PVC extrusion grade particulate material and preparation method thereof, and preparation method of extrusion product

A technology of extrusion grade and granular material, applied in the field of preparation, extrusion product preparation, PVC extrusion grade granular material, can solve the problems of poor product toughness, unstable surface resistance, poor dispersion, etc., to achieve comprehensive performance Good and stable, the effect of reducing body injury and reducing dust pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

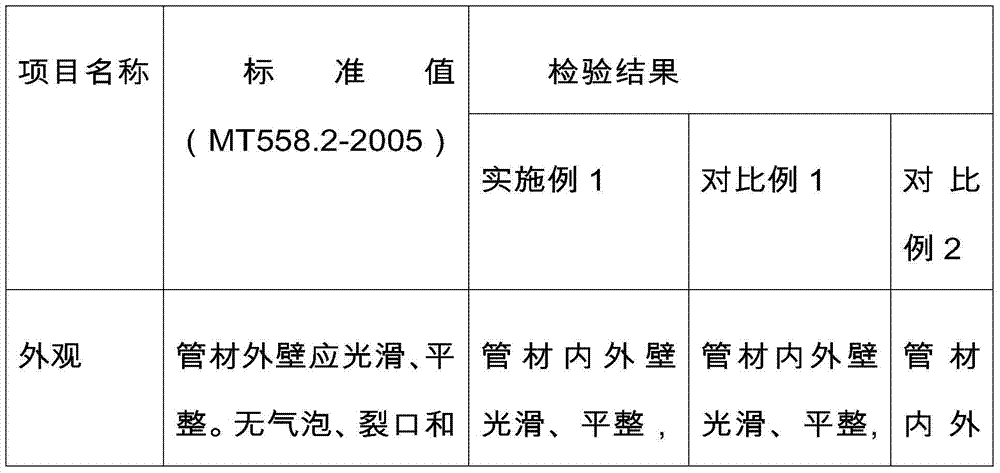

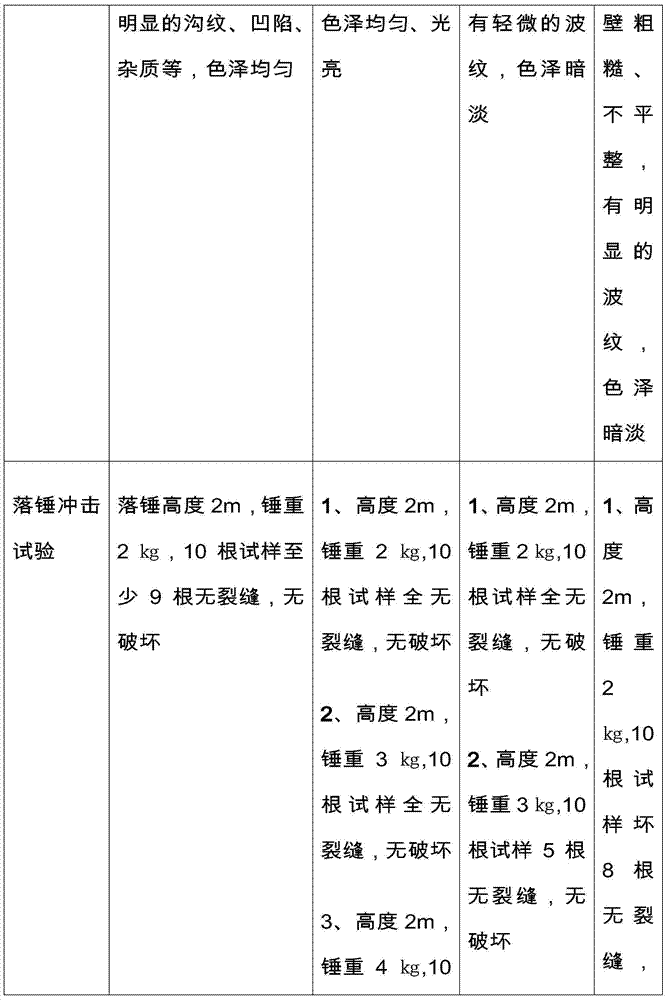

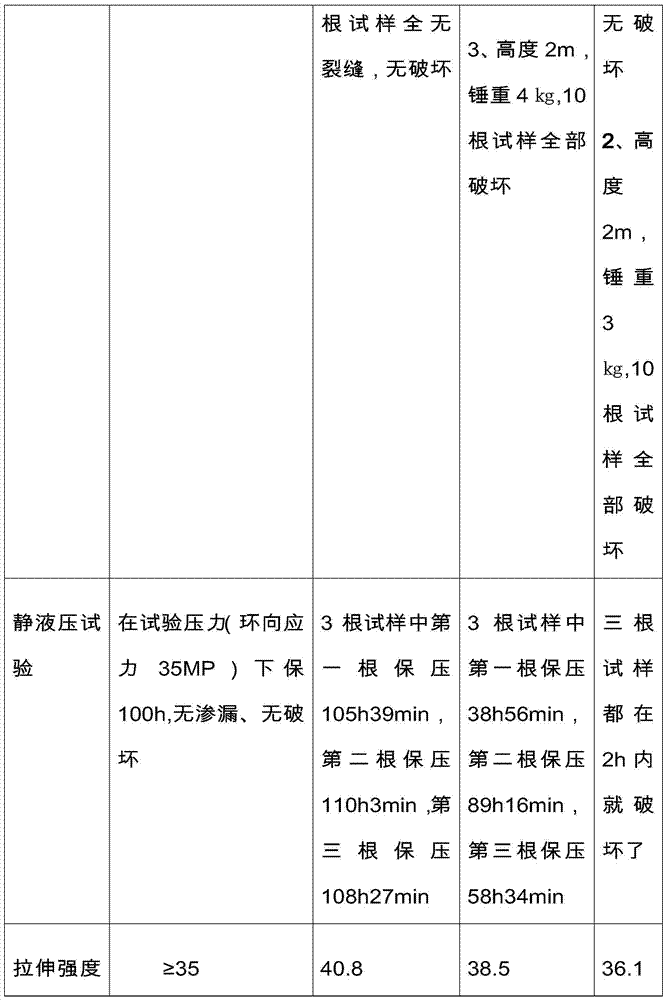

Examples

Embodiment 1

[0060] 1. Accurately weigh the raw materials according to the formula.

[0061] The formula is as follows: PVC SG-5 type resin: 66%, lead salt composite stabilizer: 4%, impact modifier MBS resin: 10%, EBS: 1%, lead stearate: 1%, ethylene oxide wax: 1%, PE wax 2%, conductive carbon black: 10%, ACR processing modifier: 2%, calcium carbonate: 3%; prepare 100kg of PVC extrusion grade pellets from the raw materials of the above formula.

[0062] 2. Pre-mix the weighed raw materials through a mixer to make powder.

