Board brushing system capable of automatically removing dust

A technology of automatic dust removal and brush, which is applied in the direction of dust removal, cleaning method using tools, and device for coating liquid on the surface, etc., which can solve the problems that regular cleaning cannot remove dust, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

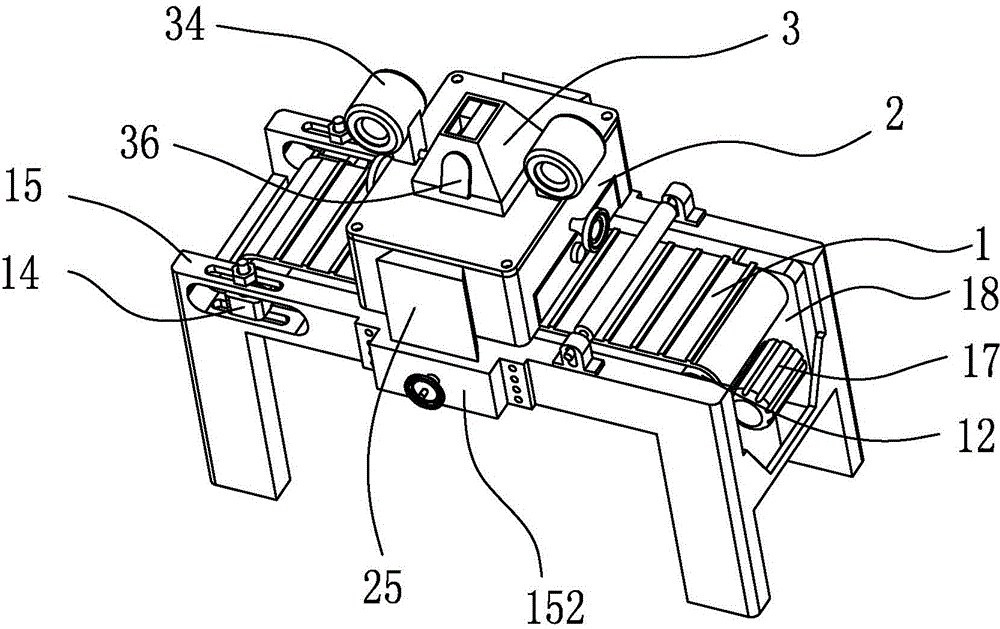

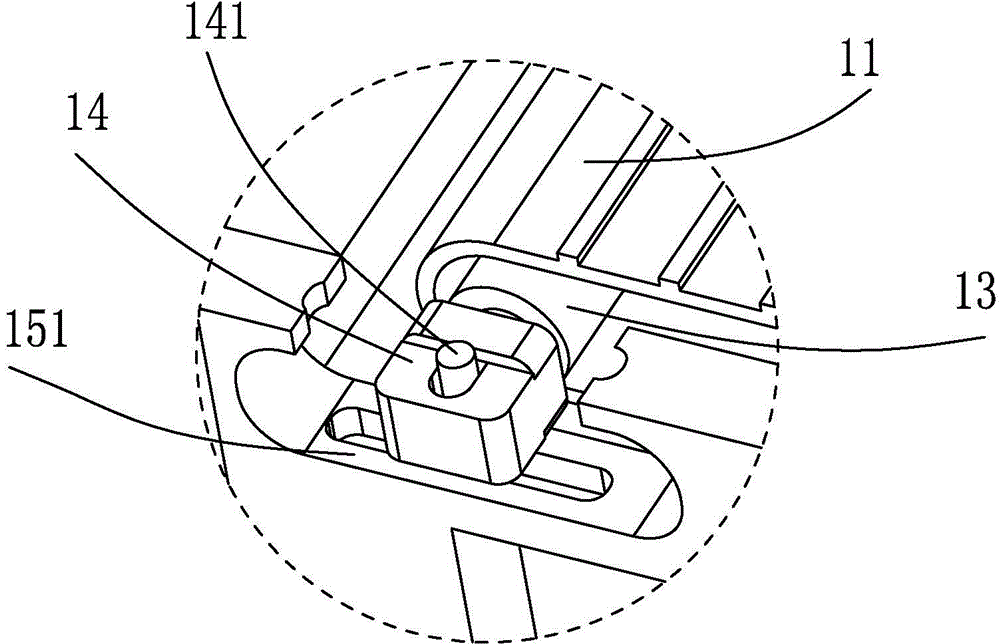

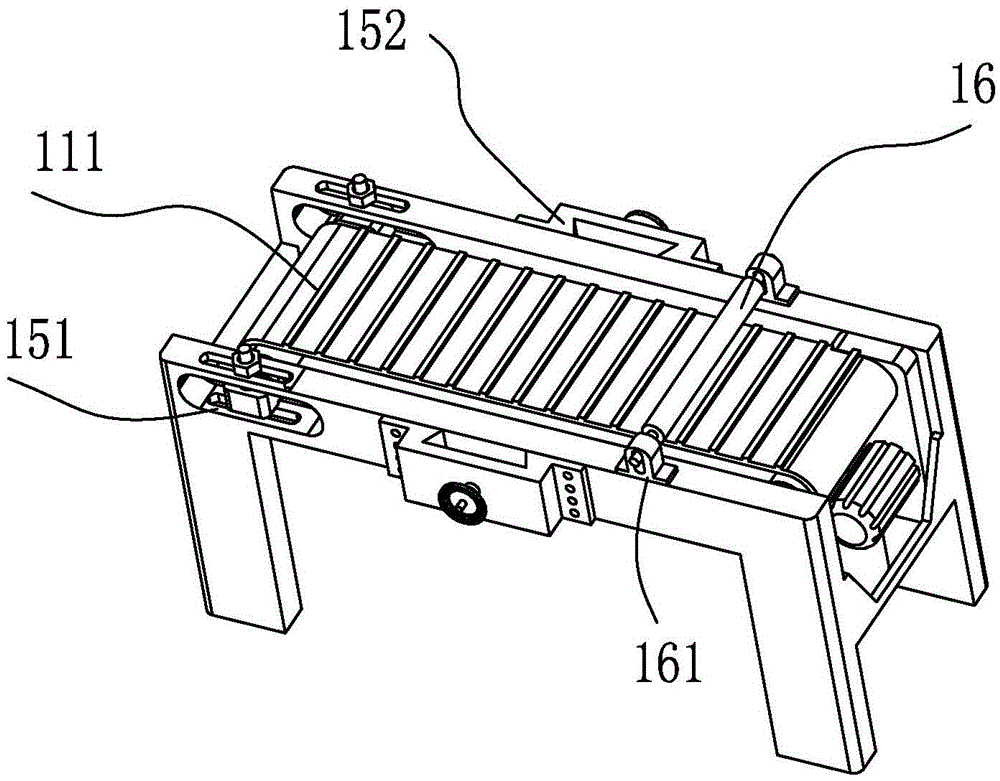

[0020] An automatic dust removal plate brush system, the whole brush machine includes a transmission platform 1, on which a brush system 2 is arranged, and the transmission platform uses a conveyor belt 11 for transmission, including a driving transmission shaft 12 and a driven transmission shaft 13. The driving drive shaft is connected with a drive motor 17, the drive motor is connected with a gearbox 18, and the gearbox is connected with a control panel. The control panel can control the speed of the drive drive shaft, thereby controlling the transmission speed of the conveyor belt. There is an anti-deviation adjustment device, which side of the conveyor belt deviates, you can use the anti-deviation adjustment device to adjust to prevent the plate from being transported obliquely. The brush system includes a brush roller 21, a brush roller The s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com