A high-early-strength polycarboxylate water-reducer for subway segment concrete

A polycarboxylate-based, high-early-strength technology, which is applied in the field of high-early-strength polycarboxylate-based water reducers for subway segment concrete, can solve the problem of failing to consider the high thixotropy of subway segment concrete and the failure of concrete The influence of thixotropy, the slow development of concrete strength and other problems can achieve the effect of accelerating the reaction speed of silicon-calcium hydration, strengthening the steric hindrance effect and shortening the demoulding time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

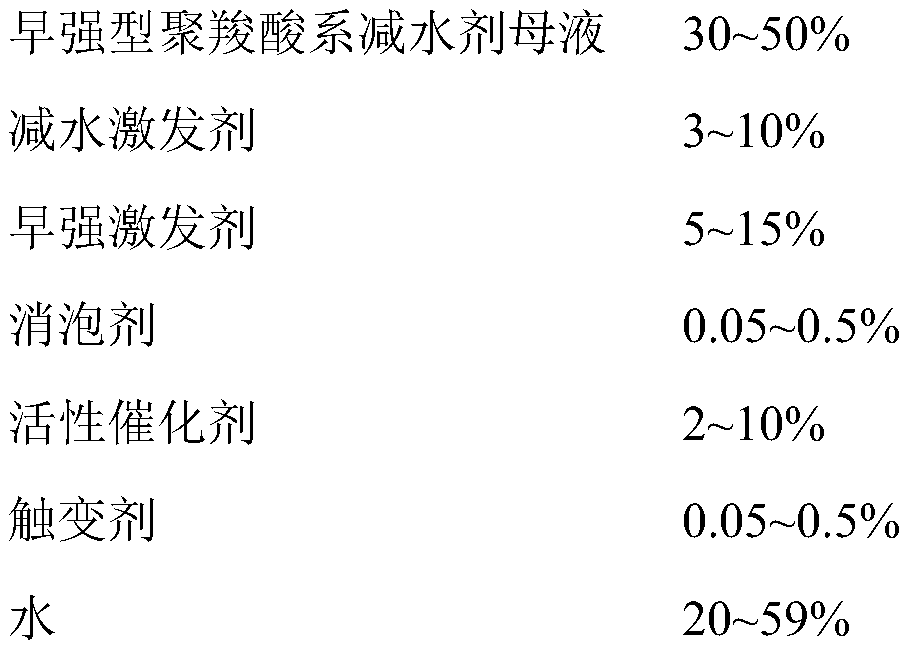

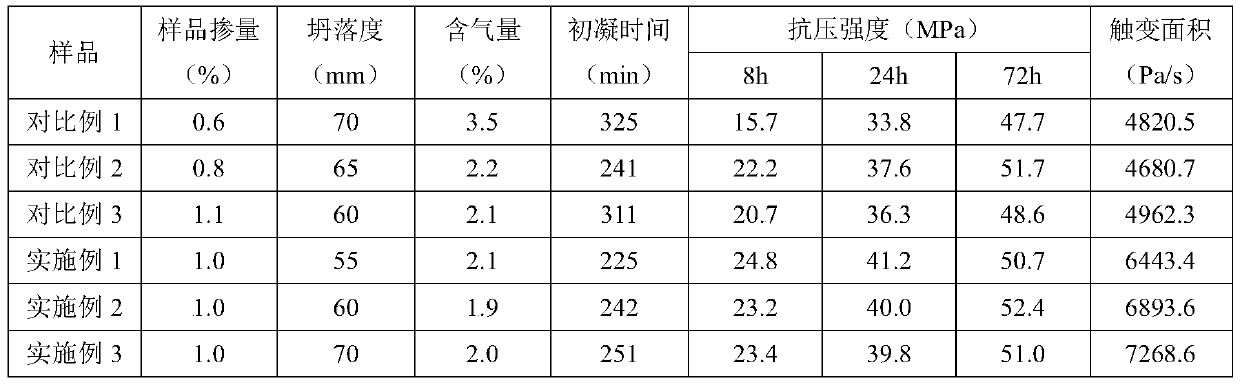

[0020] A high-early-strength polycarboxylate water-reducer for subway segment concrete

[0021] The mass percentage of each component is: 35% mother liquor of early-strength polycarboxylate water reducer, 4% diethylene glycol, 4% polyether amine, 3% organic alcohol amine, 12% sodium thiocyanate, polyether Antifoaming agent 0.1%, active catalyst 2%, thixotropic agent 0.05%, water 39.85%.

Embodiment 2

[0023] A high-early-strength polycarboxylate water-reducer for subway segment concrete

[0024] The mass percentage of each component is: 40% mother liquor of early-strength polycarboxylate water reducer, 2.5% diethylene glycol, 2.5% polyether amine, 3% organic alcohol amine, 7% sodium thiocyanate, polyether Antifoaming agent 0.2%, active catalyst 5%, thixotropic agent 0.1%, water 39.7%.

Embodiment 3

[0026] A high-early-strength polycarboxylate water-reducer for subway segment concrete

[0027] The mass percent of each component is: 45% mother liquor of early-strength polycarboxylate-based water reducer, 1.5% diethylene glycol, 1.5% polyether amine, 2% organic alcohol amine, 3% sodium thiocyanate, polyether Antifoaming agent 0.3%, active catalyst 8%, thixotropic agent 0.2%, water 38.5%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com