Preparation method of modified aerosil-based composite phase-change material

A technology of composite phase change materials and silica, applied in chemical instruments and methods, heat exchange materials, colloid chemistry, etc., can solve problems such as limited practical application and high cost, and achieve improved load capacity, service life, and cycle time Short, simple process effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

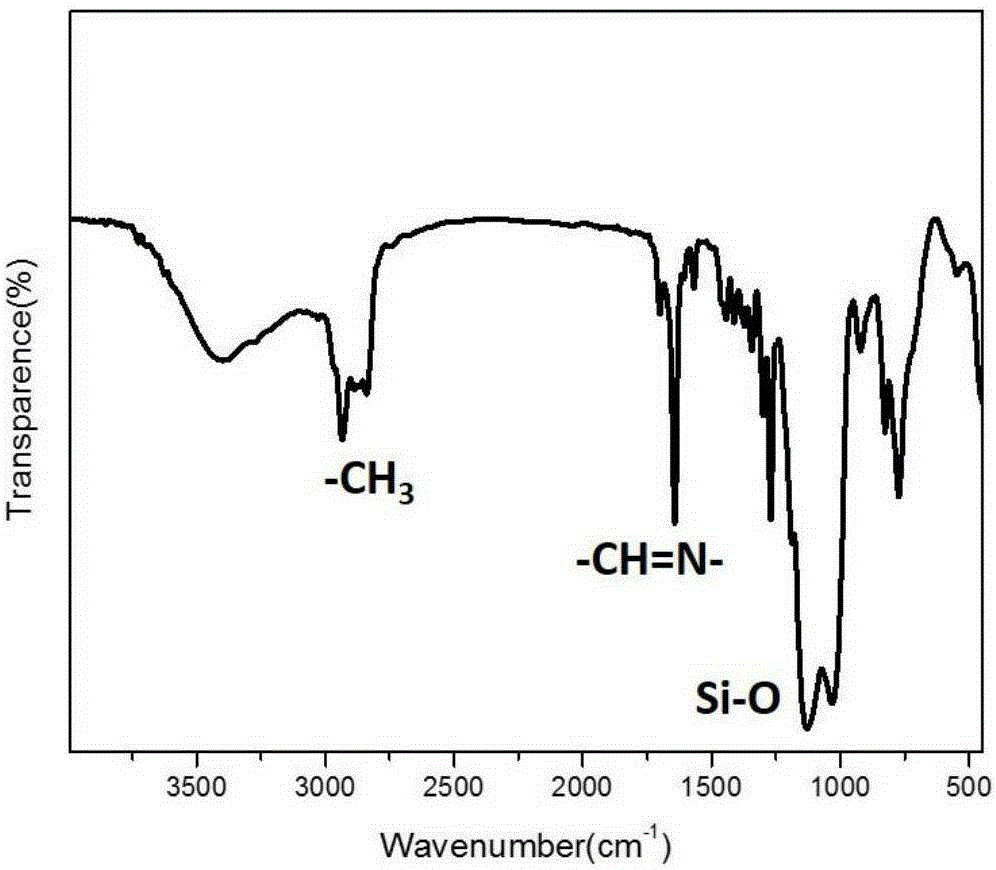

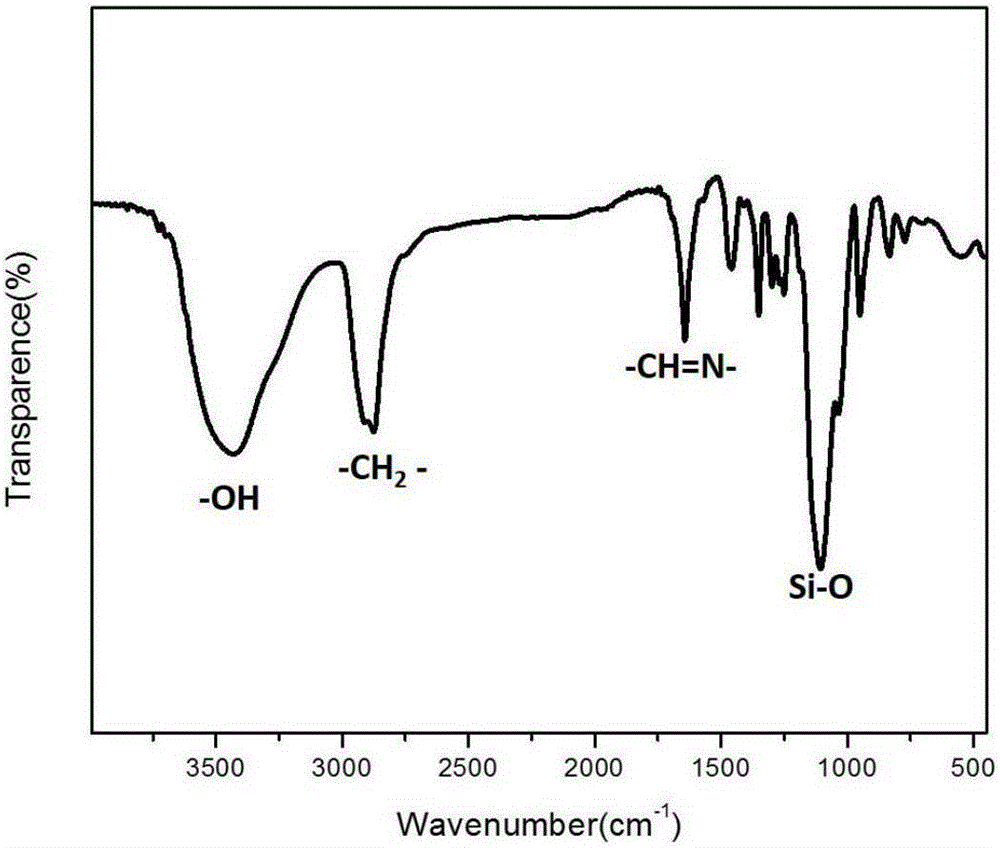

[0027] 3-aminopropyltrimethoxysilane, terephthalaldehyde, 0.2molL -1 The hydrochloric acid solution and absolute ethanol were mixed at a molar ratio of 1:0.33:20:0.4, stirred at room temperature for 20 minutes to mix evenly, and the above solution was sealed and stored at 40°C for 12 hours to form a gel. Then, the excess ethanol / water mixture was removed from the obtained gel, soaked in an appropriate amount of absolute ethanol, and kept at 40° C. for 24 hours to remove residual chemical substances. Repeat this 2 times. Then, the temperature was raised to 80° C. under a program with a heating rate of 1° C. / min, and the modified nanoporous silica airgel was obtained after drying under normal pressure for 36 hours.

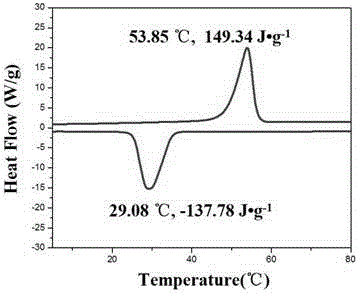

[0028] Dissolve 0.5 g of PEG2000 in 30 mL of absolute ethanol, dissolve it completely under stirring, and stir at 80° C. for 3 h to obtain a homogeneous solution. 0.125 g of the modified nanoporous silica airgel was vacuumed at 100° C. for 4 hours to completely op...

Embodiment 2

