Light renewable resource acoustic board and preparation method thereof

A technology of renewable resources and sound-absorbing panels, which is applied in sound insulation, building components, building structures, etc., can solve the problems of poor decorative effect, short service life and poor fireproof performance of sound-absorbing panels, and achieve faster hydration reaction speed and service life Long, good water resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

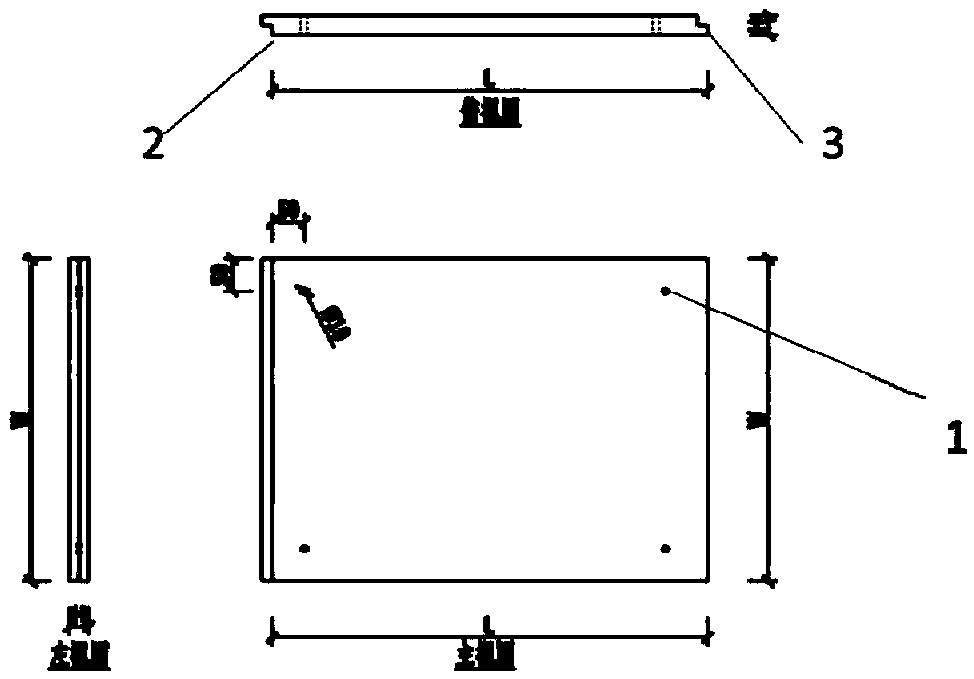

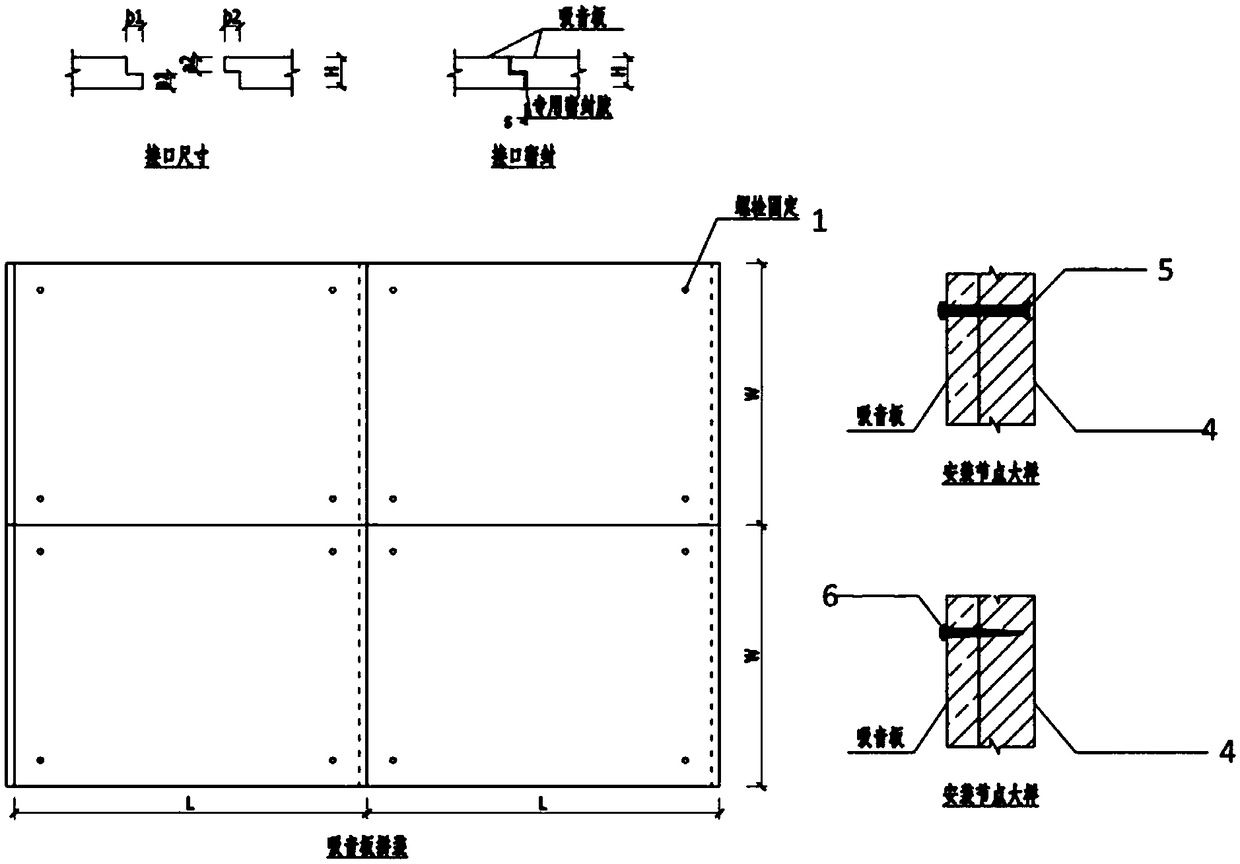

[0077] A light-weight renewable resource sound-absorbing board, the sound-absorbing board is made of solid waste with an aggregate particle size not greater than 20 mm, a compressive strength greater than 10 MPa, a sound absorption coefficient greater than 0.65, good fire resistance, good water resistance, and good durability The sound-absorbing material is prefabricated with reinforcement.

[0078] The light-weight renewable resource sound-absorbing board includes the following raw materials in parts by weight:

[0079] 150 aggregates of discarded ceramic flakes with a particle size of 5-10 mm;

[0080] 100 parts of clay ceramsite with a particle size of 5-10mm;

[0081] 400 parts of waste red brick or lime-sand brick aggregate with a particle size of 10-20 mm;

[0082] 20 parts of rubber particles with a particle size of 0.06-0.315mm;

[0083] 150 parts of cement whose strength is not less than 32.5MPa;

[0084] 50 parts of admixtures with an average particle size of 5-3...

Embodiment 2

[0100] Except that the formula of light-weight renewable resource sound-absorbing board is different, other conditions are the same as embodiment 1.

[0101] A light-weight renewable resource sound-absorbing panel, comprising the following raw materials in parts by weight:

