Manufacturing method of cement-based ceramsite porous ballastless track acoustic board

A technology of ballastless track and production method, which is applied in the field of sound-absorbing materials, can solve the problems of difficult guarantee of strength, complicated manufacturing process, and high cost, and achieve good sound-absorbing effect and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

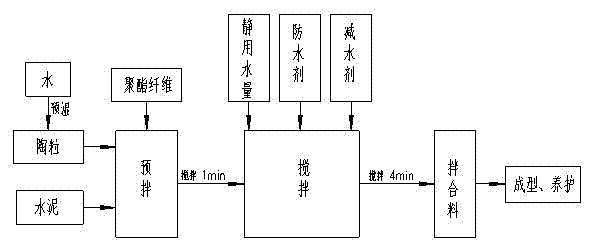

[0021] 1. process such as figure 1 shown.

[0022] The specific steps are:

[0023] (1) The raw materials are composed of ceramsite, cement, water, polyester fiber, water reducing agent and waterproofing agent. The mass percentages of ceramsite, cement, water, polyester fiber, water reducing agent and waterproofing agent are respectively: 54%, 36%, 8.5%, 0.3%, 0.8% and 0.5%; among them, ceramsite acts as a skeleton, 70% of particle size is 2.5-4mm, 20% of particle size is 1.5-2.5 mm, and 10% of particle size is 0-1.5 mm .

[0024] (2) After prewetting the ceramsite with water, add cement and polyester fiber and mix for 1 minute, then add waterproofing agent and water reducing agent and stir for 4 minutes, add water while stirring until the amount of water added is equal to the static water amount, and the mixture is prepared material.

[0025] (3) Pour the mixture prepared in step (2) into the mold, and evenly coat the inner surface of the mold with engine oil to help dem...

Embodiment 2

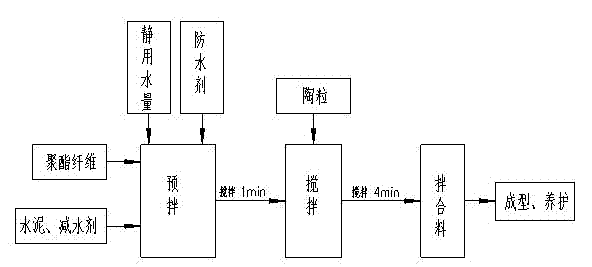

[0040] 1. Process flow such as figure 2 shown.

[0041] The specific steps are:

[0042] (1) The raw materials are composed of ceramsite, cement, water, polyester fiber, water reducing agent and waterproofing agent. The mass percentages of ceramsite, cement, water, polyester fiber, water reducing agent and waterproofing agent are: 50%, 38%, 10%, 0.2%, 1.2% and 0.6%; among them, ceramsite acts as a skeleton, with a particle size of 2.5-4 mm accounting for 70%, a particle size of 1.5-2.5 mm for 20%, and a particle size of 0-1.5 mm for 10% .

[0043] (2) Mix cement, polyester fiber, waterproofing agent and water reducing agent for 1 minute, add water while stirring until the amount of water added is equal to the static water amount, then add ceramsite and stir for 5 minutes to prepare the mixture.

[0044] (3) Pour the mixture prepared in step (2) into the mold, and evenly coat the inner surface of the mold with engine oil to help demoulding after molding. After putting on ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

| sound absorption coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com