Patents

Literature

50results about How to "Improve moth resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for producing high-density recombined wood

InactiveCN102172940AHigh static bending strengthHigh surface hardnessWood compressionVeneer manufactureHigh densityEngineering

The invention relates to a method for producing high-density recombined wood, which is used for manufacturing plates and recombined module timber by the following steps of planning, processing by high-temperature steam, drying, dipping glue, draining glue, drying after draining glue, tidying or weaving, balancing for nourishing, pressing to shape, solidifying at a high temperature and the like. The density of the high-density recombined wood can reach 0.7-1.2kg / cm<3>; the high-density recombined wood has the characteristics of peculiar texture, fine grain, excellent performance, small possibility of cracking and deforming and the like, does not need to prevent insects, prevent mildew, prevent corrosion, prevent from cracking and the like, and can be directly used for the fields of floor, furniture, building and the like. The method disclosed by the invention has simple working procedures, and abandoned secondarily secondary small fuel wood and secondary small wood are utilized to produce plates and module wood, thereby changing waste materials into things of value, and greatly saving forest resource. The wood is an ideal log substitute.

Owner:浙江仕强竹业有限公司

Method for preparing decorative material by utilizing modified plant straws

InactiveCN104530735AImproves strength and hardnessImprove stabilityReed/straw treatmentCorn starchMagnesium

The invention relates to a method for preparing a decorative material by utilizing modified plant straws. The preparation method comprises the following steps: with 100 parts of plant straws by weight as a cardinal number, weighing 20 parts of waste plastic particles, 3 parts of bamboo powder, 0.5 part of curcumin, 2 parts of calcined shell, 1 part of metal magnesium powder, 5 parts of calcined kaolin, 1 part of a fire retardant, 2 parts of linear polyethylene, 0.8 part of a silane coupling agent, 1 part of hydroxypropyl methylcellulose, 0.8 part of modified corn starch, 1 part of soybean oil, 0.5 part of cyclohexanone and 2 parts of nanometer silicon dioxide; airing the plant straws, smashing, drying straw powder, sending the straw powder to a reaction kettle to react, taking out the straw powder, cooling, and sending the straw powder to a refrigerating device to obtain modified straw powder; mixing the modified straw powder and other materials, pouring the mixture to a grinding machine and grinding for 2 hours; and carrying out hot melting extrusion to mold. The decorative material has high fire resistance, corrosion resistance, moisture resistance, steeping resistance, worm-eaten resistance, dimensional stability and the like.

Owner:王旭

Modification technology capable of improving strength and tenacity of wood

InactiveCN104802262AHigh strengthImprove toughnessWood treatment detailsWood impregnation detailsVacuum pressureThermal treatment

The invention relates to the technical field of wood modification, in particular to a modification technology capable of improving strength and tenacity of wood. The modification technology comprises the following steps: A. preparation of impregnation liquid which is prepared from the following raw materials in parts by weight: 10-30 parts of melamine modified urea resin, 6-10 parts of dextrin, 1-5 parts of a nanometer modifying agent, 1-3 parts of a flexibilizer, 1-5 parts of auxiliaries and 60-100 parts of water, weighing the raw materials according to the weight proportion and uniformly mixing to obtain the impregnation liquid; B. impregnating: performing vacuum-pressure impregnation treatment on the wood, and enabling the wood to adsorb the impregnation liquid; C. drying: drying the impregnated wood; D. thermal treatment: conducting thermal treatment on the dried wood under a vacuum state. The modification technology disclosed by the invention can obviously improve the strength and the tenacity of the wood, is simple in steps, convenient to operate and control, stable in quality, high in production efficiency and capable of realizing large-scale industrial production.

Owner:HUNAN DONGLIANG WOOD IND

Method for preparing greening fence based on waste plastics and straw

The invention relates to a method for preparing a greening fence based on waste plastics and straw. The method comprises the following steps: 1) naturally airing the collected plant straws, then cutting and crushing to prepare straw powder for later use; 2) collecting the waste plastics and related products, washing, drying and then performing crushing treatment to perform plastic particles for later use; 3) drying the straw powder till the water content is within 5% and further performing modification treatment on the straw powder; 4) performing steam sterilization on the plastic particles, further drying, mixing with the modified straw powder in the step 3), uniformly mixing and then sending into a granulating machine for granulating to obtain mixed particles for later use; 5) burdening the mixed particles; and 6) putting the materials in the step 5) into a hot runner co-extrusion mold for hot melting and extrusion, well mixing the materials, and then introducing into a hot runner for being jointed with a whole molding production line for molding. The prepared product has great strength, hardness, acid-alkali resistance, corrosion resistance and no deformation and is easy to recover, and is an environment-friendly material.

Owner:ANHUI HONGDA PLASTICS TECH

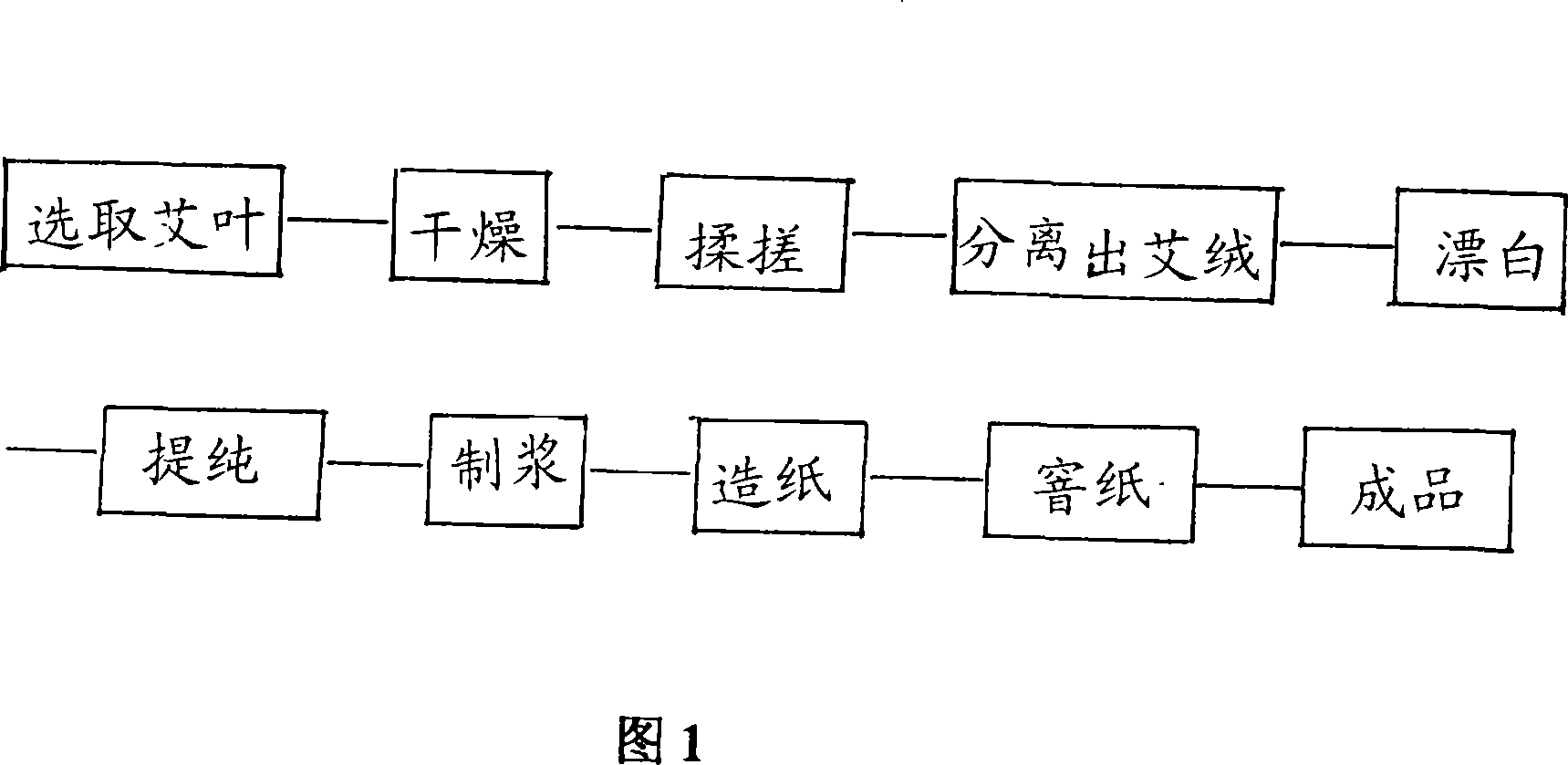

Process for manufacturing argyi leaf functional paper

InactiveCN101135123AImprove separation rateHigh purityVegetable material additionNon-woody plant/crop pulpPapermaking

The present invention relates to papermaking technology, and is especially functional moxa leaf paper making process. The present invention features that the functional moxa leaf paper is made with moxa leaf as material and through one improved papermaking process including the steps of sorting moxa leaf, drying, kneading, separating, bleaching, purifying, making pulp, making paper and scenting paper. The functional moxa leaf paper is applied for painting and calligraphy, as wall paper, in decoration, etc, and has the features of long preservation period, environment friendship and functional function.

