Decoration acoustic absorption sheet material of tripolite and method for producing the same

A diatomaceous earth and board technology, applied in the field of chemical building materials, can solve the problems of mineral wool application limitations, poor processing performance, and low density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

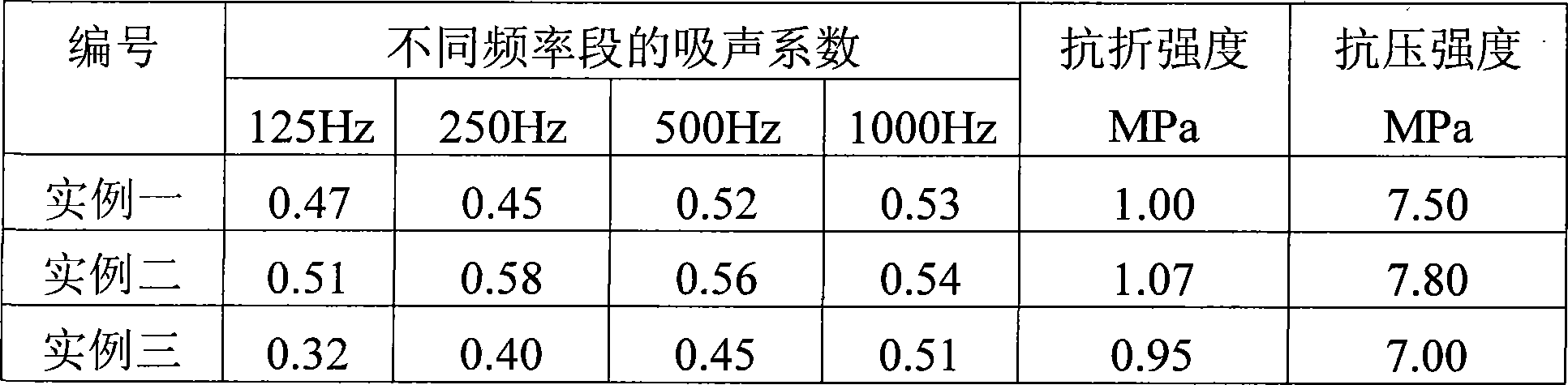

Examples

Embodiment 1

[0016] Weigh 1400g of diatomite, 500g of gypsum, 60g of titanium dioxide, 30g of polyvinyl alcohol, and 10g of pulp fiber into a 15-liter mortar mixer and stir evenly for 20 minutes. After the materials are evenly dispersed, stir evenly with 2000ml of water to prepare into a paste-like slurry.

[0017] Cast the above-mentioned paste slurry into molds with length, width, and height of 200mm, 200mm, and 15mm respectively, oscillate evenly, remove the excess slurry on the upper part with a scraper, remove the mold after curing for 24 hours, and dry the sample naturally.

Embodiment 2

[0019] Weigh 1600g of diatomite, 360g of gypsum, 20g of iron oxide yellow, 18g of polyvinyl acetate redispersed rubber powder, and 2g of polypropylene fiber into a 15-liter mortar mixer, and stir evenly for 30 minutes. After the materials are evenly dispersed, use Stir 3000ml of water evenly to make a paste-like slurry.

[0020] Cast the above-mentioned paste slurry into molds whose length, width, and height are 200mm, 200mm, and 15mm respectively, oscillate evenly, remove the excess slurry on the upper part with a scraper, remove the mold after curing for 24 hours, and put the sample into a drying box 80°C for 24h.

Embodiment 3

[0022] Weigh 1500g of diatomite, 430g of gypsum, 40g of iron oxide blue, 25g of polyvinyl acetate redispersed rubber powder, and 5g of polypropylene fiber into a 15-liter mortar mixer, and stir evenly for 30 minutes. After the materials are evenly dispersed, use Stir 3000ml of water evenly to make a paste-like slurry.

[0023] Cast the above-mentioned paste slurry into molds with length, width, and height of 200mm, 200mm, and 15mm respectively, oscillate evenly, remove the excess slurry on the upper part with a scraper, remove the mold after curing for 24 hours, and dry the sample naturally.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com