Crack self-healing ultra-high performance cement-based composite material and preparation method in cold regions

An ultra-high performance, composite material technology, applied in the field of building materials and basic engineering construction, can solve the problems of inconvenient construction, mixing and vibrating, and achieve the effects of reducing development, improving hydration reaction speed, and improving flexural resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0039] The preparation method of the crack self-healing ultra-high performance cement-based composite material in the cold region, the specific steps are as follows:

[0040] S1. Mix ethanol, water, tetraethoxysilane, 3-aminopropyltriethoxysilane, and ammonium hydroxide to obtain a white colloidal dispersion, remove impurities, and dry the obtained white solid to obtain the amino functionalized Modified nano silicon dioxide, standby;

[0041] S2. Hydrolyzing tetraethoxysilane at a pH of 2 to obtain a precursor; stirring and mixing the precursor with epoxy resin and water to form an emulsion, and adjusting the pH of the emulsion to 10 with 0.1M ammonium hydroxide solution, Obtain the microcapsule suspension, let it stand for aging, centrifuge, and the obtained solids are washed and dried in sequence to obtain the silica-coated epoxy resin microcapsules for subsequent use;

[0042] S3. Weigh 573-705 parts of cement, 361-487 parts of fly ash, 90-240 parts of silica fume, 530-636...

Embodiment 1

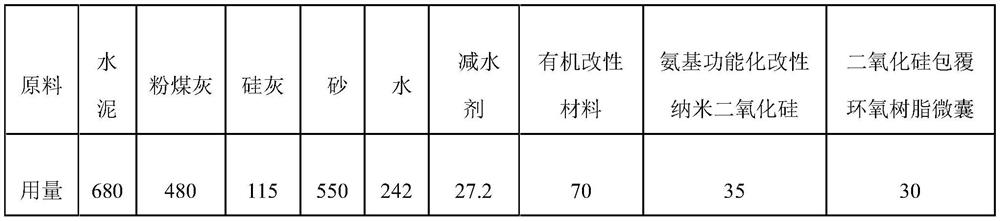

[0050] Ultra-high performance cement-based composite material with high workability and compressive strength of 120MPa~160MPa, its unilateral dosage ratio (kg / m 3 )As shown in Table 1:

[0051] Table 1 Proportion of self-healing cement-based composites with compressive strength of 120MPa-160MPa (kg / m 3 )

[0052]

[0053] The capillary water absorption test was carried out on the cement-based composite material prepared in Example 1, and it was measured that under the cracks within 300 μm, the healing period was 28 days, and the weight gain was 7.8 g.

Embodiment 2

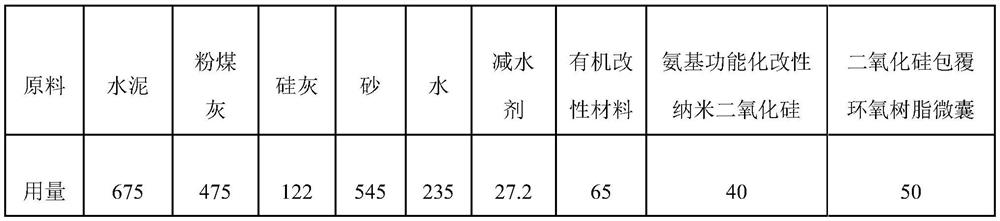

[0055] Ultra-high-performance cement-based composite materials with high workability and compressive strength of 120MPa to 160MPa, the unilateral dosage ratio (kg / m 3 )As shown in table 2:

[0056] Table 2 Proportion of cement-based composite materials with self-healing and compressive strength of 120MPa~160MPa (kg / m3)

[0057]

[0058] The capillary water absorption test was carried out on the cement-based composite material prepared in Example 2, and it was measured that in cracks within 300 μm, the healing period was 28 days, and the weight gain was 7.3 g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com