Acoustic barrier

A technology of sound barrier and sound-absorbing panel, applied in the field of high-speed railway sound barrier and high-speed railway noise control, can solve the problem of installation and fixed structure without further consideration of on-site construction needs, no new material technology exploration, sound-absorbing panels are not easy to process, etc. problems, to achieve the effect of convenient material transportation, excellent noise reduction function, and dimensional stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention is specifically described below by way of embodiment, and present embodiment is only used to further illustrate the present invention, but can not be interpreted as the restriction to protection scope of the present invention, some non-compliances that those skilled in the art make according to the content of the present invention above-mentioned Essential improvements and adjustments also belong to the protection scope of the present invention.

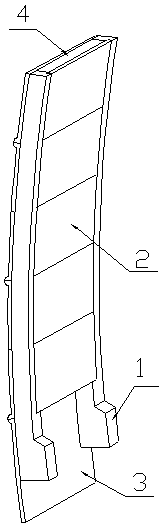

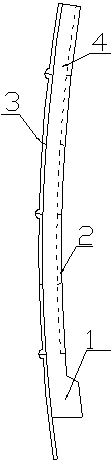

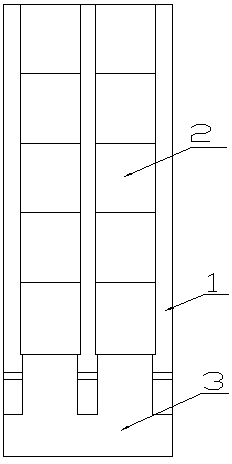

[0027] to combine Figure 1 to Figure 5 .

[0028] As shown in the figure, the sound barrier includes supporting rib columns 1 arranged continuously and at intervals along the railway track line. The supporting rib columns 1 are fixedly installed on the structure of the railway foundation 6, and the side of the railway traffic surface between every two supporting rib columns 1 is installed and fixed. There is a sound-absorbing board 2, and a backboard 3 is installed and fixed on the back side, and a holl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Pore diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com