[0102] 300 parts of waste ceramic sheet aggregate with a particle size of 5-10mm;

[0103] 230 parts of clay ceramsite with a particle size of 5-10 mm;

[0104] 650 parts of waste red brick or lime-sand brick aggregate with a particle size of 10-20mm;

[0105] 50 parts of rubber particles with a particle size of 0.06-0.315 mm;

[0106] 300 parts of cement whose strength is not less than 32.5MPa;

[0107] 150 parts of admixtures with an average particle size of 5-30 μm;

[0108] 5 parts of wood fiber with a length of 10-20mm;

[0109] 10 parts of mineralizer;

[0110] 30 parts of pigment powder;

[0111] 7 parts of high-performance admixture;

[0112] The water-cement ratio is 0.5.

Embodiment 3

[0114] Except that the formula of light-weight renewable resource sound-absorbing board is different, other conditions are the same as embodiment 1.

[0115] A light-weight renewable resource sound-absorbing panel, comprising the following raw materials in parts by weight:

[0116] 190 parts of waste ceramic flake aggregate with a particle size of 5-10mm;

[0117] 130 parts of clay ceramsite with a particle size of 5-10 mm;

[0118] 460 parts of waste red brick or lime-sand brick aggregate with a particle size of 10-20mm;

[0119] 30 parts of rubber particles with a particle size of 0.06-0.315mm;

[0120] 180 parts of cement whose strength is not less than 32.5MPa;

[0121] 75 parts of admixtures with an average particle size of 5-30 μm

[0122] 2 parts of wood fiber with a length of 10-20mm;

[0123] 3 parts of mineralizer;

[0124] 15 parts of pigment powder;

[0125] 4 parts of high-performance admixture;

[0126] The water-cement ratio is 0.3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Sound absorption coefficient | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com