Foaming cement

A foamed cement and cement technology, applied in the field of foamed cement, can solve the problems of long time required for setting and solidification, achieve significant economic and social benefits, improve impermeability, and improve the effect of hydration reaction speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

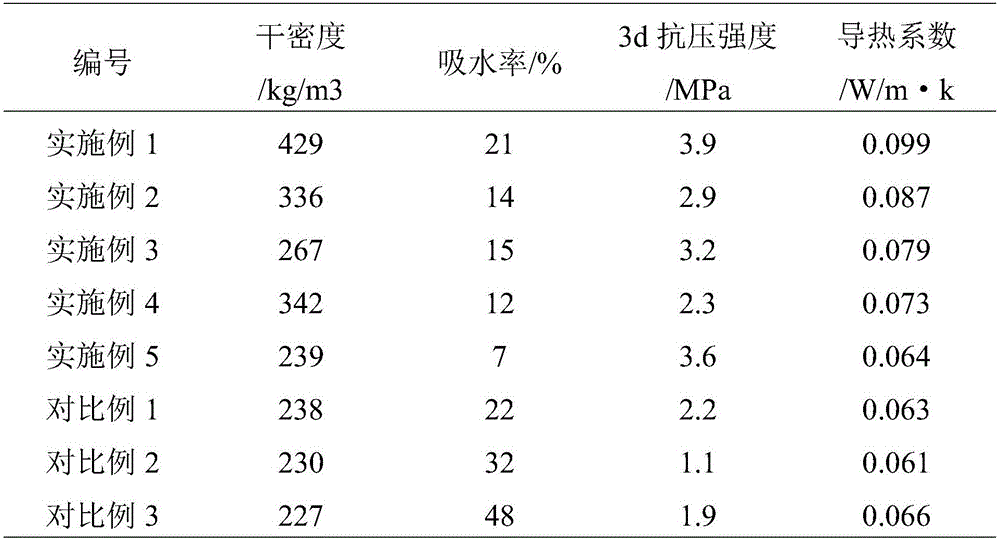

Embodiment 1

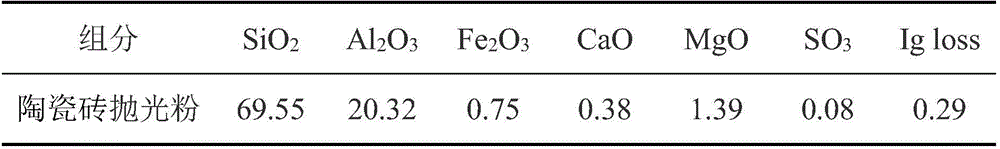

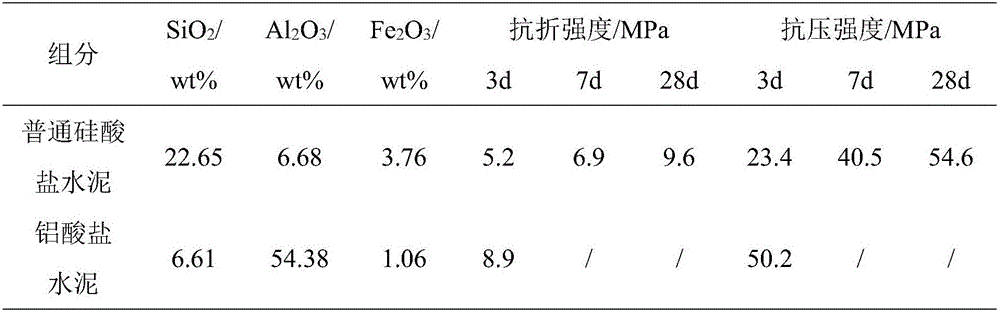

[0023] A foamed cement, comprising the following components in mass percentage: 30% cement, 5% ceramic tile polishing powder, 1% foaming component, 0.1% foam stabilizing component, 0.5% waterproofing component, and 0.5% reinforcing component , The balance is water.

[0024] Among them, the cement is composed of Portland cement and aluminate cement in a mass ratio of 5:1; the alumina content in aluminate cement is 40%; the specific surface area of ceramic tile polishing powder is greater than 600m 2 / kg; the foaming component is composed of hydrogen peroxide, fatty alcohol polyoxyethylene ether sodium sulfate and lauryl dimethyl betaine in a mass ratio of 5:2:1; the foam stabilizing component is composed of hydroxypropyl starch ether and lauryl Acyl diethanolamine is composed of 0.5:1 by mass ratio; the waterproof component is composed of water glass, sodium fluorosiliconate and triethanolamine phosphate by mass ratio of 1:2:1; the reinforcing component is composed of diethan...

Embodiment 2

[0026] A foamed cement, comprising the following components in mass percentage: 45% cement, 10% ceramic tile polishing powder, 4% foaming component, 1% foam stabilizing component, 2% waterproofing component, and 2% reinforcing component , The balance is water.

[0027] The cement is composed of Portland cement and aluminate cement in a mass ratio of 10:1; the alumina content in aluminate cement is 45%; the specific surface area of ceramic tile polishing powder is greater than 600m 2 / kg; the foaming component is composed of hydrogen peroxide, fatty alcohol polyoxyethylene ether sodium sulfate and lauryl dimethyl betaine in a mass ratio of 10:0.5:1; the foam stabilizing component is composed of hydroxypropyl starch ether and lauryl Acyl diethanolamine is composed of 2:1 by mass ratio; the waterproof component is composed of water glass, sodium fluorosilicone and triethanolamine phosphate by mass ratio of 2:0.5:1; the reinforcing component is composed of diethanol monoisopropa...

Embodiment 3

[0029] A foamed cement, comprising the following components in mass percentage: 40% cement, 8% ceramic tile polishing powder, 3% foaming component, 0.5% foam stabilizing component, 1% waterproofing component, and 1 reinforcing component %, the balance is water.

[0030] The cement is composed of Portland cement and aluminate cement in a mass ratio of 8:1; the alumina content in aluminate cement is 50%; the specific surface area of ceramic tile polishing powder is greater than 600m 2 / kg; the foaming component is composed of hydrogen peroxide, fatty alcohol polyoxyethylene ether sodium sulfate and lauryl dimethyl betaine in a mass ratio of 5:1:1; the foam stabilizing component is composed of hydroxypropyl starch ether and lauryl Acyl diethanolamine is composed of 1:1 mass ratio; the waterproof component is composed of water glass, sodium fluorosilicone and triethanolamine phosphate in a mass ratio of 1:1:1; the reinforcing component is composed of diethanol monoisopropanolami...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com