Owner:河南绿莹艾草制药有限公司

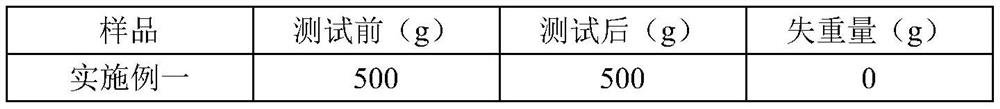

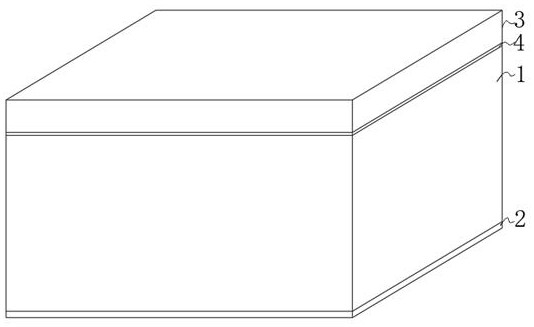

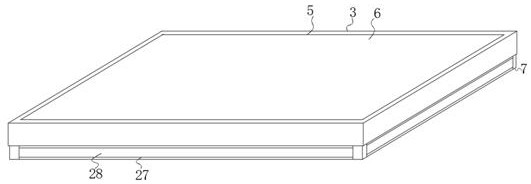

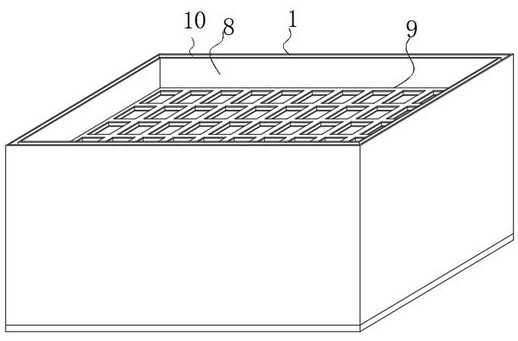

Method for manufacturing moth-proof and low-formaldehyde wardrobe plate

ActiveCN105108841AResidue reductionImprove water resistanceLaminationLamination apparatusAdhesiveMoisture resistance

The invention relates to a building material for home furnishing, in particular to a method for manufacturing a moth-proof and low-formaldehyde wardrobe plate. The method for manufacturing the moth-proof and low-formaldehyde wardrobe plate is characterized by comprising the steps of lathing a plank into pieces, conducting drying, trimming edges, applying adhesive, conducting prepressing, conducting hot-pressing, sanding cut edges, conducting moth proofing treatment, attaching abrasion resistant paper, conducting decoration veneering and sealing the edges. According to the method for manufacturing the wardrobe plate, the formaldehyde residual amount is small, an aluminum alloy frame is inlaid at the periphery of the wardrobe plate, moisture in the air can be effectively prevented from permeating the plate, the moisture resistance and water resistance of the wardrobe plate are improved, the wardrobe plate obtained through the manufacturing method has good moth prevention performance, mold prevention performance, moisture protection performance and abrasion resistant performance, the formaldehyde residual amount is small, damage to a human body is reduced, the obtained wardrobe plate is stable in quality, the dimension stability is good, the plate is not prone to being cracked, damaged or deformed, and the service life is long.

Owner:广州市艾依格家居制品有限公司

Lightweight wood-plastic composite fiberboard and preparation method thereof

The invention discloses a lightweight wood-plastic composite fiberboard and a preparation method thereof. The lightweight wood-plastic composite fiberboard is composed of hot-ground wooden fiber, high-density polyethylene, a foaming agent and other additives. The prepared composite fiberboard has wooden fiber content of 60 to 70%, average density of 800 to 900 kg / m<3>, an average pore size of 50 [mu]m and porosity of 20 to 30%. The preparation method comprises the following steps: subjecting the wooden fiber to alkaline activation and isocyanate grafting; and then subjecting the modified wooden fiber, polyethylene, the foaming agent and other auxiliary agents to high-speed mixing, granulation, mould pressing, foaming and rapid cooling. The lightweight wood-plastic composite fiberboard has same advantages as a fiberboard and a wood-plastic composite and has the advantages of good dimensional stability, high strength-to-weight ratio, good shock resistance, anticorrosion performance, pest damage resistance, sound insulation performance, heat insulation performance, etc. The lightweight wood-plastic composite fiberboard has a wide application scope and is applicable to fields like decoration, buildings, floors, municipal projects, packaging and automotive interior decorative parts.

