Method for measuring contents of silicon, magnesium and aluminum in coal combustion-supporting agent

A technology of coal combustion enhancer and determination method, which is applied in the field of chemical detection, can solve the problems of difficult content, etc., and achieve the effects of convenient operation, shortened detection cycle, and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

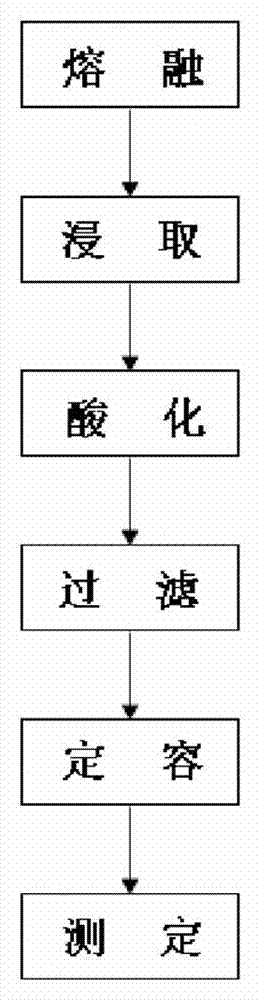

Method used

Image

Examples

Embodiment 1

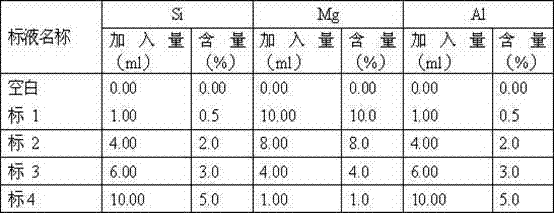

[0044] Prepare the following standard solutions as usual:

[0045] 1. Silicon standard solution:

[0046] 1A. Calcinate silicon dioxide with a purity of more than 99.9% at 1000°C for 1 hour, place it in a desiccator and cool it to room temperature;

[0047] 1B, according to the amount of 5g / g sample, place 1.0696g of silicon dioxide in step 3A in a platinum crucible containing 3g of mixed flux of anhydrous sodium carbonate and boric acid that is ground and mixed, and then cover with 2g of ground Fine and uniform mixed flux of anhydrous sodium carbonate and boric acid, heating the crucible at a low temperature of 400°C, and then heating at a high temperature of 950°C for 40 minutes, cooling, wherein the mixed flux is the following mass ratio: anhydrous sodium carbonate:boric acid=2 :1;

[0048] 1C. Put the platinum crucible in step 3B into a beaker filled with 100mL of cold water to leach the frit until completely dissolved, then take out the crucible, and cool the solution t...

Embodiment 2

[0077] 1. Preparation of silicon, magnesium and aluminum sample liquids in the catalytic combustion combustion aid of coal for blast furnace injection:

[0078] 1A. According to the amount of 20g / g sample, put 0.1000g of the sample to be tested in a nickel crucible with 2g of anhydrous sodium carbonate and sodium peroxide mixed flux mixed in advance, and mix well, wherein the mixed flux is as follows Mass ratio: anhydrous sodium carbonate: sodium peroxide=1:4;

[0079] 1B. Melt the nickel crucible in step 1A at 700°C for 5 minutes, take it out, and cool it down:

[0080] 1C, leaching the nickel crucible in step 1B with warm water, washing out the crucible to obtain a mixed solution;

[0081] 1D. In the mixed solution obtained in step 1C, use 5 mL / g of mixed flux, add 10 mL of hydrochloric acid to acidify, heat to dissolve salts, cool, and filter to obtain a solution;

[0082] 1E. According to the amount of 25L / g sample, add distilled water to the solution obtained in step 1D...

Embodiment 3

[0087] 1. Preparation of silicon, magnesium and aluminum sample liquids in the catalytic combustion combustion aid of coal for blast furnace injection:

[0088] 1A. According to the amount of 25g / g sample, place 0.1000g of the sample to be tested in a nickel crucible with 2.5g of mixed flux of anhydrous sodium carbonate and sodium peroxide added in advance, and mix well, wherein the mixed flux is Following mass ratio: anhydrous sodium carbonate: sodium peroxide=1:4;

[0089] 1B. Melt the nickel crucible in step 1A at 720°C for 6 minutes, take it out, and cool it down:

[0090] 1C, leaching the nickel crucible in step 1B with warm water, washing out the crucible to obtain a mixed solution;

[0091] 1D. In the mixed solution obtained in step 1C, use 3 mL / g of mixed flux, add 8 mL of hydrochloric acid to acidify, heat to dissolve salts, cool and filter to obtain a solution;

[0092] 1E. According to the amount of 25L / g sample, add distilled water to the solution obtained in ste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com