Method for preparing polyethylene glycol and epoxy resin formed composite phase-change materials

A composite phase-change material and epoxy resin technology, applied in the direction of heat exchange materials, chemical instruments and methods, etc., can solve the problems of influence and difficulty in uniformly dispersing the thermal properties of polyethylene glycol, and achieve high stability and energy storage Good effect, good setting performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] At room temperature, in a 1.5L Erlenmeyer flask, add 200g of grade E51 epoxy resin liquid with an epoxy value of 0.6, and slowly add polyethylene glycol (PEG4000 / PEG8000=1 / 1) powder under vigorous stirring with a CNC mixer 900g, after it is completely dissolved and evenly dispersed with EP, add the mixed solution of 40% D230 curing agent and 10% DMP-30 accelerator respectively accounting for the amount of EP, and keep stirring until all are mixed evenly. Degas the reaction mixture under vacuum. When there are no more bubbles in the reaction liquid, pour it into a preheated mold coated with a release agent, transfer the mold to a 60°C oven for solidification and molding for 48 hours, and cool Demoulding at room temperature to obtain a fixed composite phase change material.

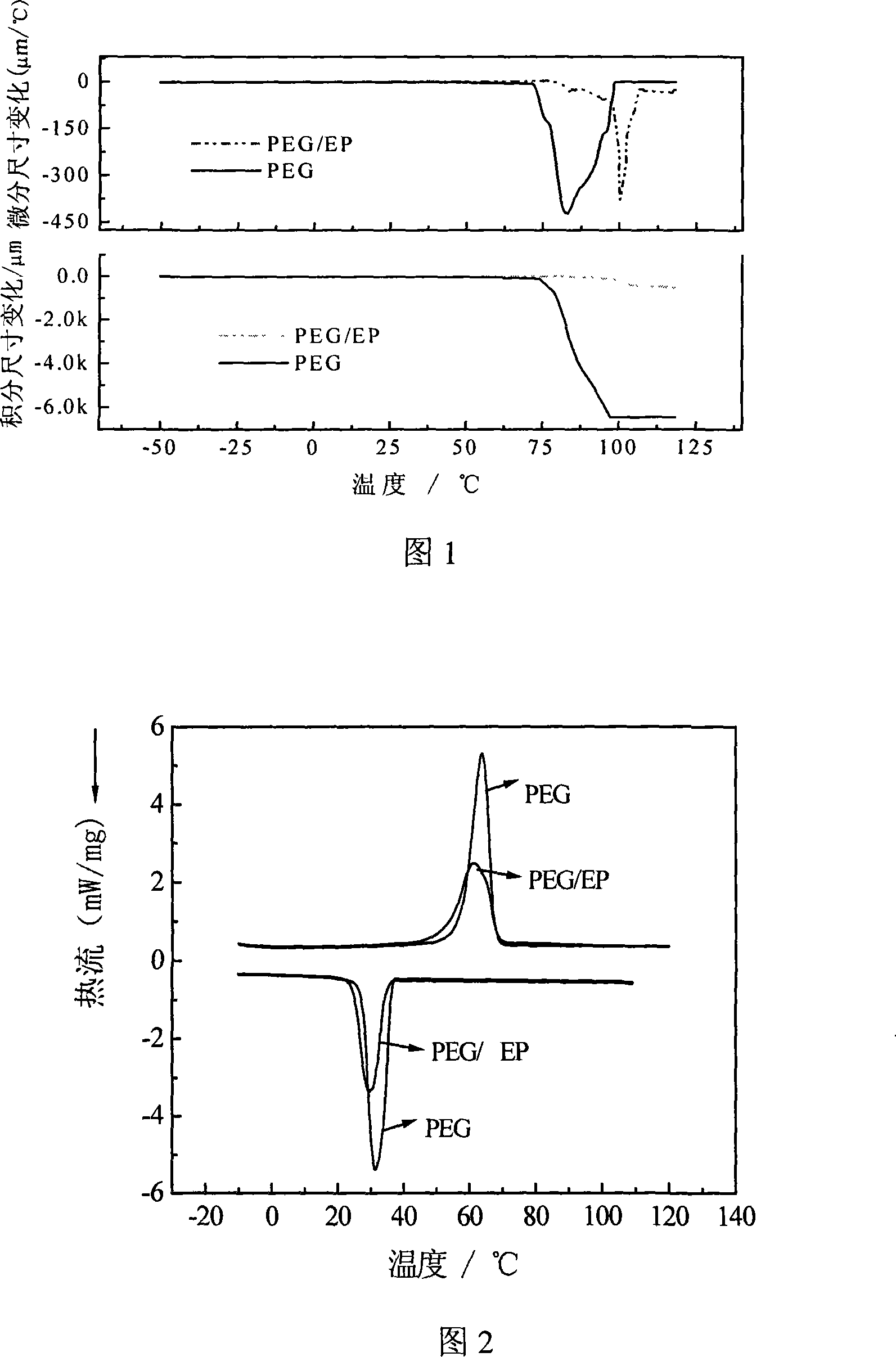

[0023] The thermomechanical analysis of the above composite phase change material is shown in Figure 1: For the polyethylene glycol sample, phase transition occurs during the thermal melting process,...

Embodiment 2

[0029] At room temperature, in a 1L Erlenmeyer flask, add 100g of E44 epoxy resin liquid with an epoxy value of 0.3, and slowly add 100g of polyethylene glycol (PEG4000 / PEG10000=1 / 1) powder under vigorous stirring by a CNC mixer , after it is completely dissolved and evenly dispersed with EP, add the mixed solution of 8% D230 curing agent and 1% DMP-30 accelerator respectively accounting for the amount of EP, and keep stirring until all are mixed evenly. Degas the reaction mixture under vacuum. When there are no more air bubbles in the reaction liquid, pour it into a preheated mold coated with a release agent, transfer the mold to a 60°C oven for solidification and molding for 24 hours, and cool Demoulding at room temperature to obtain a fixed composite phase change material.

Embodiment 3

[0031]At room temperature, in a 1.5L Erlenmeyer flask, add 100g of epoxy resin liquid with grade E31 and an epoxy value of 0.5, and slowly add polyethylene glycol (PEG4000 / PEG8000=1 / 1) powder under vigorous stirring by a CNC mixer 500g, after it is completely dissolved and evenly dispersed with EP, add the mixed solution of 30% D230 curing agent and 5% DMP-30 accelerator respectively accounting for the amount of EP, and keep stirring until all are mixed evenly. Degas the reaction mixture under vacuum. When there are no more bubbles in the reaction liquid, pour it into a preheated mold coated with a release agent, transfer the mold to a 60°C oven for solidification and molding for 36 hours, and cool Demoulding at room temperature to obtain a fixed composite phase change material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting temperature | aaaaa | aaaaa |

| Phase transition temperature | aaaaa | aaaaa |

| Melting enthalpy | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com