Owner:BEIJING FORESTRY UNIVERSITY

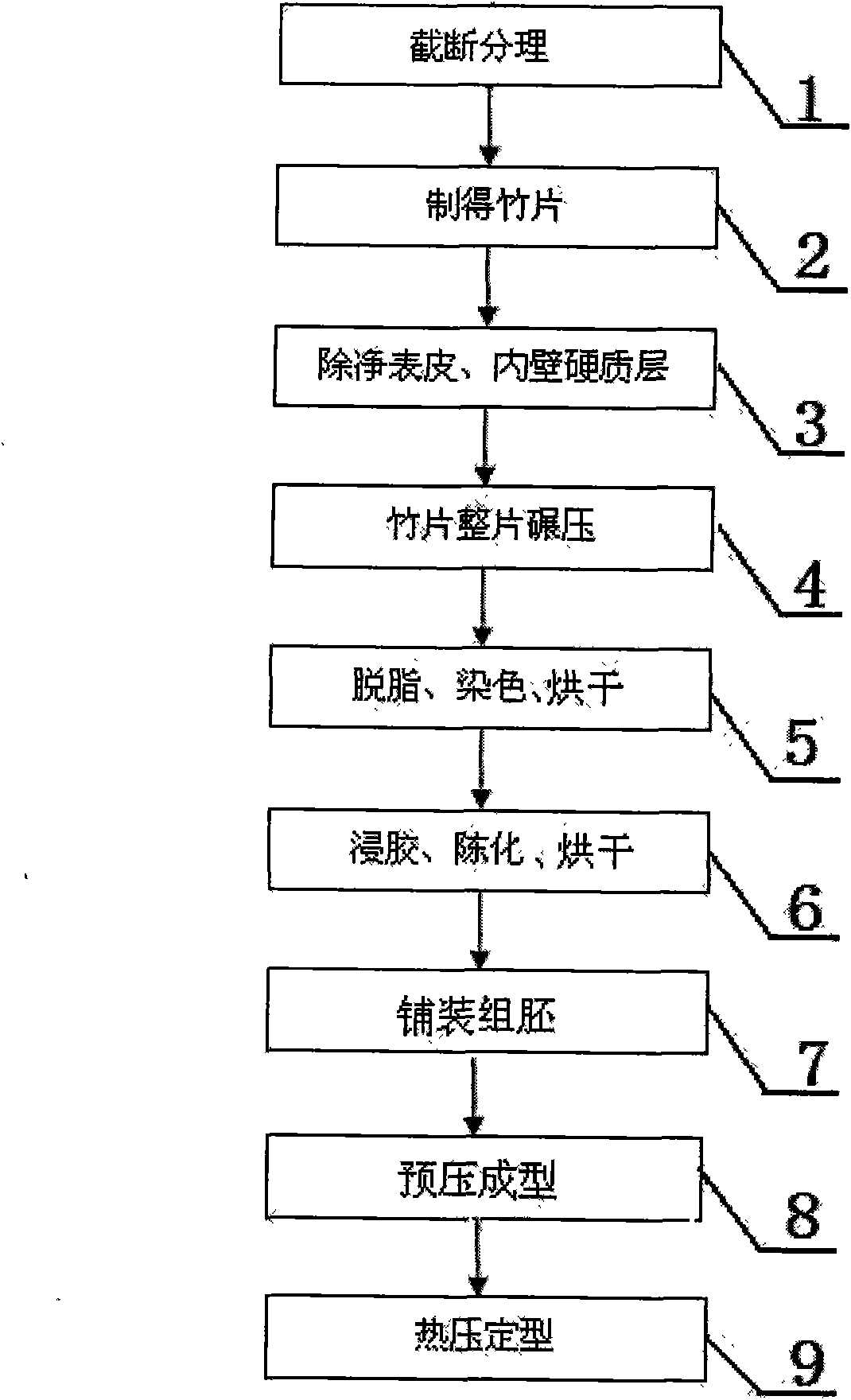

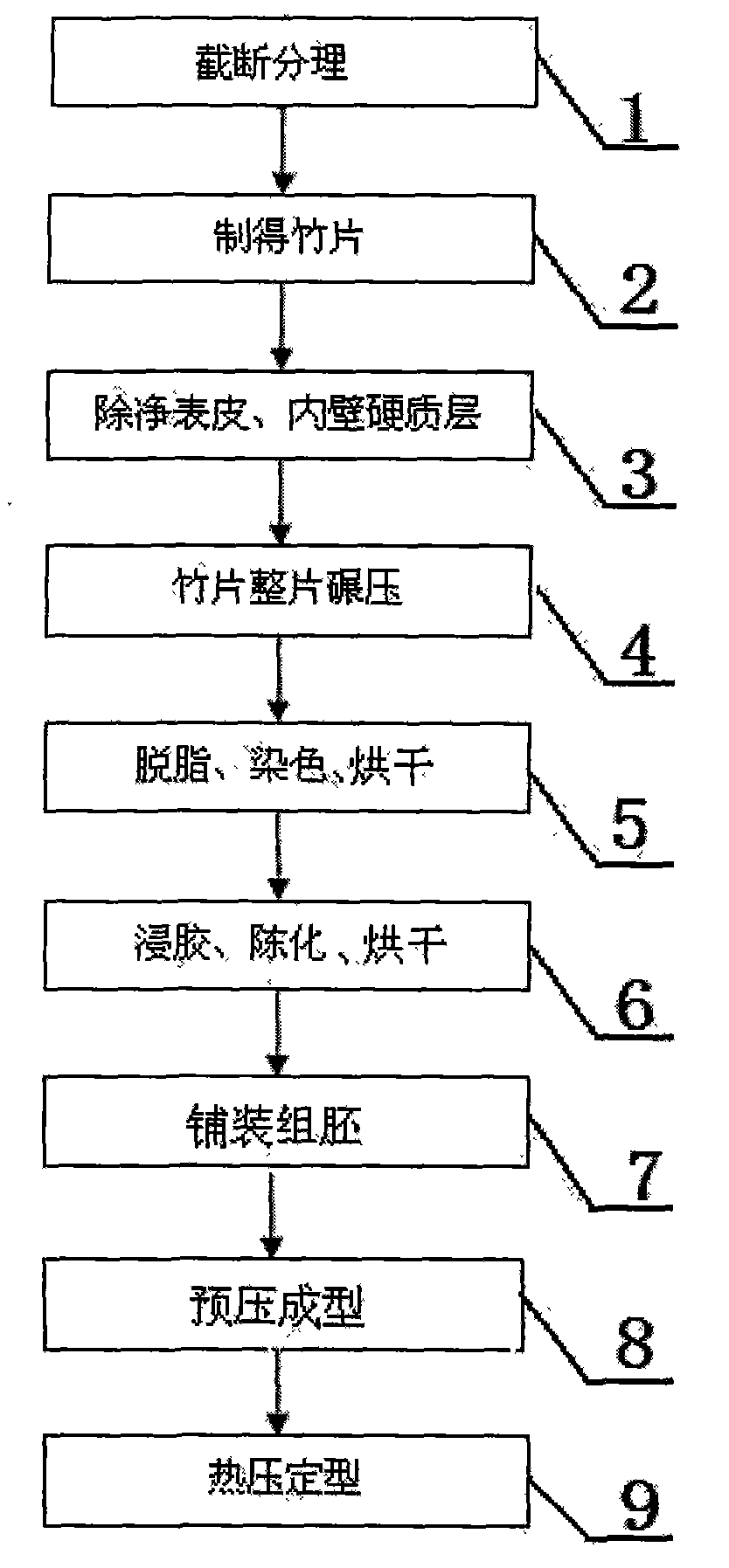

Process for manufacturing full-bamboo embossed pattern plate

InactiveCN101890748AImprove deep processingIncrease profitDecorative surface effectsWood treatment detailsHigh intensityManufacturing engineering

The invention discloses a process for manufacturing a full-bamboo embossed pattern plate. In the process, modified bamboo fibers, bamboo filaments and bamboo strips are paved and arranged in a bundle shape on a pattern template with a customized pattern and are made into a wide high-strength high-density embossed pattern-face embryonic plate through high temperature and high pressure. The process for manufacturing the full-bamboo embossed pattern plate can increase specifications and varieties of materials and save the materials and labor.

Owner:葛会龙 +1

Preparation method for functional finishing of wool fabric through plant pectin

InactiveCN104532570AImprove performanceImprove moth resistanceAnimal fibresDistilled waterEngineering

The invention discloses a preparation method for functional finishing of wool fabric through plant pectin. The method comprises the following steps that 1, a pectin finishing solution is prepared, the plant pectin extracted through the method is fully dried at the normal temperature, the dried plant pectin is squeezed into pectin powder, pectin of a certain weight is obtained through weighing and put into a measuring cup, then distilled water of a certain volume is obtained through weighing and poured into the measuring cup containing the pectin, the mass fraction of the pectin in the prepared finishing solution ranges from 3% to 6%, the bath ratio of the finishing solution is 1:40-50, and finally the pectin and the distilled water are heated in a set thermostat water bath and stirred continuously by a glass bar for 30-40 minutes until the pectin is completely dissolved; 2, the pectin solution is finished, after the pectin is completely dissolved, prepared wool fabric is scoured and then completely soaked into the finishing solution, timing is conducted when the wool fabric is completely padded, the wool fabric is continuously stirred by the glass bar, after about 30-40 minutes, the wool fabric is taken out, washed 2-3 times through clear water and twisted dry, and the wool fabric is placed in a fixed-temperature and fixed-humidity laboratory and naturally dried.

Owner:YANCHENG INST OF IND TECH

Wood enhancement and corrosion prevention modification liquid and preparation method thereof

InactiveCN104802252ASimple processEasy to operate and controlWood treatment detailsWood impregnation detailsPreservativeHardness

The invention relates to the technical field of wood modification, in particular to a wood enhancement and corrosion prevention modification liquid and a preparation method thereof. The wood enhancement and corrosion prevention modification liquid comprises the following raw materials in parts by weight: 10-30 parts of melamine modified urea resin, 4-8 parts of dextrin, 1-5 parts of a nano modifier, 0.5-1.5 parts of a preservative, 1-5 parts of auxiliaries and 60-100 parts of water. According to the wood enhancement and corrosion prevention modification liquid, the intensity and the corrosion resistance of woods can be improved; furthermore, the insect bite, mildewing, water, flame, deformation and cracking prevention performance of the modified woods are greatly improved; the density, the hardness, the anti-bending intensity and the elastic modulus are higher, so that the use performance of the woods can be improved, and the service life of the woods is prolonged. The wood enhancement and corrosion prevention modification liquid has natural properties of heat insulation, temperature adjustment, humidity adjustment and the like, is colorful and bright and is high in physical stripe third dimension; a plate looks transparent and natural.

Owner:HUNAN DONGLIANG WOOD IND

Production process of super-stable solid wood floor

The invention discloses a production process of a super-stable solid wood floor. The production process comprises following steps that a floor blank and wax are jointly put into a heating cavity, theheating cavity is in the closed state, air in the heating cavity is pulled away, the heating cavity is in the vacuum state, the floor blank and the wax in the heating cavity are subjected to temperature rise to 100 to 120 DEG C while air exhaust is carried out, after the floor blank is taken out, the floor blank is subjected to standing to be in the normal temperature state, under the natural state, standing is carried out for 15 to 20 days, the floor blank is subjected to sanding thickness fixing, grooving and surface oil or paint coating in sequence, and the finished floor is obtained. The non-deformability, corrosion resistance, and worm eaten preventing effect of the solid wood floor can be obviously improved, and the service life is prolonged.

