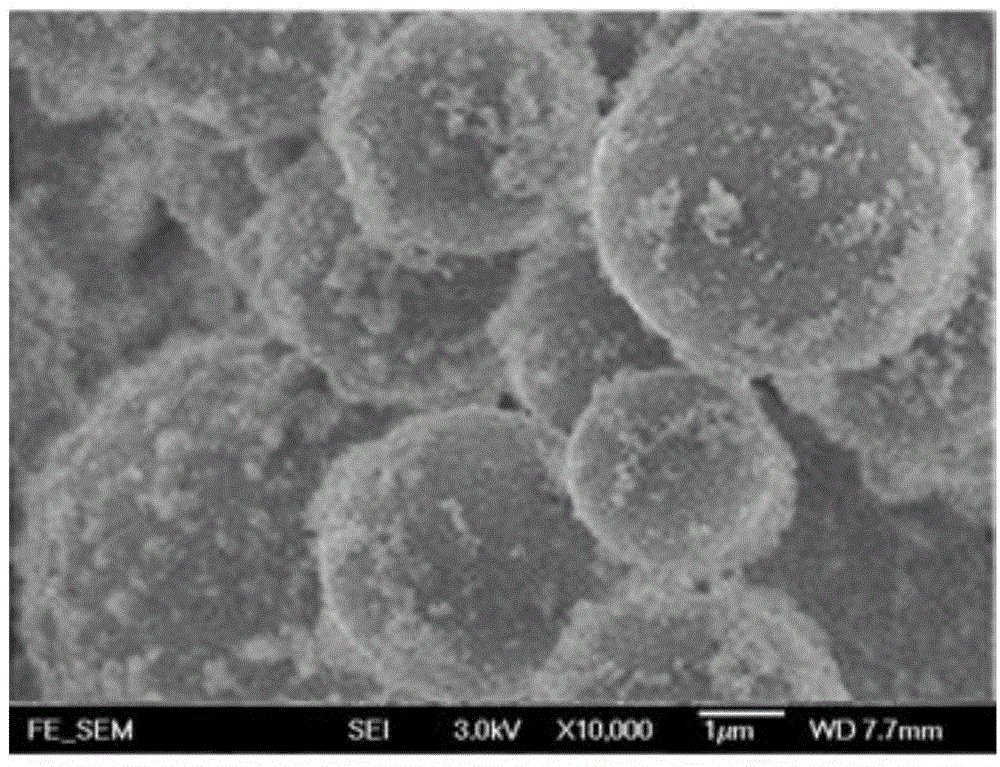

Embodiment 2

[0047] Step 1, nanomaterial surface treatment:

[0048] After diluting 12g of dodecyltrimethylsiloxane with 100mL of ethanol solvent, adjust its pH value to 4.5 with 10% acetic acid solution, and stir at room temperature for 10min to obtain a surface treatment agent solution; take 30mL of the surface treatment agent solution and add Add 6g of P25 nano-titanium dioxide, stir and react for 20 minutes, heat up to 55°C, keep warm for 20 minutes, filter the product, dry it in an oven at 63°C, cool and grind to obtain the treated P25 nano-titanium dioxide powder, set aside ;

[0049] Step 2, preparation of capsule wall material:

[0050] Mix 8.12g of melamine and 10.46mL of formaldehyde with a mass concentration of 37%, stir and react at 70°C for 30min to become a clear liquid, lower it to room temperature to obtain a prepolymer, and set aside;

[0051] Step 3, nanomaterial doping:

[0052] Place 30g of n-hexadecane in a water bath at 50°C, heat and stir to melt it, take 5g of sodi...

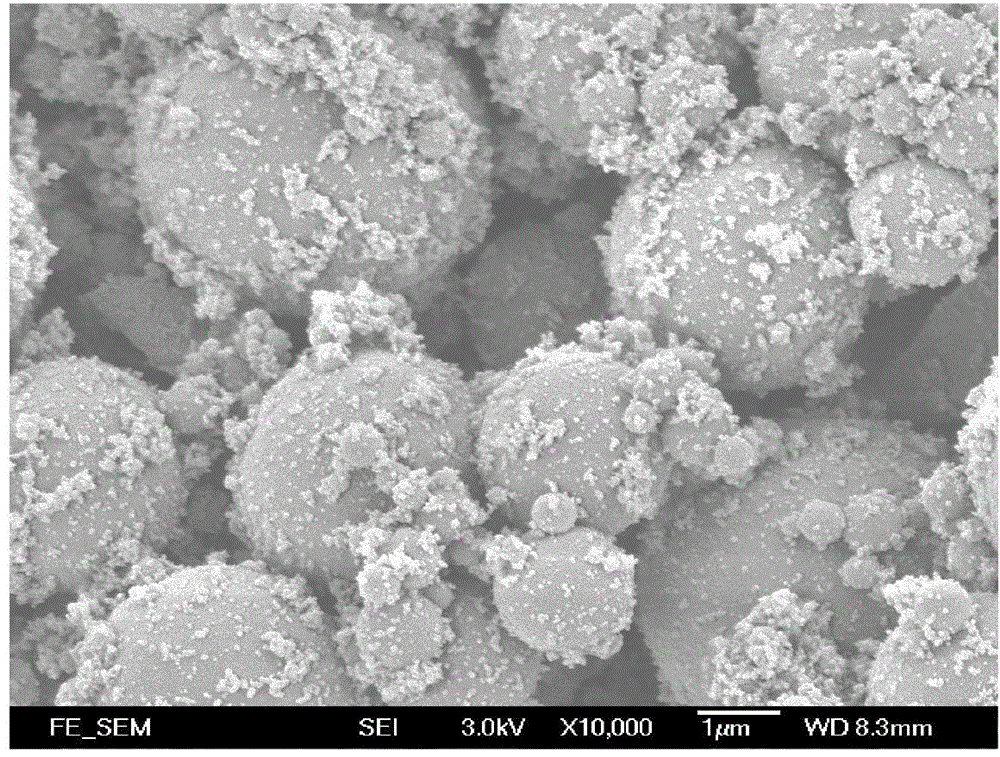

Embodiment 3

[0059] Step 1, nanomaterial surface treatment:

[0060] Dilute 25g of octyltrimethoxysilane with 100mL of methanol solvent, adjust its pH value to 5 with 10% acetic acid solution, and stir at room temperature for 10min to obtain a surface treatment agent solution; take 60mL of the surface treatment agent solution and add it to 6g of P25 nano In titanium dioxide, after stirring and reacting for 20 minutes, the temperature was raised to 60° C., and the heat preservation reaction was carried out for 20 minutes. After the product was suction-filtered, it was placed in an oven at 65° C. for drying, and after cooling and grinding, the processed P25 nano-titanium dioxide powder was obtained, which was set aside;

[0061] Step 2, preparation of capsule wall material:

[0062] Mix 2.35g of melamine and 7.6mL of formaldehyde with a mass concentration of 37%, stir and react at 70°C for 50min to become a clear liquid, lower it to room temperature to obtain a prepolymer, and set aside;

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com