Aluminum and aluminum alloy film removing agent and application thereof

A technology of aluminum alloy and film agent, applied in the field of aluminum and aluminum alloy electroplating, aluminum and aluminum alloy film remover, to achieve good electroplating effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

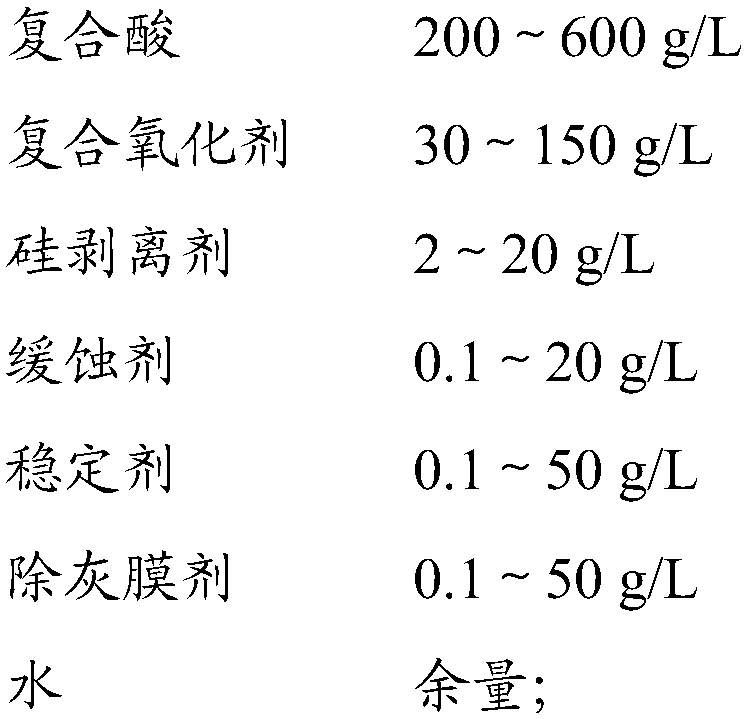

[0114] The composition of aluminum and aluminum alloy film remover is as follows:

[0115]

[0116] Wherein the comparative product is a component of a commonly used film remover.

[0117] The film remover solution is prepared by adding aluminum and aluminum alloy film remover to water at 500ml / L.

[0118] Film removal experiment:

[0119] (1) Take 6 aluminum alloys of the same size to be electroplated, and number them respectively. The numbers are: ①, ②, ③, ④, ⑤ and ⑥. In the aluminum and aluminum alloy film remover prepared in the above table. Specifically, ① placed in product 1, ② placed in product 2, ③ placed in product 3, ④ placed in product 4, ⑤ placed in product 5, ⑥ placed in the comparison product . After 120 seconds, take it out and observe.

[0120] (2) Perform electroplating on the aluminum alloy sheet after film removal under the same conditions.

[0121] The electroplating step adopts the above electroplating solution components and electroplating condit...

Embodiment 2

[0129] The composition of the aluminum alloy aluminum alloy film remover is as follows:

[0130]

[0131]

[0132] The film remover solution is prepared by adding aluminum and aluminum alloy film remover to water at 600ml / L.

[0133] Film removal experiment:

[0134] (1) Take 3 aluminum alloy sheets, respectively numbered ⑦, ⑧ and ⑨, after the same pretreatment, place ⑦~⑨ in the aluminum and aluminum alloy film remover prepared in the above table at 25 °C. Specifically, ⑦ is placed in the product 7, ⑧ is placed in the product 8, and ⑨ is placed in the product 9. After 120 seconds, take it out and observe.

[0135] (2) Perform electroplating on the aluminum alloy sheet after film removal under the same conditions.

[0136] The electroplating step adopts the above electroplating solution components and electroplating conditions or the existing commonly used electroplating solution components and electroplating conditions for electroplating.

[0137] Result analysis:

...

Embodiment 3

[0142] The composition of the aluminum alloy aluminum alloy film remover is as follows:

[0143]

[0144] The film remover solution is prepared by adding aluminum and aluminum alloy film remover to water at 400ml / L.

[0145] Film removal experiment:

[0146] (1) Take 3 pieces of aluminum alloy sheets, numbered ①, ② and ③ respectively. After the same pretreatment, place ①, ② and ③ in the aluminum and aluminum alloy film remover prepared in the above table at 25°C. . Specifically, ① placed in the product 10, ② placed in the product 11, and ③ placed in the product 12. After 120 seconds, take it out and observe.

[0147] (2) Perform electroplating on the aluminum alloy sheet after film removal under the same conditions.

[0148] The electroplating step adopts the above electroplating solution components and electroplating conditions or the existing commonly used electroplating solution components and electroplating conditions for electroplating.

[0149] Result analysis: ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com