Owner:浙江上臣家居科技有限公司

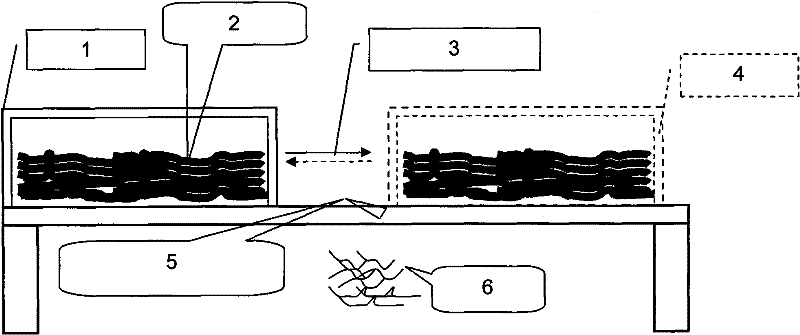

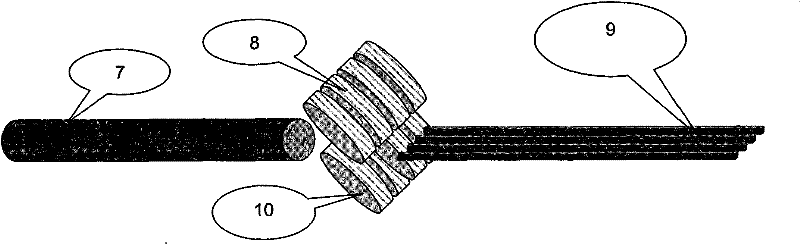

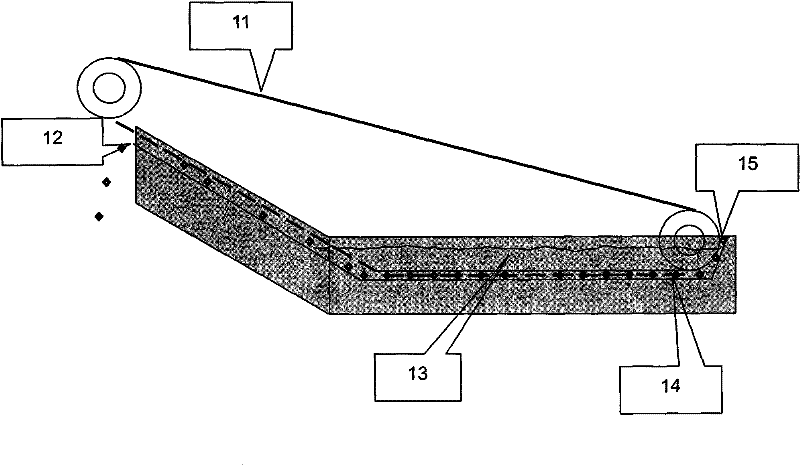

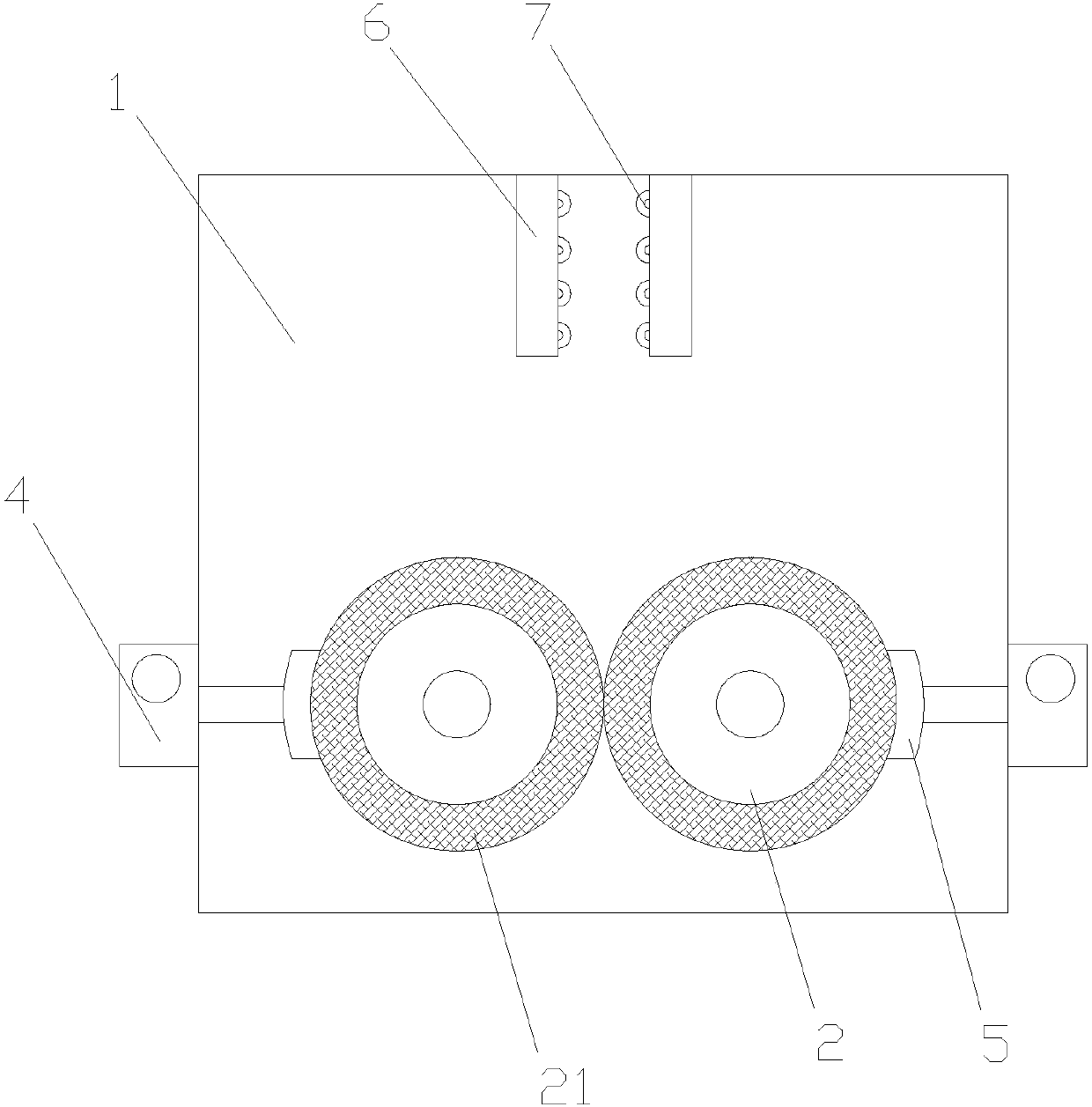

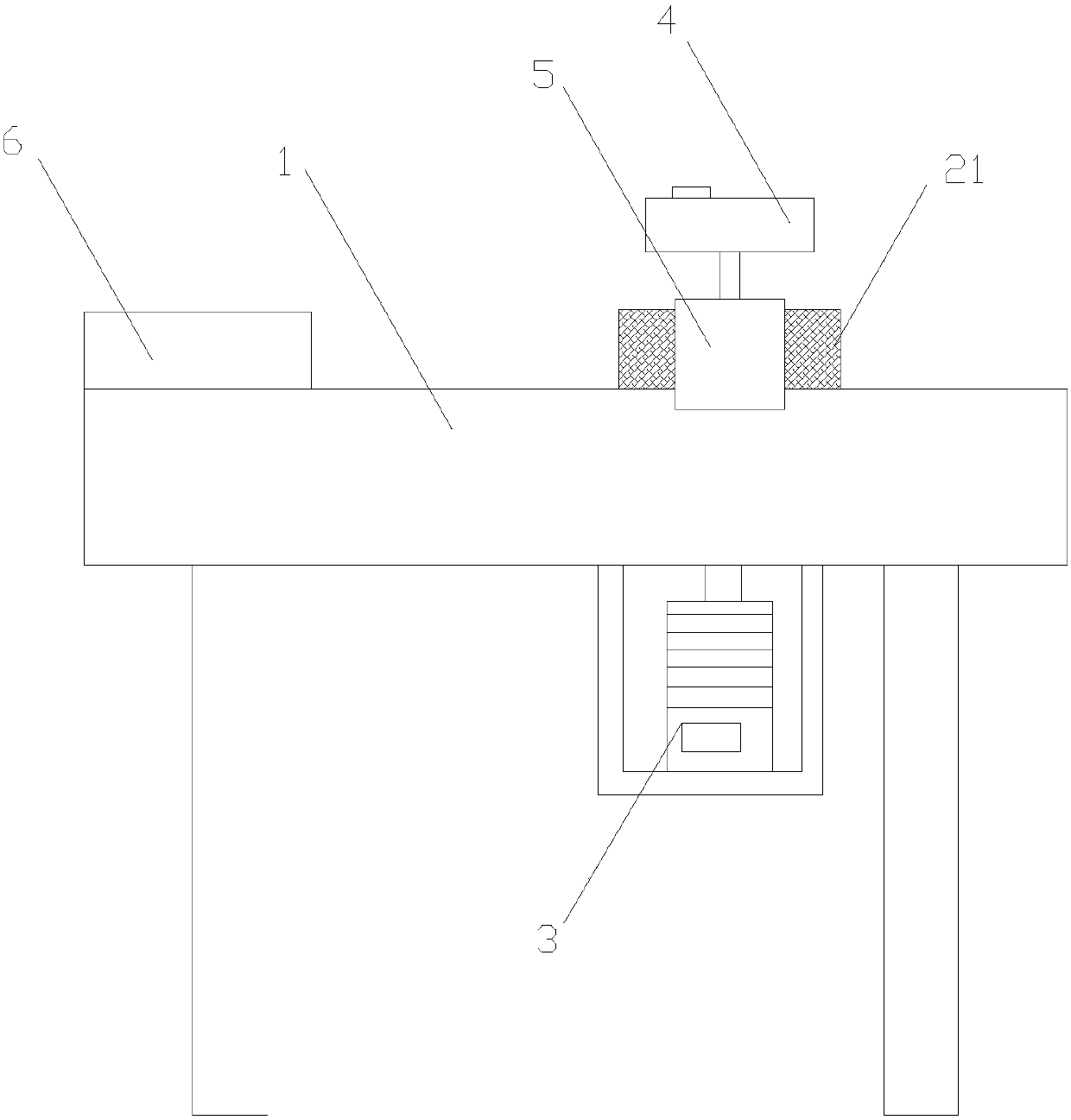

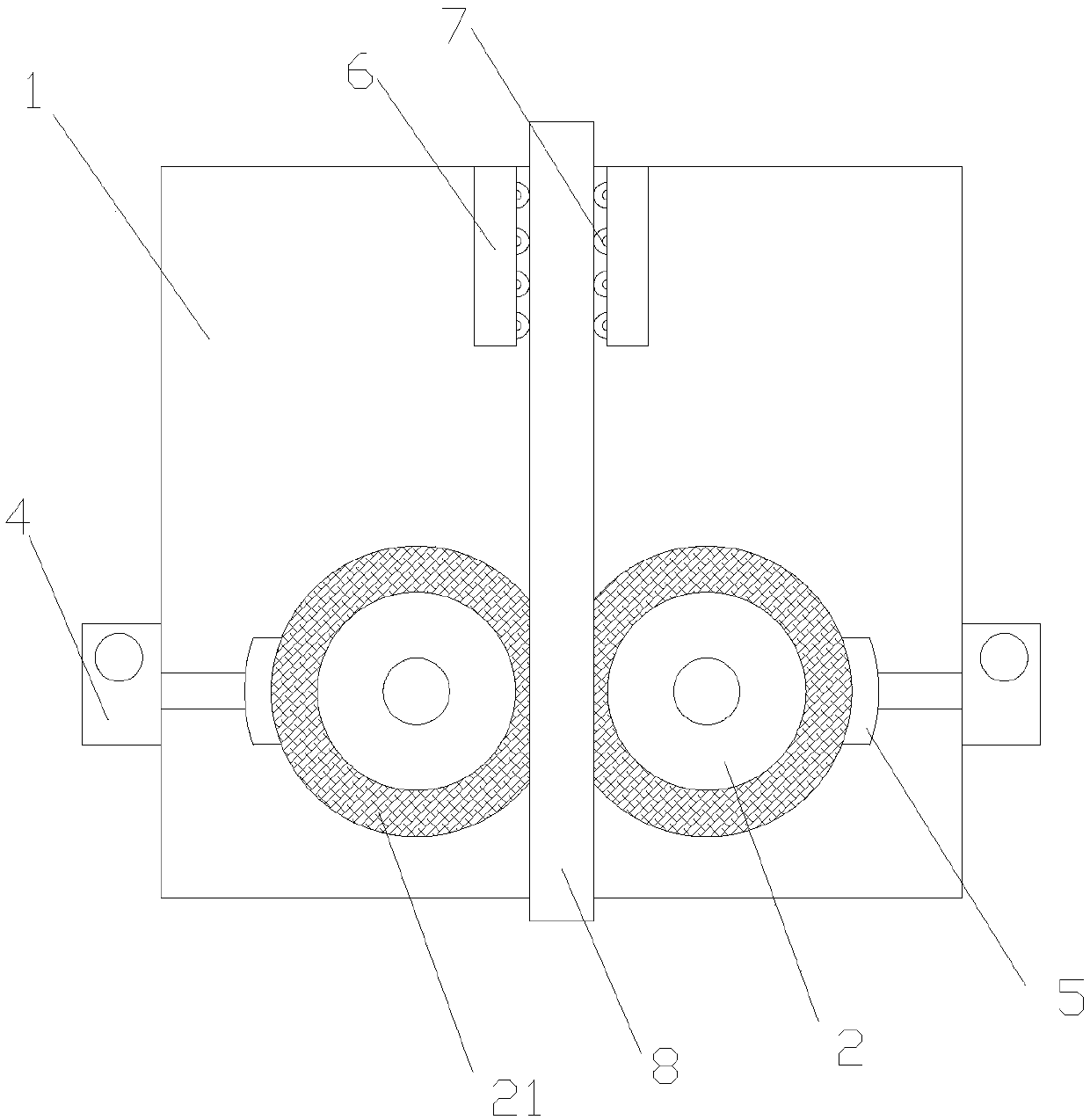

Surface layer coating agent coating device for wicker basket weaving wickers

InactiveCN107553647AQuality assuranceGuaranteed qualityCoating impregnationCoatingsSurface layerDrive motor

The invention discloses a surface layer coating agent coating device for wicker basket weaving wickers, and relates to the field of wicker basket weaving equipment. The surface layer coating agent coating device comprises a conveying table, two conveying wheels, coating sleeves, driving motors, reagent barrels and guiding frames. The conveying wheels are installed in the middle of the conveying table, the coating sleeves are installed outside the conveying wheels, the coating sleeves are of sponge structures, and coating agent injection tubes are installed on the outer sides of the coating sleeves; and the coating agent injection tubes are connected to the reagent barrels through pipelines, the reagent barrels are fixed to the two side edges of the conveying tables, the driving motors areconnected and installed at the bottoms of the conveying wheels, and the guiding frames are further installed at the front end of the conveying table. According to the surface layer coating agent coating device for the wicker basket weaving wickers, the structure is simple, the design is reasonable, using is convenient, conveying of the wickers and coating of a coating agent can be tightly combinedtogether, the process step of independent coating is reduced, and the wicker processing efficiency is effectively improved.

Owner:FUNAN NATURE ARTS & CRAFTS

Coating and damp-proofing method of surface of wood material

InactiveCN102242340BNot easy to adsorbSmall amount of deformationVacuum evaporation coatingWood treatment detailsSurface cleaningPolymer thin films

The present invention is a moisture-proof method for coating the surface of wooden materials. The process steps are as follows: 1. cleaning the surface of the wooden material; 2. placing the wooden material after the surface cleaning treatment in a vacuum coating machine; The waterproof coating material is evaporated into a gaseous state in the evaporation chamber, and then enters the cracking chamber, where it is cracked into active monomers with reactive characteristics; this active monomer is gradually deposited on the surface of the wood material in the deposition chamber to aggregate and crystallize; forming a thickness of 1~5um Highly cross-linked pinhole-free polymer film waterproof membrane layer. Advantages: reduce the deformation of wood materials after moisture absorption, and greatly improve the waterproof and moisture-proof performance of materials. Maintain the unique color, mechanism and performance of the wood itself, improve the moisture-proof, mildew-proof, anti-corrosion, and moth-proof properties of the material, and use wood resources more effectively.

Owner:JIANGSU SHENGFENG CONSTR

Method for manufacturing improved wood board

InactiveCN1600509AImprove corrosion resistanceImprove moth resistanceWood treatment detailsWood impregnation detailsEngineeringWood plank

A method for preparing modified board is featured as utilizing negative pressure technigue to fill epoxy glue into capillary holes of board sufficiently and to distribute the epoxy glue on surface of board uniformly, then solidifying the epoxy glue for obtaining modified board. The prepared board not only has good performance of anticorrosion and antibugbite but also has excellent performance of impact-proof and wearproof.

Owner:王会明 +1

Antiseptic wood used for wood doors and windows

