Taping machine for decorative plate and insertion plate on automobile door plate

A decorative panel and edge wrapping machine technology, which is applied in the field of auto parts processing machinery, can solve the problems of unsatisfactory mass production, difficult to guarantee the quality of finished products, defective products and high scrap rate, so as to reduce physical injuries, improve product quality, The effect of avoiding defective and waste products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

[0026] It should be noted that, unless otherwise clearly stipulated and limited, the terms "first", "second" and the like do not represent sequential installation, nor do they represent the importance of the described parts.

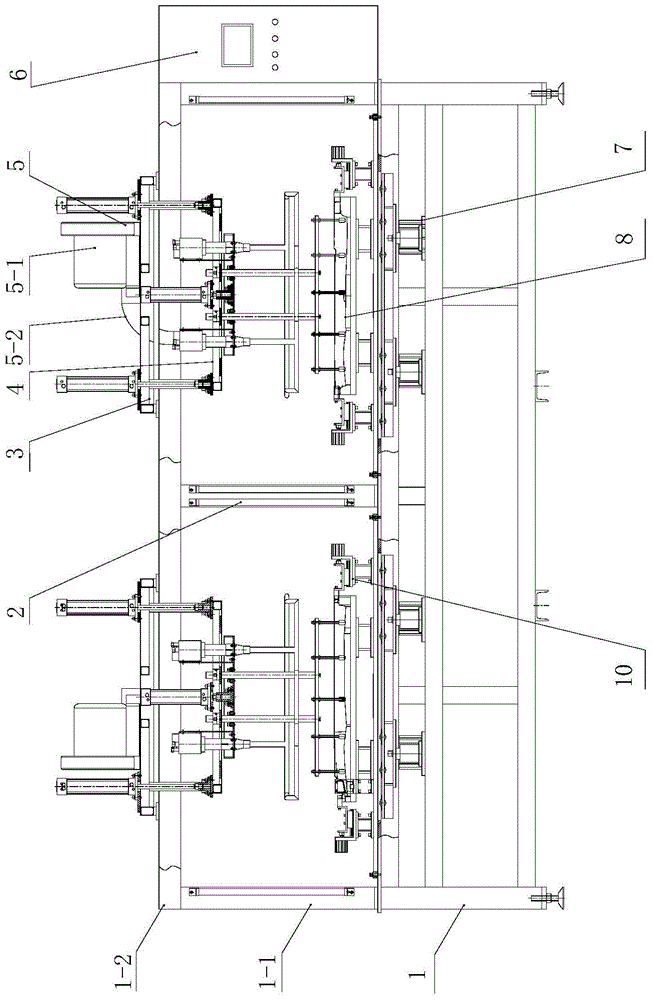

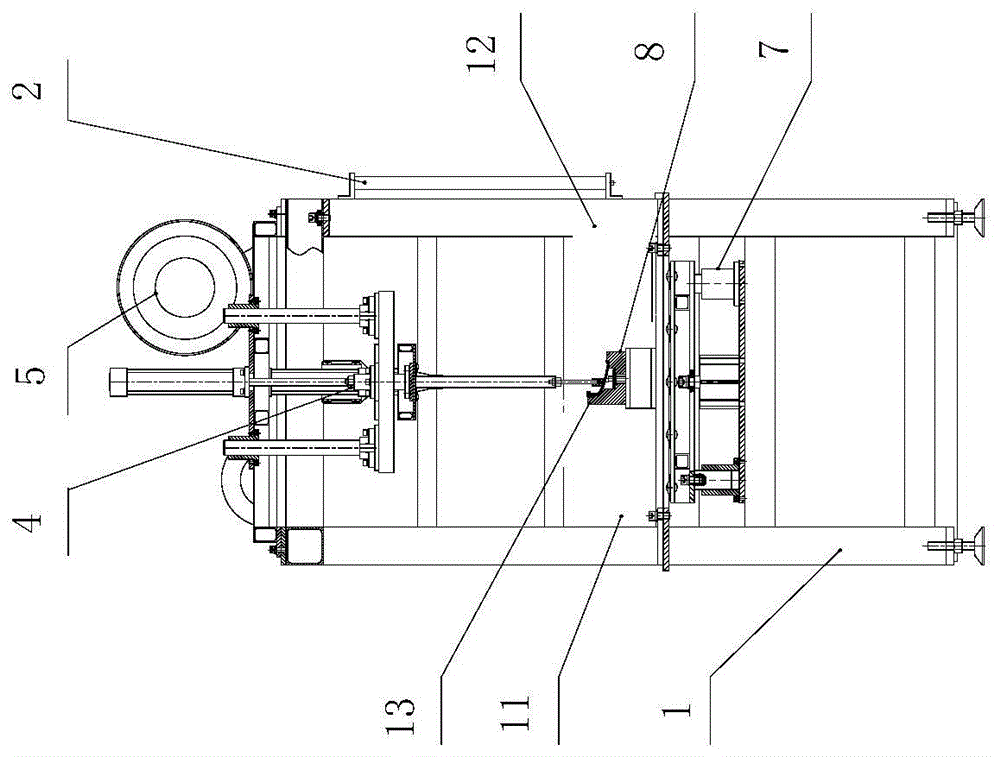

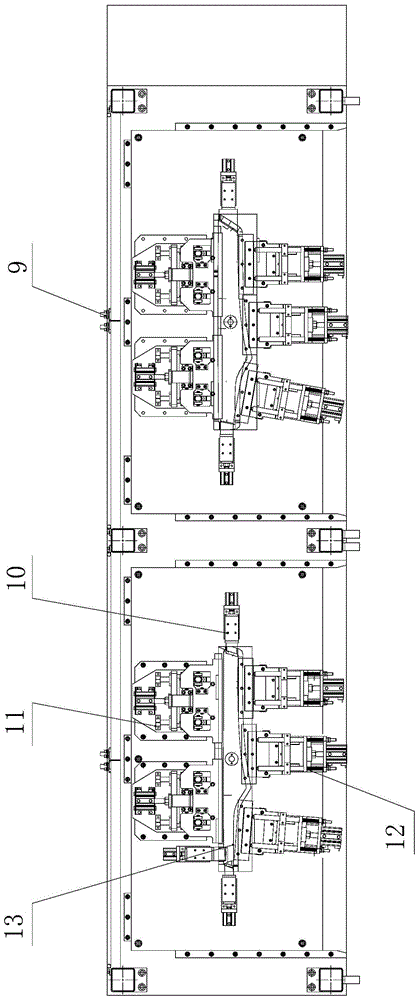

[0027] see Figure 1-Figure 9 , a decorative panel and an inlay panel hemming machine on an automobile door panel, comprising a frame 1 composed of a base 1-3, a crossbeam 1-1 and a support 1-2, the base of the frame is equipped with a The positioning membrane 8 of the decorative plate, the hemming assembly arranged on the periphery of the positioning membrane, the bottom of the positioning membrane is equipped with a mold changing system 7 . Positioning and pressing device 3, heating device 4 and air supply system 5 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com