Automatic cutting production line for ceramsite blocks

An automatic cutting and production line technology, applied in the direction of stone processing tools, work accessories, manufacturing tools, etc., can solve the problems of poor cutting performance, harsh working environment, high labor intensity, etc., achieve a good working environment, simplify the cutting process, and reduce cutting friction small force effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0071] The present case will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

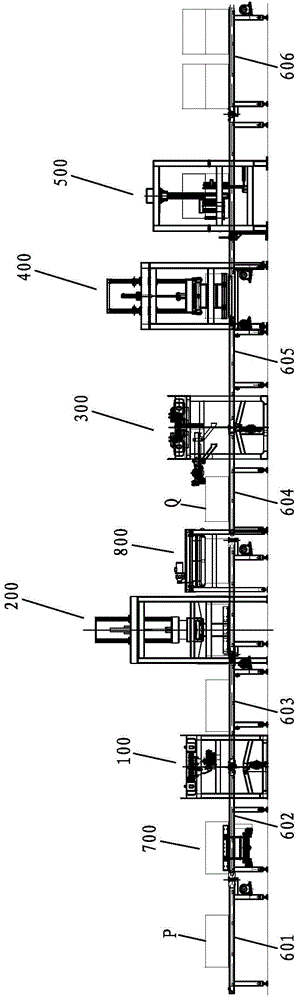

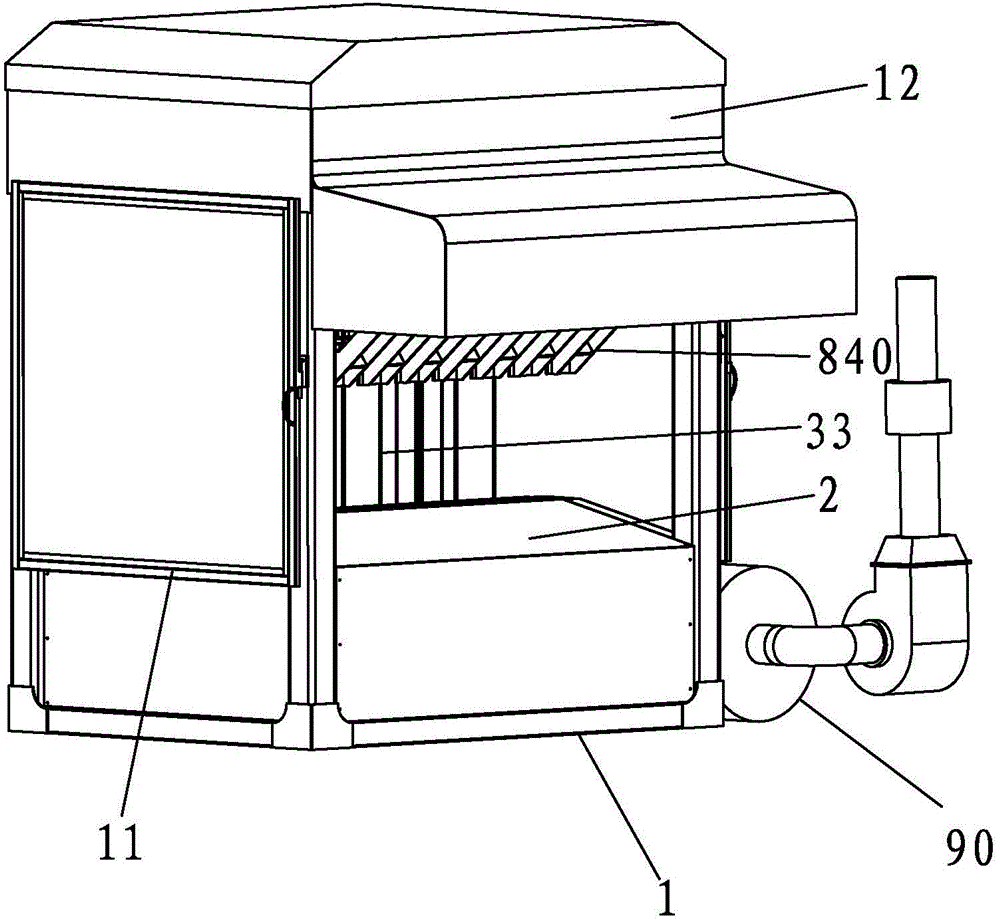

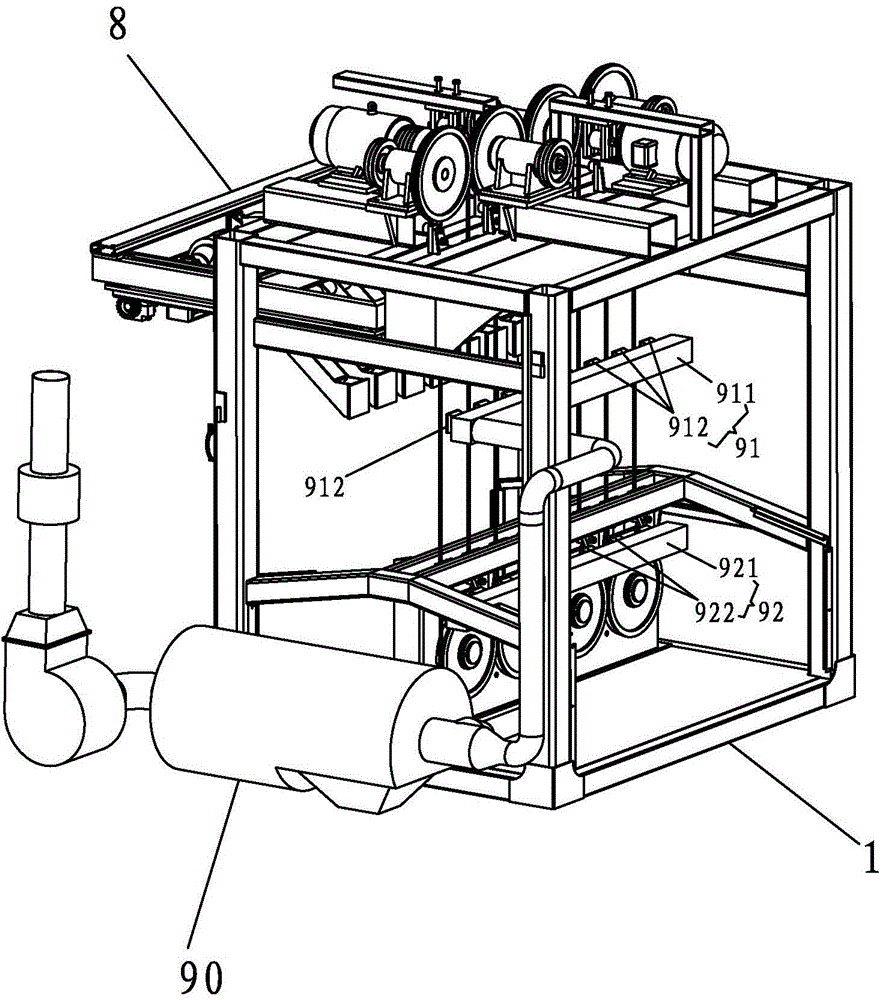

[0072] This case involves an automatic cutting production line for ceramsite blocks, such as figure 1 As shown, it includes a chain plate conveying line and a first cutting machine 100 , a rotary palletizer 200 , a second cutting machine 300 , a single clip palletizing machine 400 and a wrapping packer 500 arranged sequentially along the chain plate conveying line. The structure of the first cutting machine 100 and the second cutting machine 300 is the same, as Figure 2-7 As shown, it mainly includes a frame 1 , an upper saw band wheel set 31 , a lower saw band wheel set 32 and several saw bands 33 .

[0073] like Figure 3-7 As shown, the upper saw band wheel set 31 is provided with a plurality of saw band wheels, which are arranged horizontally in a row at the upper end of the frame 1. Preferably, the upper saw band wheel set 31 is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com