InactiveCN107199612ANo pollutionHigh liquid permeabilityWood treatment detailsPressure impregnationOctanoic AcidsHazardous substance

The invention belongs to the technical field of wood processing, and particularly relates to antiseptic wood used for wood doors and windows. The antiseptic wood is characterized in that wood is firstly subjected to fire-retarding and crack-proofing treatment and further subjected to preservative treatment; an impregnation liquid used for fire-retarding and crack-proofing treatment comprises the following components: boric acid, sodium molybdate, diammonium phosphate, a composite surfactant and water; and a preservative solution comprises the following components: N-methylol resin, a rosin emulsion, octanoic acid, polyethylene glycol, methanesiliconic acid sodium salt, disodium octoborate tetrahydrate, linseed oil and ethyl alcohol. According to the antiseptic wood used for wood doors and windows, after wood is subjected to vacuum and high pressure impregnation treatment in a treatment tank, the liquor permeability of wood is good, the preservation property, flame retardance, corrosion resistance and moth damage resistance of wood are improved, the produced antiseptic wood does not contain any toxic and harmful substance, the antiseptic wood is safe and health for the human body and quite applicable to wood doors and windows.

Owner:HEFEI YIZHI DOORS & WINDOWS CO LTD

Anti-moth paint mortar and preparing method thereof

InactiveCN106318208AStrong adhesionHigh hardnessAntifouling/underwater paintsNatural resin coatingsStalactiteLacquer

The invention relates to an anti-moth paint mortar and preparing method thereof. The raw material of anti-moth paint mortar comprises refined raw lacquer, quartz powder, quicklime powder, wood powder, stalactite powder, insect repellent, adhesive. The materials is prepared from, by weight, 30-40 parts of refined raw lacquer, 25-35 parts of quartz powder, 20-25 parts of quicklime powder, 15-22 parts of wood powder, 5-12 parts of stalactite powder, 10-15 parts of insect repellent and 8-12 parts of adhesive. The preparing steps are as follows: (1) preparing the mixed powder; (2) preparing the insect repellent; (3) mixing. The anti-moth paint mortar adopts fungal enzyme for refining processing of raw lacquer, and can effectively adjust the rheology of the raw lacquer. The produced paint mortar has strong adhesion and high hardness, with corrosion-resistant, wear-resistant, and anti-moth function. It is easy to be smeared on the wood embryo to improve the hardness and strength of wood embryo and to fill the holes as well as the gaps on the board. The anti-moth agent is made by the extraction of active ingredients from Chinese medicine, and enhances the pest control effect on the board.

Owner:哈尔滨漆艺之星科技发展有限公司

Green decorative board containing waste plastic and straw

The invention relates to a green decorative board containing waste plastic and straw. The invention is characterized in that the decorative board is prepared from the following components in parts by weight: 70-90 parts of plant straw powder, 5-20 parts of waste plastic particle, 1-3 parts of polyester rubber powder, 0.5-1 part of silicon carbide, 1-2 parts of kieselguhr, 0.5-1 part of chlorinated paraffin wax, 2-5 parts of polypropylene fiber, 2-8 parts of carbon fiber, 0.2-0.6 part of boron fiber, 0.5-1 part of flame retardant, 0.5-2 parts of tea fiber, 0.5-2 parts of tobacco cellulose, 1-2 parts of linear polyethylene, 0.5-0.8 part of silane coupling agent, 0.5-1 part of hydroxypropyl methyl cellulose, 0.6-0.8 part of modified corn starch, 0.5-1 part of antioxidant and 0.5-2 parts of stabilizing agent. The decorative material has the advantages of high flame retardancy, corrosion resistance, moisture resistance, immersion prevention, vermin resistance, high dimensional stability and the like.

