Anti-crack concrete and preparation method thereof

A technology of concrete and polypropylene fibers, applied in the field of concrete, can solve the problems of low compressive strength of concrete, decreased compressive strength, difficulty in meeting the needs of special projects, etc., so as to improve mechanical properties and durability, and improve adhesion. , enhance the effect of bonding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

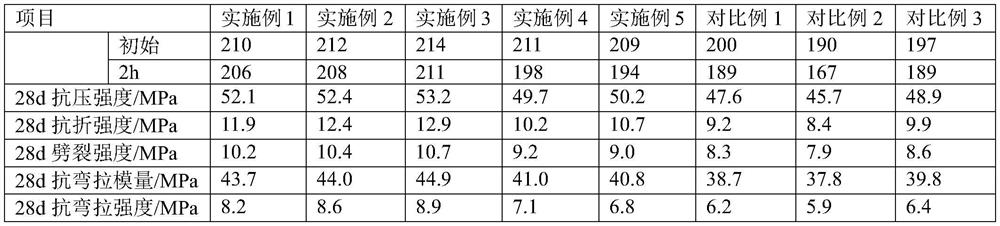

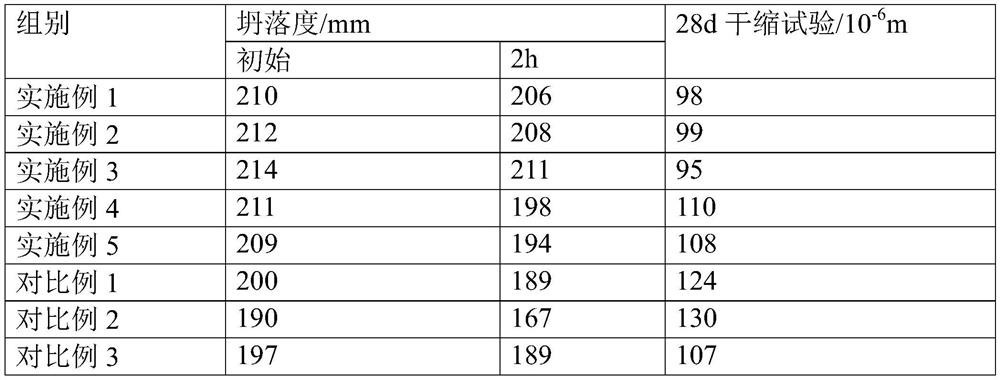

Examples

Embodiment 1

[0025] Raw material composition (parts by weight): 100 parts of water, 200 parts of Portland cement, 30 parts of epoxy resin modified polypropylene fiber, 10 parts of reinforcing fiber, 9 parts of calcium lignosulfonate water reducer, calcium aluminate expansion agent 7 parts, 30 parts of fly ash, 30 parts of coarse aggregate, 20 parts of fine aggregate, 0.1 part of sodium dioctyl succinic acid sulfonate. Coarse aggregate is crushed stone with a diameter of 10-20mm; fine aggregate is natural sand with a diameter of less than 5mm. The reinforcing fiber is a mixture of polyvinyl alcohol fiber and polypropylene short fiber with a mass ratio of 3:3.

[0026] Epoxy resin modified polypropylene fiber is prepared by the following method:

[0027] S1. Add polypropylene fiber to ethanol solution containing 2wt% silane coupling agent, heat to 70°C, react for 1h, filter, and dry to obtain modified polypropylene fiber;

[0028] The silane coupling agent is a complex mixture of γ-aminopr...

Embodiment 2

[0032] Raw material composition (parts by weight): 150 parts of water, 400 parts of Portland cement, 50 parts of epoxy resin modified polypropylene fiber, 20 parts of reinforcing fiber, 14 parts of naphthalene-based water reducer, 10 parts of sulphoaluminate expansion agent , 70 parts of fly ash, 70 parts of coarse aggregate, 50 parts of fine aggregate, and 0.3 parts of sodium dioctyl succinic acid sulfonate. Coarse aggregate is crushed stone with a diameter of 10-20mm; fine aggregate is natural sand with a diameter of less than 5mm. The reinforcing fiber is a mixture of polyvinyl alcohol fiber and polypropylene short fiber with a mass ratio of 3:5.

[0033] Epoxy resin modified polypropylene fiber is prepared by the following method:

[0034] S1. Add polypropylene fiber to ethanol solution containing 5wt% silane coupling agent, heat to 90°C, react for 2h, filter and dry to obtain modified polypropylene fiber;

[0035] The silane coupling agent is a complex mixture of γ-amin...

Embodiment 3

[0039]Composition of raw materials (parts by weight): 125 parts of water, 300 parts of Portland cement, 40 parts of epoxy resin modified polypropylene fiber, 15 parts of reinforcing fiber, 12 parts of polycarboxylate water reducer, 9 parts of alunite expansion agent, 50 parts of fly ash, 50 parts of coarse aggregate, 35 parts of fine aggregate, 0.2 part of sodium dioctyl succinic acid sulfonate. Coarse aggregate is crushed stone with a diameter of 10-20mm; fine aggregate is natural sand with a diameter of less than 5mm. The reinforcing fiber is a mixture of polyvinyl alcohol fiber and polypropylene short fiber with a mass ratio of 3:4.

[0040] Epoxy resin modified polypropylene fiber is prepared by the following method:

[0041] S1. Add polypropylene fiber to ethanol solution containing 3.5wt% silane coupling agent, heat to 80°C, react for 1.5h, filter, and dry to obtain modified polypropylene fiber;

[0042] The silane coupling agent is a complex mixture of γ-aminopropyltr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com