Pneumatic tire

a pneumatic tire and tread technology, applied in the field of pneumatic tires, can solve the problems of deterioration of tire durability and damage to the tread surface, and achieve the effects of reducing the stiffness of the tread, preventing stone retention in the small hole, and suppressing road nois

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

examples

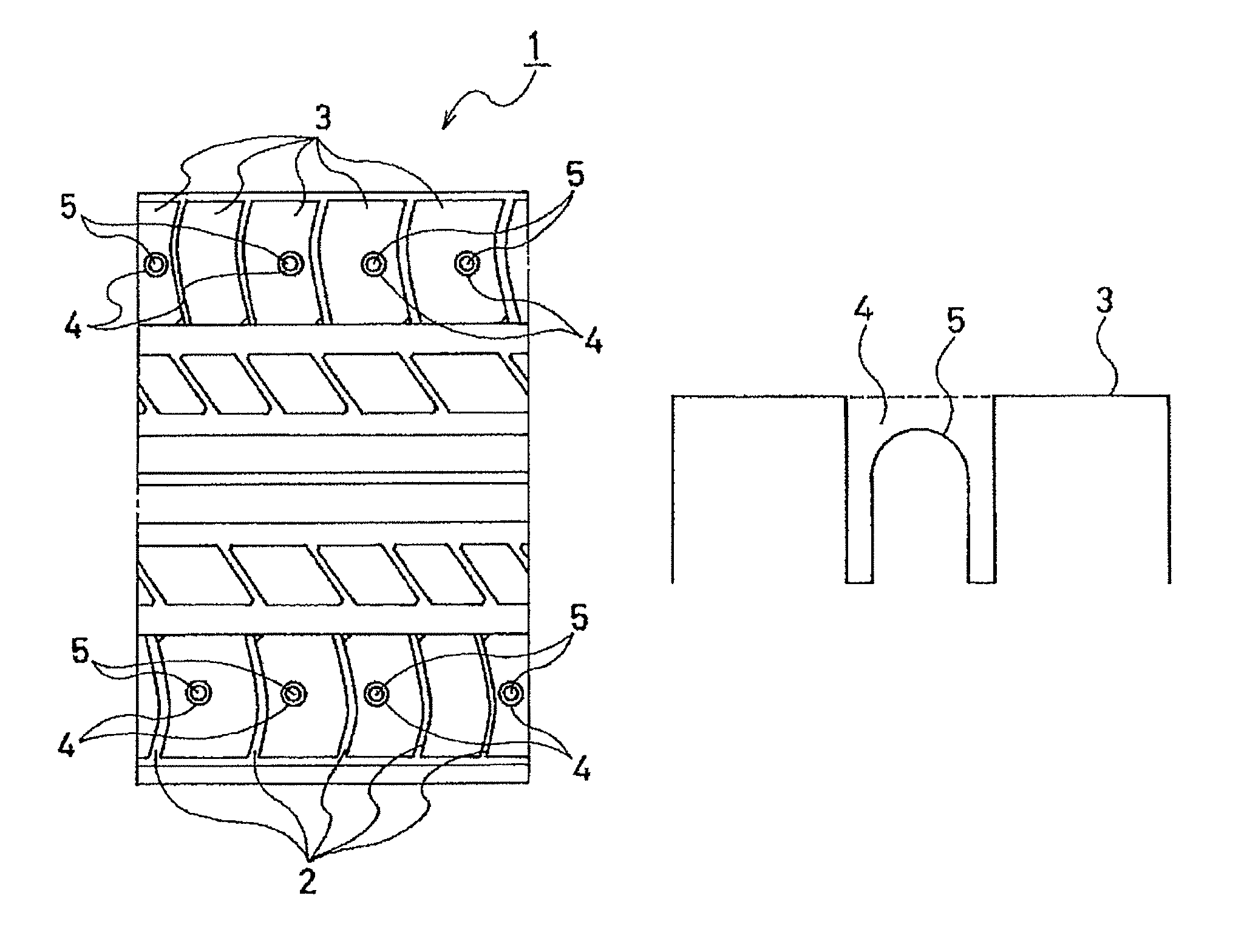

[0043]Seven kinds of pneumatic tires of Comparative Examples 1 to 3 and Examples 1 to 4 were fabricated. All seven kinds of pneumatic tires commonly had a tire size of 215 / 60R16 95H, a tread pattern of FIG. 1, and were provided with small holes having a diameter of 5 mm in shoulder sections. Specifications of the small holes and projections were different among the pneumatic tires as shown in Table 1.