Owner:王旭

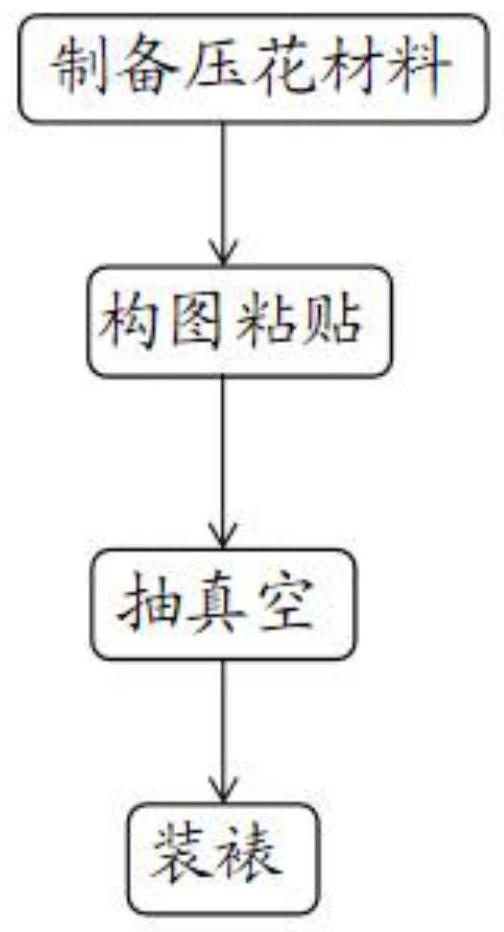

Manufacturing method of pressed flower paintings

InactiveCN113479009AEasy to storePrevent discolorationDecorative surface effectsSpecial ornamental structuresMechanical engineeringDecyl glucoside

The invention discloses a manufacturing method of pressed flower paintings. The manufacturing method comprises four steps: preparing a flower pressing material, pasting for composition, vacuumizing and mounting. The preparation process of the flower pressing material specifically comprises four steps: material preparation, color retention or color development, pressing and drying. In order to ensure that the flower pressing material has good storability and aesthetic feeling, a decyl glucoside cleaning solution can be adopted to clean a plant raw material, and a color retention agent or a color developer is adopted to carry out pigment stabilization or color development treatment on the plant raw material; in order to create the effects of moisture prevention, oxidation and fading prevention or worm damage prevention and the like, the collection value and the ornamental value of the pressed flower painting can be improved through treatment such as electric heating ironing or vacuumizing. Therefore, by means of the manufacturing method of the pressed flower paintings, the technical problems that the existing pressed flower painting is poor in preservation effect, and the ornamental value is prone to being damaged are solved.

Owner:海南满家福健康科技有限公司

Bamboo cotton fiber art printing canvas and art work printed by same

InactiveCN108621670AEasy to displayEasy to collectDecorative surface effectsPretreatment apparatusFiberYarn

The invention discloses a bamboo cotton fiber art printing canvas. The bamboo cotton fiber art printing canvas is prepared according to the following steps: S1, rolling natural bamboo into a thread-line state, then removing fat, sugar and lignin by cooking, and extracting bamboo fibers; S2, electrostatically spraying an antibacterial solution onto the surfaces of bamboo fibers, and then carrying out microwave treatment, wherein the microwave frequency is 100-250MHz, and the microwave treatment time is 2-5min; S3, blending the bamboo fibers and cotton fibers into bamboo-cotton blended yarns inproportion; S4, weaving the bamboo-cotton blended yarn into fabric; S5, cutting the fabric into the canvas of the required size and shape according to the requirements of painting and calligraphy works for the picture. The invention also discloses an art work printed on the bamboo cotton fiber art print canvas. The bamboo cotton fiber art print canvas which is provided by the invention and is prepared by blending the bamboo fibers and the cotton fibers, is scratch-resistant and flat, has good air permeability and heat dissipation property, has a flat, stiff and smooth surface, and is smooth and fine; the calligraphy and painting work printed on the canvas has better lingering charm and artistic expressive force.

Owner:ZIBO VOCATIONAL INST

Heat-resistant and waterproof epoxy asphalt pavement material and preparation method thereof

InactiveCN108892959AIncrease heat resistance and waterproof performanceImprove aging resistanceBuilding insulationsEpoxyWear resistant

The invention discloses a heat-resistant and waterproof epoxy asphalt pavement material. The heat-resistant and waterproof epoxy asphalt pavement material is composed of raw materials including, by weight part, 50 parts of petroleum asphalt, 12-18 parts of polyvinylidene fluoride rubber, 10-15 parts of epoxy resin, 5-9 parts of tetrafluoroethylene-ethylene-ethyl acetate copolymer, 1-3 parts of adipic acid, 3-7 parts of polysebacic polyanhydride, 4-7 parts of hydroxyethyl methylperfluorocaprate, 1-4 parts of a promoter and 10-14 parts of a filler, The heat-resistant and waterproof epoxy asphaltpavement material improves the internal structure microscopically by optimizing special asphalt formulation; the polyvinyllidene fluoride rubber, the epoxy resin and the tetrafluoroethylene-ethylene-ethyl acetate copolymer can enhance the heat-resistant and waterproof performance and the tenacity of mixed asphalt materials; added polylactide filaments can improve the aging-resistant, wear-resistant and corrosion-resistant performances of the heat-resistant and waterproof epoxy asphalt pavement material; boron nitride, zinc oxide and niobium oxide are reasonably proportioned to maximize the heat-resistant and waterproof performances of the heat-resistant and waterproof epoxy asphalt pavement material.

