Modified limestone powder-based mineral admixture and preparation method thereof

A mineral admixture and limestone powder technology, applied in the field of mineral admixtures, can solve the problems of difficulty in increasing the amount of limestone powder, restricting the application of limestone powder, and limiting the wide application, etc., achieving simple and feasible preparation methods and reducing the diffusion of chloride ions The coefficient, the effect of simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] The Blaine specific surface area is 350m 2 50 parts / kg of limestone powder, Blaine's specific surface area is 400m 2 50 parts / kg of slag powder, Blaine specific surface area 450m 2 4 parts per kg of calcined gypsum and 0.02 parts of triethanolamine are mechanically stirred, and the modified limestone powder-based mineral admixture is made after mixing evenly, wherein: slag powder is the molten slag discharged when smelting pig iron, and the 7-day activity index is not less than 75%, dry powder with an activity index of not less than 95% in 28 days, calcined gypsum is calcined by gypsum at a temperature of 850, CaSO 4 Dry powder with a content greater than 85%.

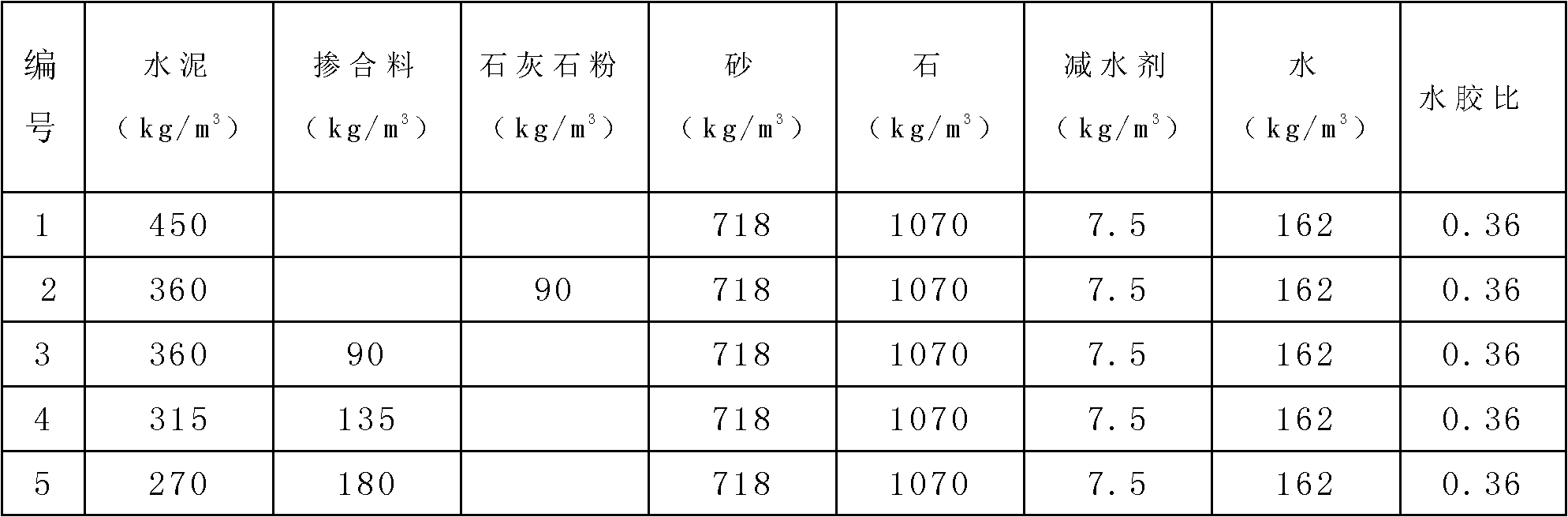

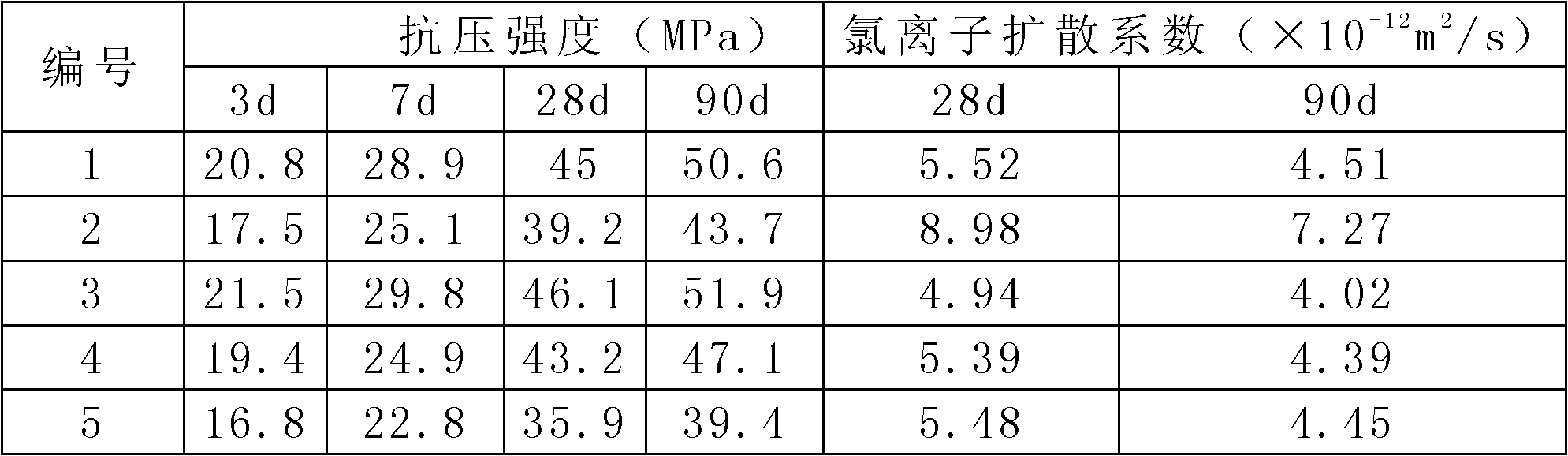

[0021] Use this mineral admixture to prepare concrete, and the mix ratio and properties are shown in Table 1 and Table 2.

[0022] The raw materials used are: 42.5 ordinary Portland cement is used for cement, river sand with a fineness modulus of 2.6, gravel is continuously graded crushed stone of 5-25mm, and...

