Industrial solid waste-based inorganic paste filling material, preparation method and rapid filling method

A technology for filling industrial solid waste and paste, which is applied to filling materials, mining equipment, earth square drilling and mining, etc. It can solve the problems of high filling cost and difficult filling, expand the scope of application, improve filling efficiency, and improve early strength Effect with Final Strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] Example 1 A preparation method and rapid filling method of an industrial solid waste-based inorganic paste filling material

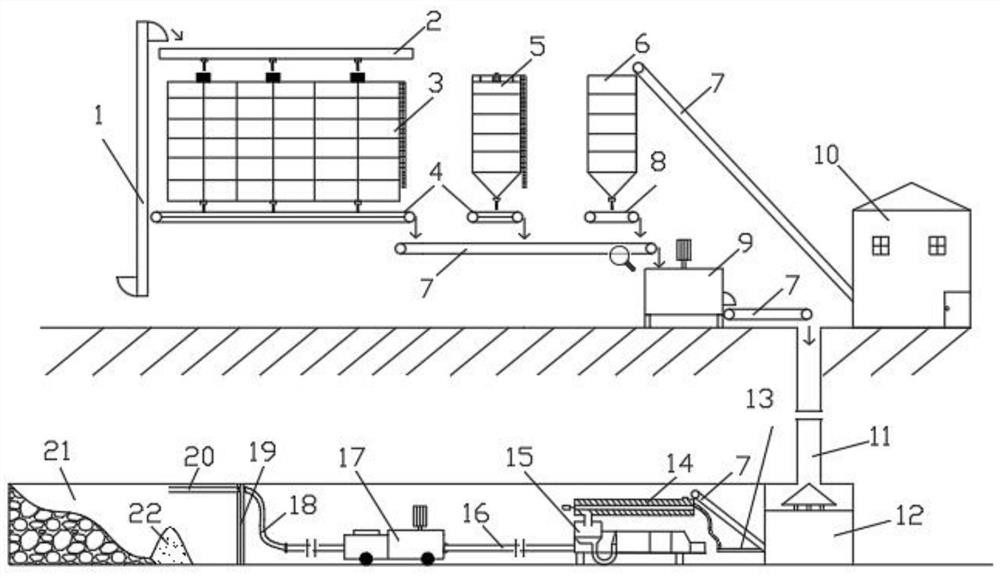

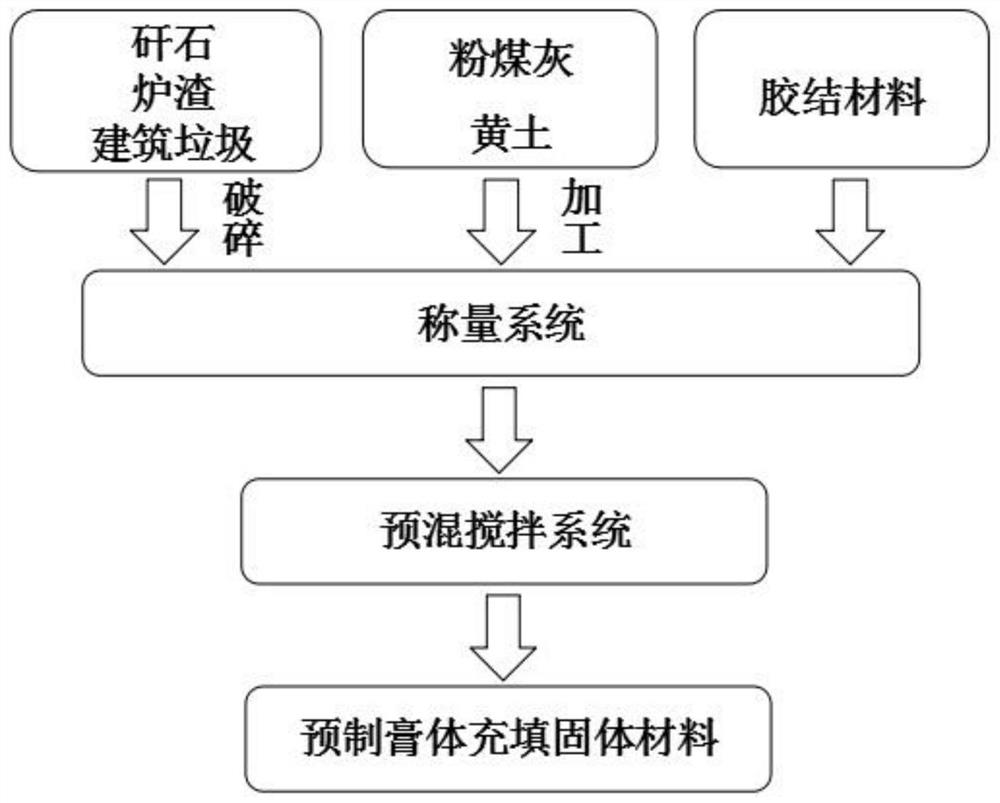

[0042] A preparation method and rapid filling method of an industrial solid waste-based inorganic paste filling material, part of the process flow chart can be found in figure 1 ,details as follows:

[0043] 1) Preparation method of industrial solid waste-based inorganic paste filling material

[0044] 1) Preparation of solid waste filling cementing material

[0045] 11) Take the desulfurized gypsum with a moisture content of 12wt%, dry it until the moisture content is 8wt%, and then use a belt conveyor to transport it to the mill for rough grinding, then heat and dry it with circulating hot air until the moisture content is 2.8wt%, and then Continuously calcined at 180°C for 1 hour, and finally pulverized by a pulverizer to obtain a modified industrial by-product gypsum, and its 80 μm negative pressure sieve residue <2%;

[0046] Get 0.15kg pol...

Embodiment 2

[0061] Embodiment 2 A kind of preparation method of industrial solid waste-based inorganic paste filling material

[0062] 1) Preparation method of industrial solid waste-based inorganic paste filling material

[0063] 1) Preparation of solid waste filling cementing material

[0064] 11) Take fluorogypsum with a moisture content of 12.8wt%, dry it until the moisture content is 7.5wt%, and then use a belt conveyor to transport it to the mill for rough grinding, then heat and dry it with circulating hot air until the moisture content is 2.7wt% , and then continuously calcined at 200°C for 1.1h, and finally pulverized by a pulverizer to obtain a modified industrial by-product gypsum, and the 80μm negative pressure sieve residue <2%;

[0065] Get 0.3kg polycarboxylic acid (high-efficiency water reducer, powder), 0.1kg sodium silicate (powder), 0.1kg melamine (powder) and mix uniformly through a mixer to prepare an admixture, wherein polycarboxylic acid, The ratio of sodium silic...

Embodiment 3

[0080] Embodiment 3 A kind of preparation method of industrial solid waste-based inorganic paste filling material

[0081] 1) Preparation method of industrial solid waste-based inorganic paste filling material

[0082] 1) Preparation of solid waste filling cementing material

[0083] 11) Take phosphogypsum with a moisture content of 12.1wt%, dry it until the moisture content is 7.7wt%, and then use a belt conveyor to transport it to the mill for rough grinding, then heat and dry it with circulating hot air until the moisture content is 2.9wt% , and then continuously calcined at 190°C for 1.5h, and finally pulverized by a pulverizer to obtain a modified industrial by-product gypsum, and the 80μm negative pressure sieve residue <2%;

[0084] Get 0.2kg polycarboxylic acid (superplasticizer, powder), 0.05kg sodium silicate (powder), 0.05kg melamine (powder) and mix them uniformly through a mixer to prepare an admixture, wherein polycarboxylic acid, The ratio of sodium silicate t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com