Owner:JIANGSU ZENGGUANG COMPOSITE MATERIAL TECH

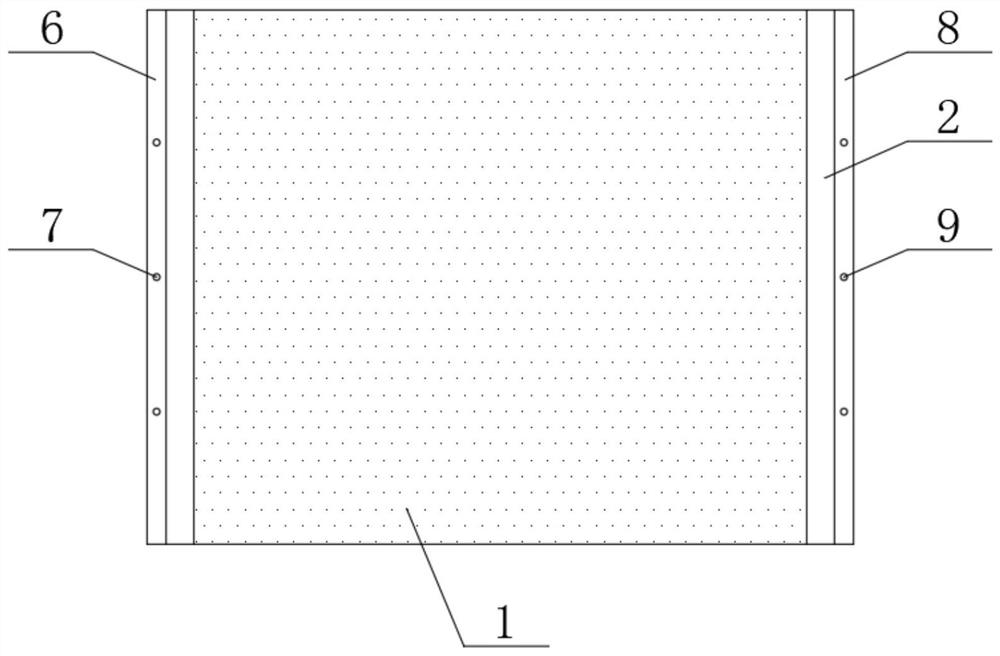

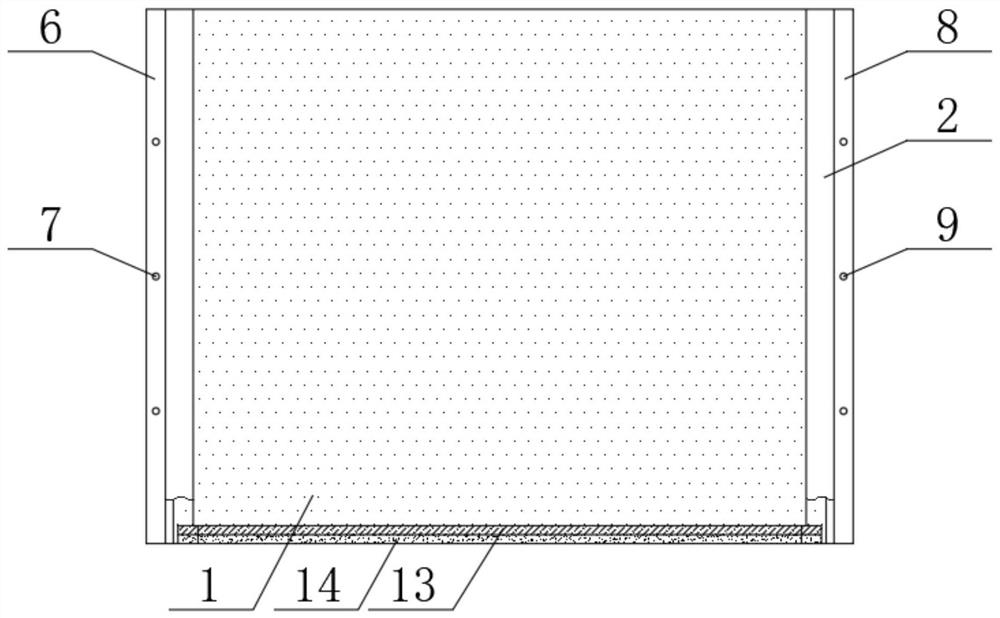

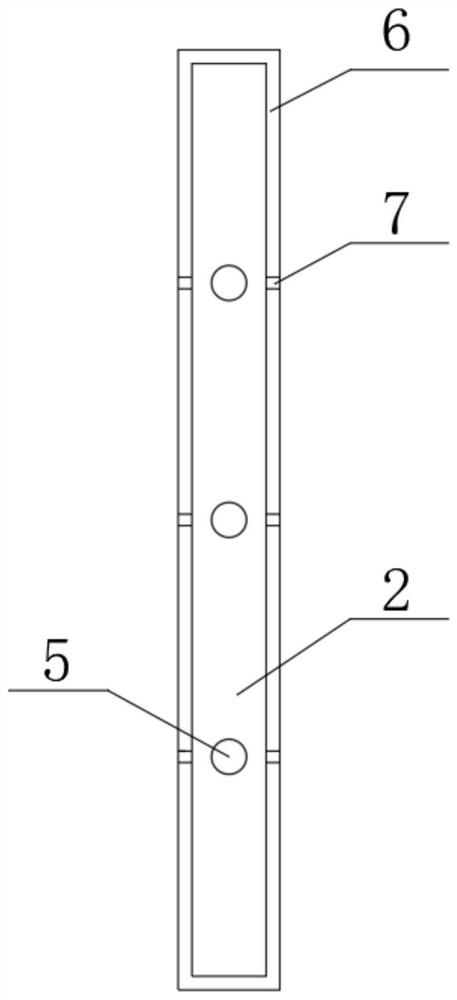

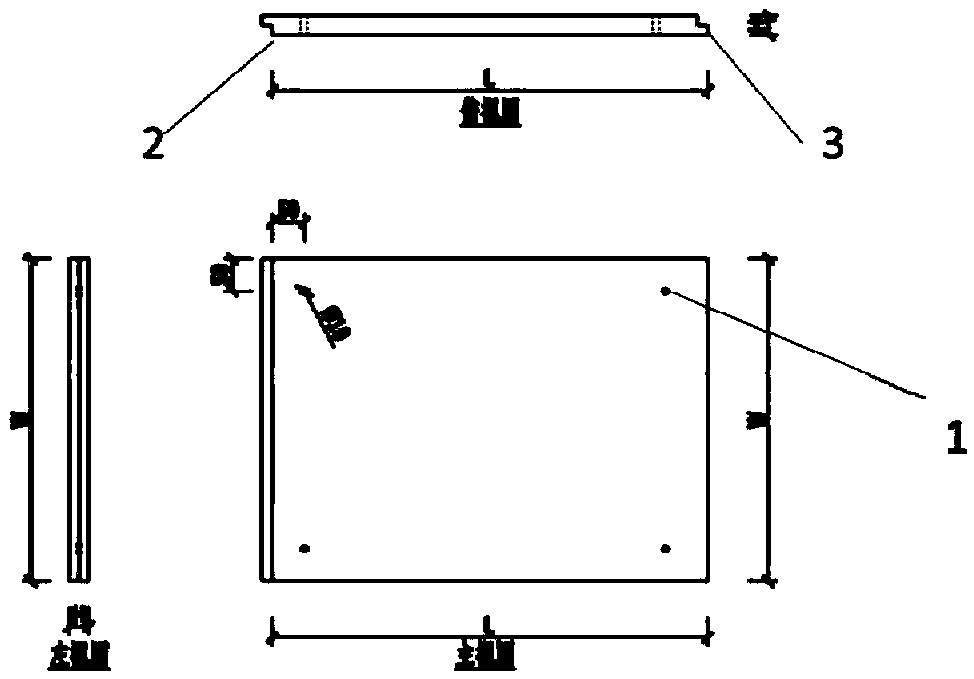

Assembly type connecting structure of light partition board

PendingCN112144705ARealize disassemblyIntegrity guaranteedConstruction materialWallsStructural engineeringMechanical engineering

The invention belongs to the technical field of indoor decoration, and discloses an assembly type connecting structure of a light partition board. The assembly type connecting structure comprises a partition board body, movable frames are movably connected to the two sides of the partition board body, clamping grooves are formed in the tops and the bottoms of the two sides of the partition board body, and the number of the movable frames is two. According to the assembly type connecting structure, by arranging the movable frames, clamping shafts and bolts, when decoration personnel need to disassemble the whole partition board body, the bolts can be screwed out of the interiors of the two sides of the partition board body, and the movable frames can drive clamping shafts to be separated from the two sides of the partition board body by pulling positioning frames and embedded blocks, so that the partition board body can be disassembled conveniently, violent disassembly of the partitionboard body is avoided, the integrity of the whole partition board body is guaranteed, the partition board body can be recycled by decoration personnel conveniently, the operation is simple and convenient, and the practicability of the partition board is improved.

Owner:GOLD MANTIS FINE DECORATION TECH SUZHOU CO LTD

Moth-resistant PP (Polypropylene) foaming board with paradichlorobenzene and preparation method thereof

The invention discloses a moth-resistant PP (Polypropylene) foaming board with paradichlorobenzene and a preparation method thereof. The moth-resistant PP foaming board is prepared from the following raw materials in parts by weight: 88-104 parts of polypropylene resin, 5-10 parts of phenoxyethanol, 7-12 parts of carnauba wax, 14-22 parts of epoxy rice bran oleic acid butyl ester, 16-24 parts of light calcium powder, 4-8 parts of permethrin, 10-15 parts of eucalyptus essential oil, 25-40 parts of sulfur-fixing ash residue, 1-3 parts of azodicarbonamide, 19-36 parts of bauxite tailing, 2-4 parts of lead cyanurate, 13-27 parts of alumina-chrome slag, 15-20 parts of paradichlorobenzene, 14-22 parts of aluminium oxide, 3-6 parts of sodium bicarbonate and 18-34 parts of calcined flint clay tailing. Due to the added materials such as the phenoxyethanol, the permethrin, the eucalyptus essential oil and the aluminium oxide, the moth resistance of the material can be obviously improved. The moth-resistant PP foaming board disclosed by the invention has the advantages of good heat insulation property, good sound-proof effect, good moth-resistant effect, excellent ageing resistance and long service life and the like.

Owner:郭云鹏

Waterproof, fireproof, and insect-proof plant fiber and moulding technology thereof

The invention relates to a waterproof, fireproof, and insect-proof plant fiber and a moulding technology thereof, and belongs to the technical field of construction filling materials. The plant fibercomprises following components in parts by weight: 50 to 60 parts of wheat straws, 10 to 20 parts of peanut shell powder, 5 to 20 parts of a glutinous rice-starch binder, 20 to 22 parts of calcium hydroxide, 3 to 10 parts of paraffin waterproof powder, and 1 to 5 parts of fireproof fibers. Wheat straws and peanut shell powder are taken as the basic materials and are subjected to an antiseptic treatment; the glutinous rice-starch binder and paraffin waterproof powder are compounded so as to firmly bind the wheat straws, peanut shell powder, and other filling materials together; a water repellent layer is formed on the surface of the plant fiber, thus the surface of the plant fiber will not be wetted; moreover, fireproof fibers are added, and the provided plant fiber is resistant to water, fire, and insects.

Owner:安徽润邦环保科技有限公司

Wood protective agent as well as preparation method and application thereof

ActiveCN108943252AImprove performanceHuman and animal safetyWood treatment detailsPressure impregnationHardnessRosin

The invention relates to a wood protective agent as well as a preparation method and application thereof. The wood protective agent comprises the following components, by weight, 10-30 parts of phenolic aldehyde-rosin composite modified resin, 1-2 parts of an emulsion, 1-3 parts of a reinforcing penetrating agent, 3-10 parts of an anti-corrosion and insect-resistant agent, 1-5 parts of an assistant and 55-80 parts of water. The wood treated by the wood protective agent is greatly improved in the aspects of insect resistant, anti-deformation cracking and anti-corrosion performance, moreover, the dimensional stability and the mechanical properties such as hardness and density of the wood are improved, so that the use grade of the wood is remarkably improved, and the service life of the woodis prolonged; and the modified wood has the natural attributes such as temperature adjustment, humidity regulation and the like, color is bright and light, the three-dimensional sense of the physicalstripes is strong, and the color of panel is transparent and natural.

