A method for preparing unburned bricks from offshore drilling waste mud

A waste mud and offshore drilling technology, which is applied in the field of resource utilization of drilling waste, can solve the problems that the land process cannot be completely copied, and achieve the effect of solving the problem of safe and environmentally friendly disposal, reducing the average pore size, and accelerating the hydration reaction speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

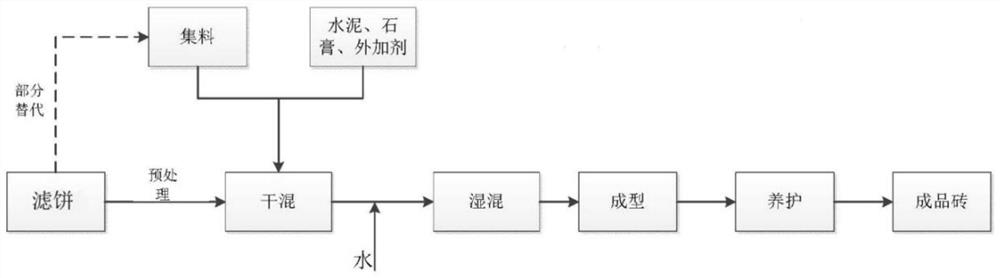

[0019] A method for preparing non-burning bricks with waste mud from offshore drilling, comprising the following steps:

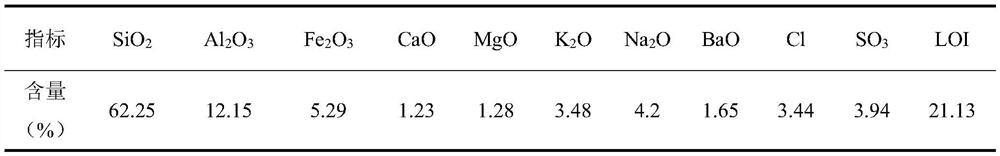

[0020] First, the block filter cake after landing is dried at 105℃±5℃ until the moisture content is less than 5%, crushed to below 6mm by a jaw crusher, then ball milled by a ball mill, and sieved with an 80-mesh square-hole sieve to The particle size is less than 0.5mm, and finally, under the condition of liquid-solid ratio of 4, washing with water for 30min, the chloride ion in the raw material is quickly removed, and the base material for making bricks is obtained. The chemical composition analysis of the base material is shown in Table 1.

[0021] Table 1 Chemical composition table of base materials

[0022]

[0023] As shown in Table 1, the main chemical component in the base material is SiO 2 , Al 2 O 3 , with the chemical components for the preparation of non-burning bricks. At the same time, the particle size is basically below 0.5mm, which ...

Embodiment 2

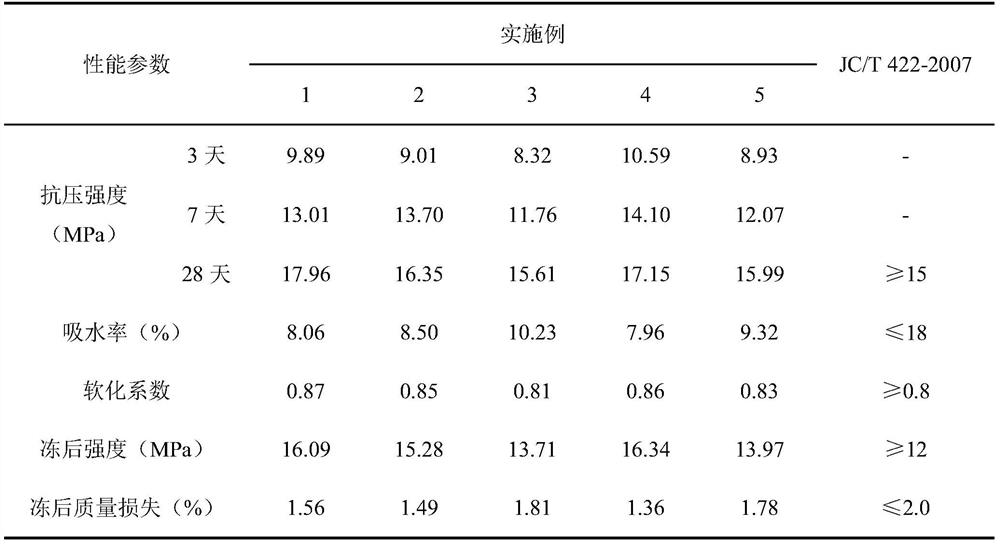

[0027] A method for preparing non-burning bricks with waste mud from offshore drilling, the same as Example 1, with the difference: when preparing dry mixture, the mass percentage of each component is 10% base material, 20% cement, 8% coarse aggregate, 57% ..5% fine aggregate, 4% gypsum and 0.5% polyvinyl alcohol.

Embodiment 3

[0029] A method for preparing non-burning bricks with waste mud from offshore drilling, the same as Example 1, with the difference: when preparing dry mixture, the mass percentage of each component is 15% base material, 20% cement, 8% coarse aggregate, 52.5% % fine aggregate, 4% gypsum and 0.5% polyvinyl alcohol.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com