Embodiment 2

[0028] The Blaine specific surface area is 350m 2 60 parts / kg of limestone powder, Blaine's specific surface area is 400m 2 / kg of slag powder 40 parts, Blaine specific surface area 450m 2 4 parts per kg of calcined gypsum and 0.03 parts of triethanolamine are mechanically stirred, mixed evenly to make a modified limestone powder-based mineral admixture, wherein: slag powder is the molten slag discharged when smelting pig iron, and the 7-day activity index is not less than 75%, dry powder with an activity index of not less than 95% in 28 days, calcined gypsum is calcined by gypsum at a temperature of 780, CaSO 4 Dry powder with a content greater than 85%.

Embodiment 3

[0030] The Blaine specific surface area is 350m 2 70 parts / kg of limestone powder, Blaine's specific surface area is 400m 2 / kg of slag powder 30 parts, Blaine specific surface area 450m 2 5 parts per kg of calcined gypsum and 0.03 parts of triethanolamine are mechanically stirred, and mixed evenly to make a modified limestone powder-based mineral admixture, wherein: slag powder is the molten slag discharged when smelting pig iron, and the activity index in 7 days is not less than 75%, 28-day activity index of not less than 95% dry powder, calcined gypsum is calcined by gypsum at 750°C, CaSO 4 Dry powder with a content greater than 85%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Blaine specific surface area | aaaaa | aaaaa |

| Blaine specific surface area | aaaaa | aaaaa |

| Blaine specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com