[0031] 3-aminopropyldimethylethoxysilane, 4,4'-biphenyldicarbaldehyde, 0.1molL -1 Nitric acid and anhydrous methanol were mixed at a molar ratio of 1:0.2:30:0.06, stirred at room temperature for 10 minutes to mix evenly, and the above solution was sealed and stored at 80°C for 6 hours to form a gel. Then, the excess ethanol / water mixture was removed from the obtained gel, soaked in an appropriate amount of absolute ethanol, and kept at 20° C. for 10 h to remove residual chemical substances. Repeat this 1 time. Then, the temperature was raised to 120° C. under a program with a heating rate of 2.5° C. / min, and the modified nanoporous silica airgel was obtained after drying at normal pressure for 24 hours.

[0032]Dissolve 0.5 g of stearic acid in 30 mL of absolute ethanol, dissolve it completely under stirring, and stir at 10° C. for 1 h to obtain a uniform solution. 0.125 g of the modified nanoporous silica airgel was vacuumed at 40° C. for 2 hours to completely open the pore...

Embodiment 3

[0034] 3-aminopropyltriethoxysilane, 2 amino-terephthalaldehyde, 0.5molL -1 Formic acid and n-hexane were mixed at a molar ratio of 1:1:15:0.6, stirred at room temperature for 30 minutes to mix evenly, and the above solution was sealed and stored at 20°C for 36 hours to form a gel. Then, the excess ethanol / water mixture was removed from the obtained gel, soaked in an appropriate amount of absolute ethanol, and kept at 70° C. for 24 hours to remove residual chemical substances. Repeat this 4 times. Then, the temperature was raised to 60° C. under a program with a heating rate of 5° C. / min, and the modified nanoporous silica airgel was obtained after drying at normal pressure for 120 hours.

[0035] Dissolve 0.5 g of paraffin in 30 mL of absolute ethanol, dissolve it completely under stirring, and stir at 120° C. for 5 h to obtain a homogeneous solution. Vacuumize 0.125g of modified silica airgel at 200°C for 10h to completely open the pores of the matrix. Then disperse the v...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com