[0063] Set the hot mixing temperature to 115°C. After the materials are stirred and rubbed at high speed, most of the volatiles are discharged, and the dispersion of various raw materials is good. When the temperature of the materials rises to 115°C, the materials are automatically discharged to the cold mixer; The temperature of the machine is set to 40°C, and the material is cooled by the low speed of the cold mixer and the circulating water in the jacket. When the te...

Embodiment 2

[0069]The formula is as follows: PVC SG-5 type resin: 60%, calcium zinc composite stabilizer: 4%, impact modifier CPE resin: 15%, lubricant (EBS: 1%, ethylene oxide wax: 2%, PE wax 1%), conductive carbon black: 11%, ACR processing modifier: 1%, talcum powder: 5%; 100kg of PVC extrusion-grade pellets were prepared from the raw materials of the above formula.

[0070] The preparation method of PVC extrusion-grade pellets and pipes is the same as in Example 1.

Embodiment 3

[0072] The formula is as follows: PVC SG-5 type resin: 66%, organotin stabilizer: 2%, impact modifier (CPE: 8%, ACR: 2%), lubricant (calcium stearate: 0.5%, oxidation Ethylene wax: 0.5%, PE wax 1%), conductive graphite: 13%, ACR processing modifier: 3%, mica powder: 3%, halogen flame retardant: 1%; 100kg of PVC extrusion grade pellets.

[0073] The preparation method of PVC extrusion-grade pellets and profiles is the same as in Example 1 to obtain PVC profiles.

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com