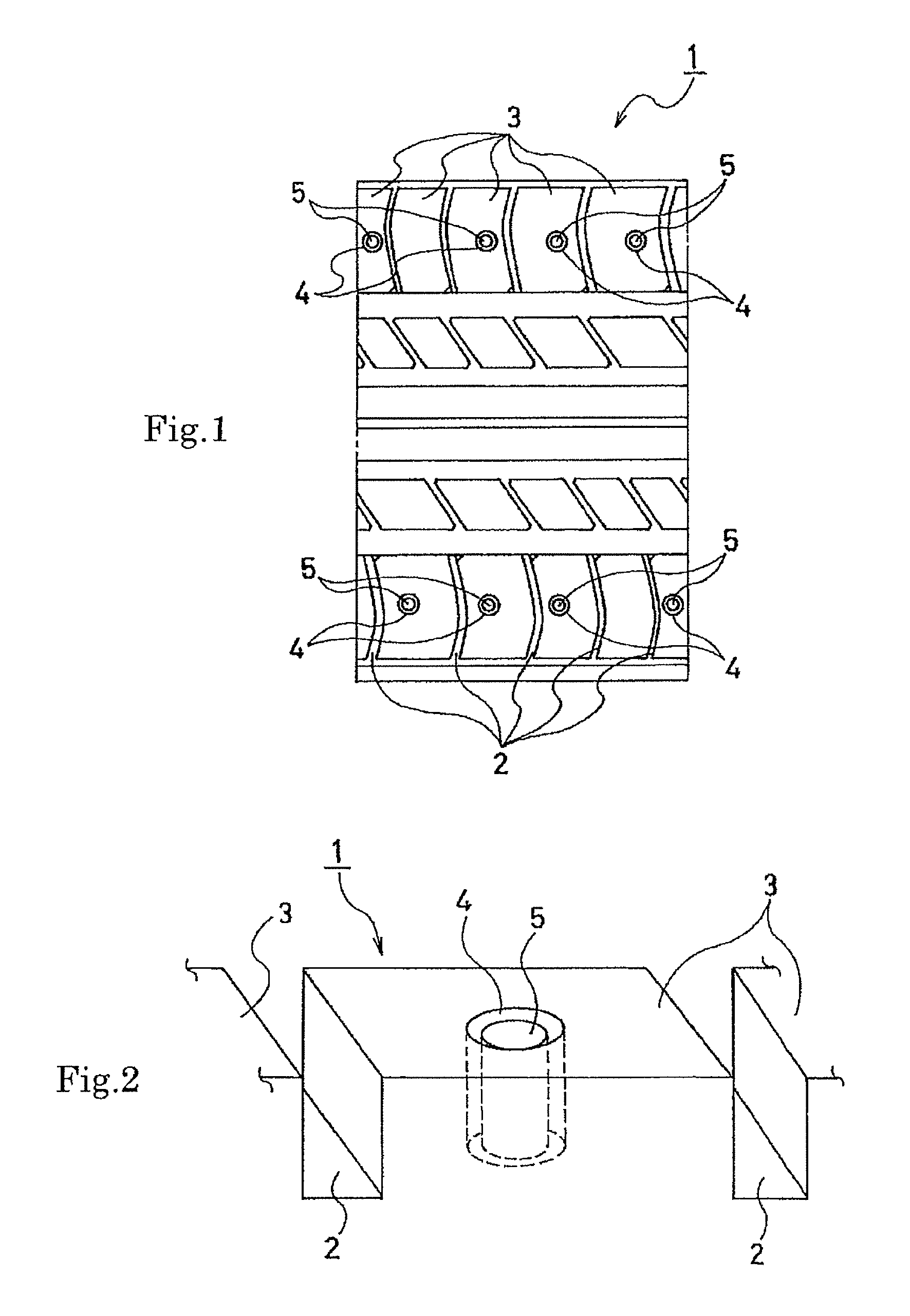

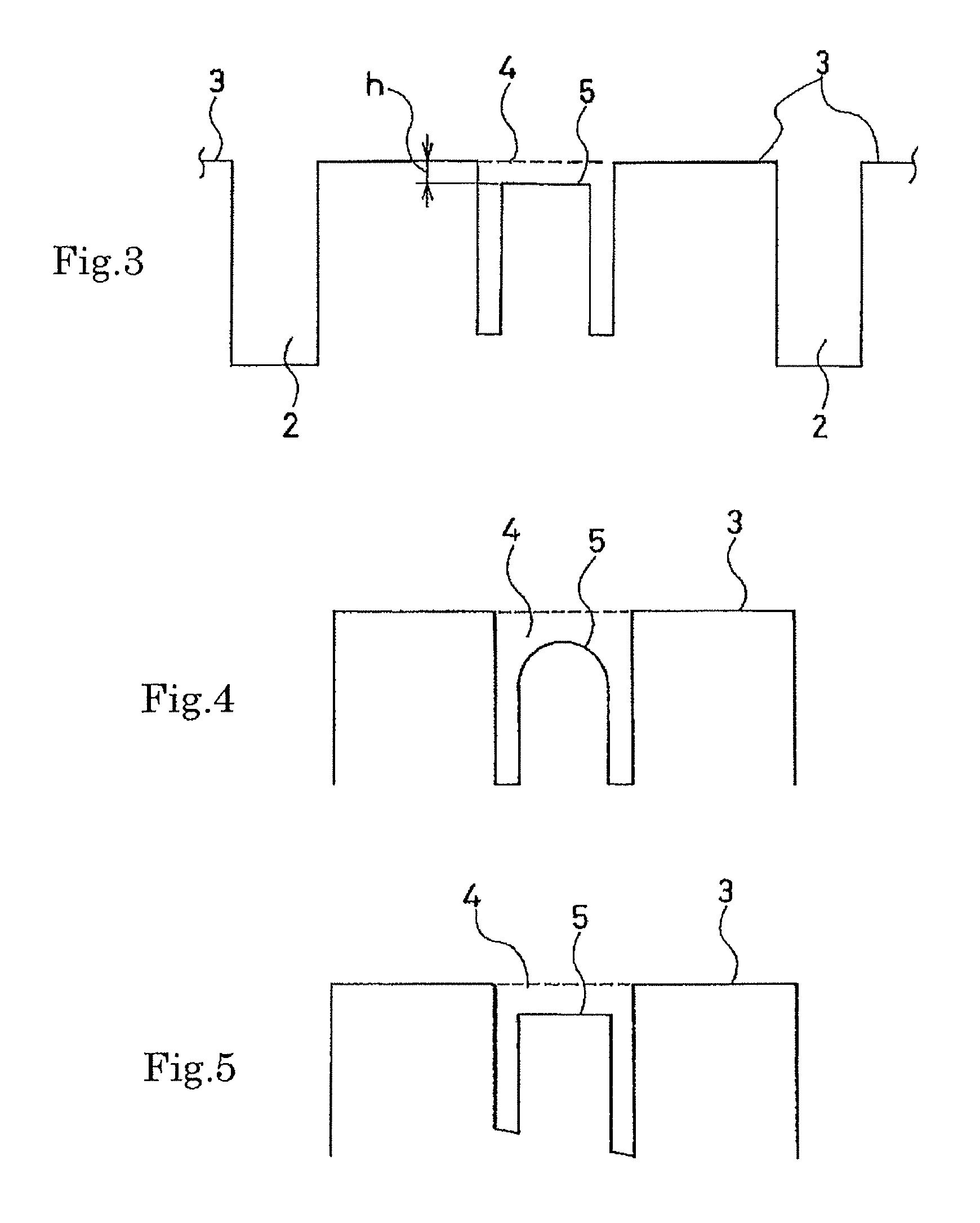

[0044]Comparative Example 1 is an example where only small holes were provided, but no projections were provided. Comparative Examples 2 and 3 are examples where columnar projections were provided. Comparative Example 2 is an example where the distance between the small hole and the projection was as narrow as 0.5 mm, while Comparative Example 3 is an example where upper ends of the projections were flush with the tread surface. Each of Examples 1 to 4 is an example where projections were provided. Example 1 is an example where columnar projections were provided, the distance between th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com