Self-supporting thermal insulation hollow floor slab and construction method thereof

A technology of hollow floor slab and construction method, which is applied in the direction of floor slabs, passive houses, building components, etc., can solve the problems of unfavorable environmental protection, energy saving and emission reduction, increased use cost of the floor, unfavorable decoration, etc., to save maintenance costs, reduce production costs, Conducive to the effect of decoration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments, but not as a limitation of the present invention.

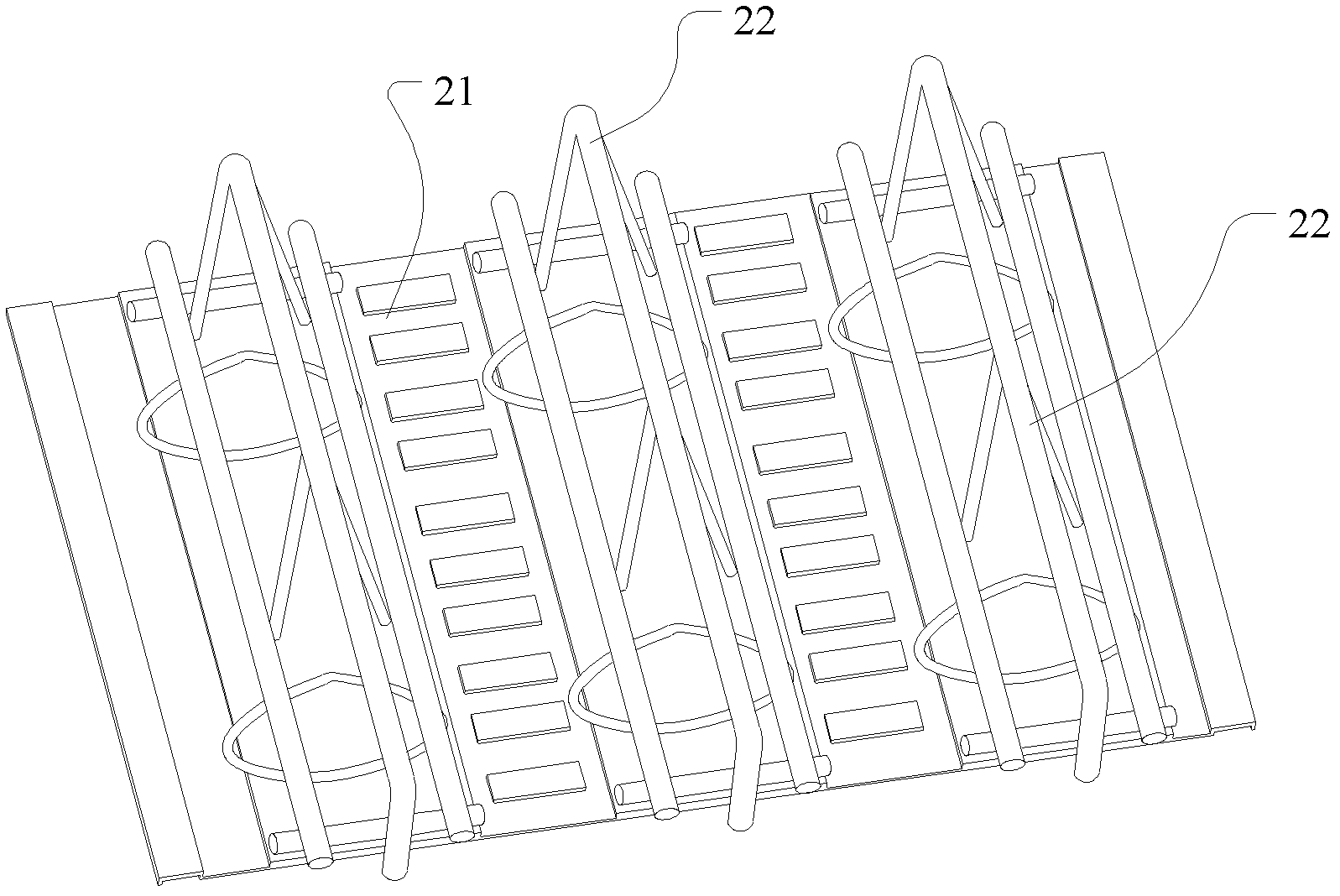

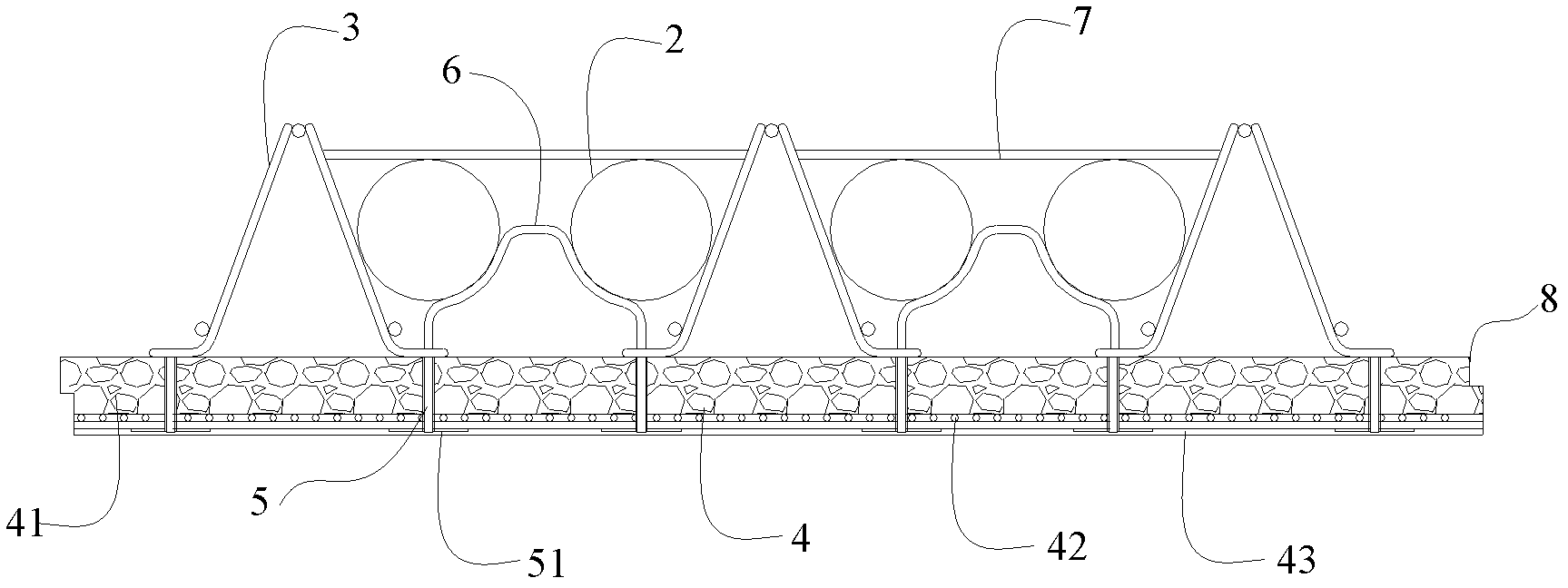

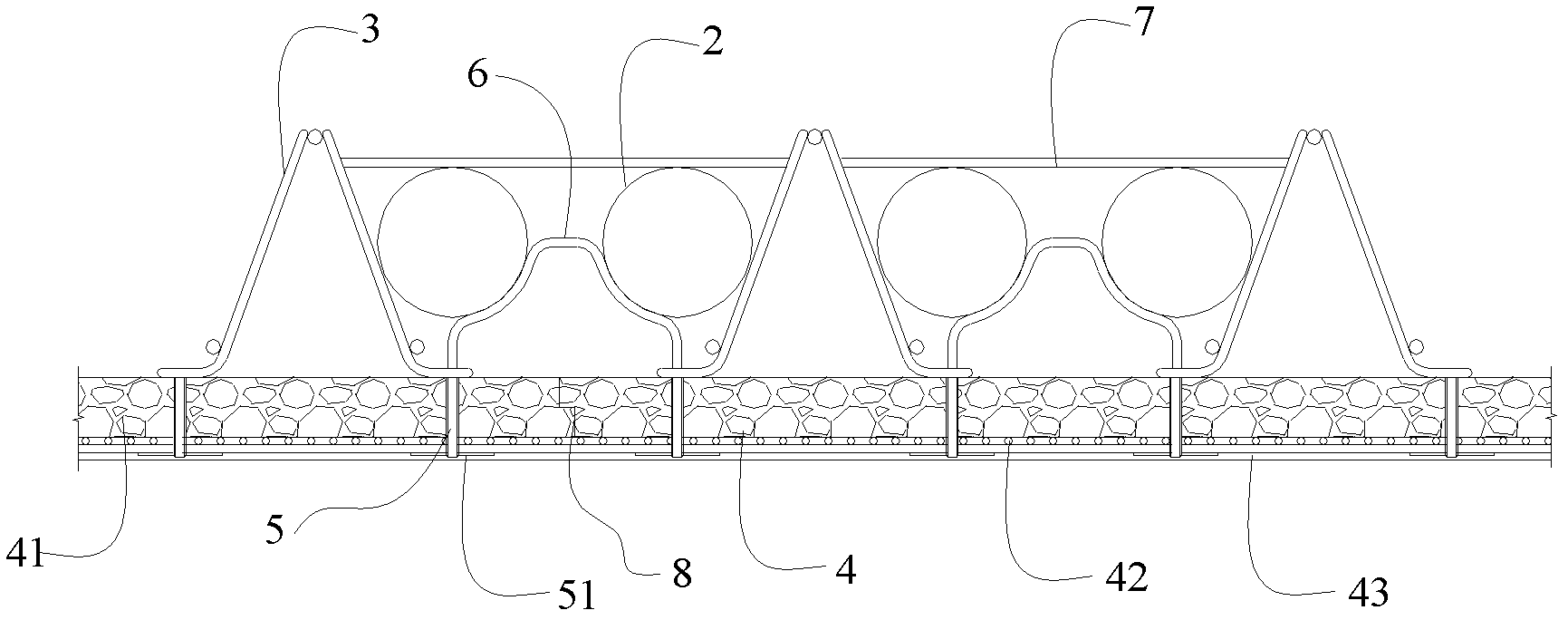

[0048] Such as figure 2 and image 3 As shown, a self-supporting thermal insulation hollow floor slab 9 according to the embodiment of the present invention includes a plurality of frames composed of bottom slabs 4 and multiple steel bar trusses 3 erected above the bottom slab 4 and connected to the bottom slab 4, two adjacent The bottom plates 4 of the frames are connected, and concrete 1 is poured on the steel bar trusses 3 . Wherein, the base plate 4 includes a steel wire mesh 42 and a thermal insulation board 41 on the steel wire mesh 42 (of course, the steel wire mesh can also be replaced by a steel mesh), and the bottom of the steel bar truss 3 is connected to the base plate 4 through a plurality of connectors 5 . Specific as figure 2 and image 3 As shown, the upper end of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com