Owner:GUANGDONG ACAD OF FORESTRY

Coating method for improving aging resistance of poplar board

InactiveCN107471357AImprove anti-corrosion performanceImprove moth resistanceRadiation/waves wood treatmentWood treatment detailsSalicylaldehydePolyvinyl chloride

The invention belongs to the technical field of wood treatment, in particular to a coating method for improving aging resistance of a poplar board. The coating method comprises the following specific steps: (1) the processed poplar board is dipped in calcium chloride solution for dipping, and is taken out to dip in ethanol solution; (2) the poplar board is processed by steam, and is taken out for hot pressing and drying; and (3) the poplar board is dipped in paint, and is taken out for microwave drying; and the paint is prepared by the following raw materials: tin powder, salicylaldehyde, polyvinyl chloride resins, petroleum resins, tertiary butanol, algal polysaccharides, acrylic emulsion, tetraethoxysilane and water. The coating method effectively improves corrosion resistance and worm damage resistance of the poplar board, improves the color thickness of the poplar board, greatly improves the surface strength and wear resistance of the poplar board, improves fire resistance and flame retardance of the poplar board, prolongs the service life of the poplar board, and improves the use performance.

Owner:安徽嘉美工艺品有限公司

Content-removed rubber wood powder/high-density polyethylene composite material and preparation method thereof

InactiveCN109354892AImprove corrosion resistanceImprove mildew and corrosion resistanceWood working apparatusPolymer scienceFlexural strength

The invention discloses a content-removed rubber wood powder / high-density polyethylene composite material and a preparation method thereof. The preparation method includes: subjecting rubber wood powder to content-removed pretreatment to obtain content-removed rubber wood powder, well mixing the content-removed rubber wood powder, high-density polyethylene and aid, utilizing a granulator to granulate mixed materials, and shaping to obtain the composite material. The composite material is high in impact-resistant strength and bending strength, small in water-absorbing change rate and good in woody sense, has better mildew-proof and corrosion-resistant performance when compared with wood-plastic composite materials prepared from content-maintained rubber wood powder and can be widely appliedin the field of outdoors, bathrooms, kitchen and balconies.

Owner:SOUTH CHINA AGRI UNIV

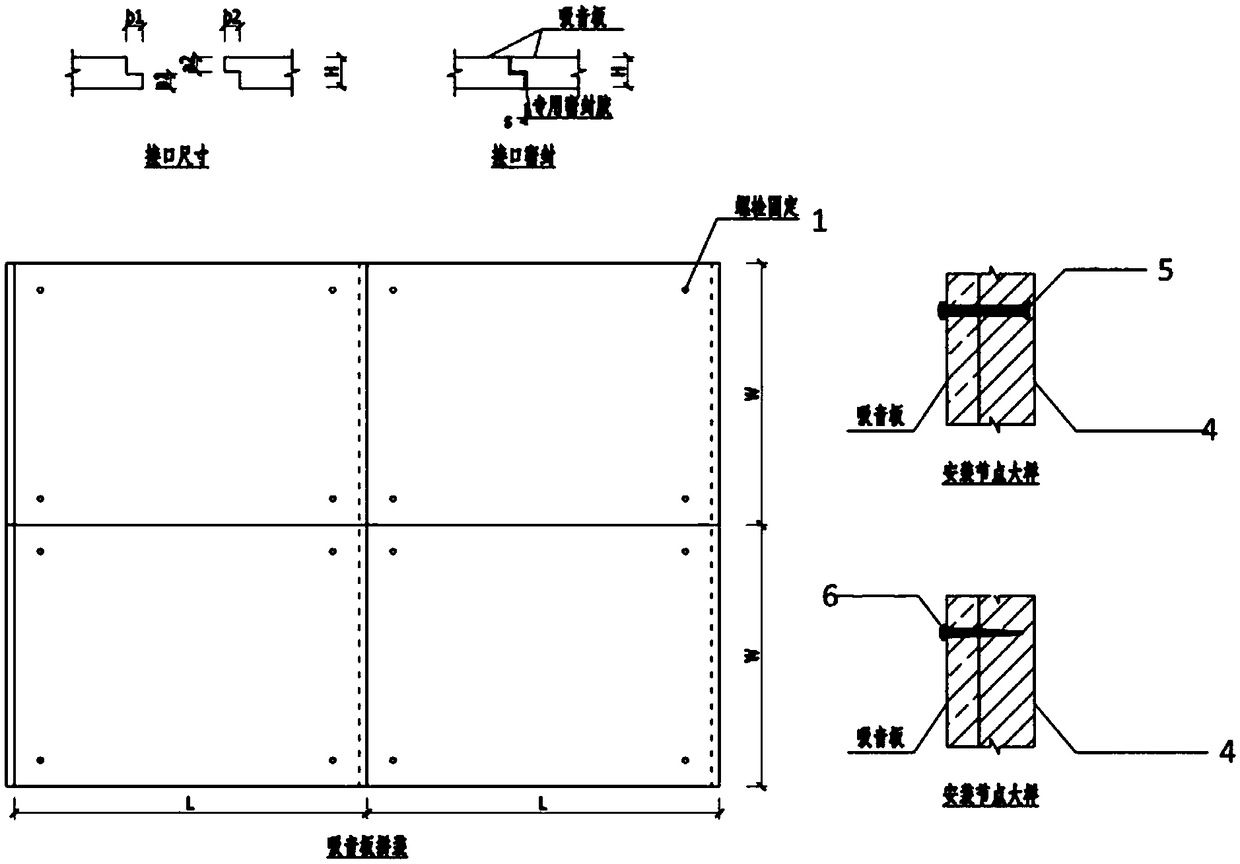

Light renewable resource acoustic board and preparation method thereof

PendingCN109133738AImprove sound absorptionImprove mechanical propertiesSound proofingAcoustic absorptionFire resistance

The invention relates to the technical field of acoustic boards, and discloses a light renewable resource acoustic board which is prefabricated with solid waste acoustic materials in an adding reinforced manner. The aggregate size of the solid waste acoustic materials is not larger than 20mm, the compressive strength of the solid waste acoustic materials is higher than 10MPa, and the acoustic absorption coefficient of the solid waste acoustic materials is larger than 0.65. By an assembled production and construction mode, all prefabricated parts are prefabricated in a factory, transformed to asite and directly assembled, the acoustic board is easy to operate, good in performance and short in construction period, resources are saved, environments are protected, and the requirements of green energy-saving ecological development are met. The problems of low industrial waste use ratio, environmental pollution and the like are solved, the production cost of the acoustic board is reduced, and the mechanical property, the fire resistance and the durability of the acoustic board are improved.

Owner:惠州富盈新材料科技有限公司

Waterproof, fireproof and moth-proof plant fiber and its molding process

The invention relates to a waterproof, fireproof, and moth-proof plant fiber and its molding process, belonging to the technical field of building material fillers. The plant fiber includes the following components in parts by weight: 50-60 parts of wheat straw, 10-20 parts of peanut shell powder, 5~20 parts of glutinous rice-starch binder, 20~22 parts of calcium hydroxide, 3~10 parts of paraffin waterproof powder and 1~5 parts of fireproof fiber; with wheat straw and peanut shell powder as the base material, and for wheat straw, Peanut shell powder is subjected to anti-corrosion treatment, compounded with glutinous rice-starch binder and paraffin waterproof powder, which can firmly bond wheat straw, peanut shell powder and other fillers, and form a hydrophobic layer on the surface of plant fibers to prevent moisture from clouding Wet the surface of the plant fiber, and add the fire-proof fiber to prepare the plant fiber with functions of waterproof, fire-proof and moth-proof.

Owner:安徽润邦环保科技有限公司

Modification method of wood boards

InactiveCN107443520AImprove corrosion resistanceImprove moth resistanceWood treatment detailsPressure impregnationWood plankMaterials science

The invention discloses a modification method of wood boards. The modification method of the wood boards is characterized by fully filling capillary pores of the wood boards with epoxy glue through a negative-pressure filling technique, uniformly distributing the epoxy glue on the surfaces of the wood boards, and then curing the wood boards. The modification method of the wood boards is capable of effectively improving corrosion resistance and resistance to damage caused by insects of the wood; meanwhile, after the epoxy glue is cured, impact resistance and abrasion resistance of the wood boards can be improved; the usage performance of the wood boards is effectively improved.

Owner:广西贵港市长雄干燥科技有限公司

Green packaging box

InactiveCN114873060APlace stableEasy to placePackage recyclingRemovable lids/coversStructural engineeringIndustrial engineering

The invention relates to the technical field of intelligence, in particular to a green packaging box which comprises a box bottom plate, the top of the box bottom plate is fixedly connected with a box body mechanism, the box body mechanism is provided with a box cavity, a protection plate is arranged in the box cavity in a sleeved mode, an embedding opening is formed in the top of the box body mechanism, and an insertion frame is arranged in the embedding opening in a sleeved mode. When the protection plate is placed in the box cavity, the movable triangular sleeve moves towards the interior of the movable cavity under the extrusion action of the edges, so that after the movable triangular sleeve completely enters the movable cavity, the bevel edge at the bottom of the trapezoidal column makes contact with the edges, and under the extrusion action, the bevel edge at the bottom of the trapezoidal column can extrude the movable cavity towards one side; in this way, the second elastic inserting strip and the first elastic inserting strip are recycled, then the top containing plate can quickly enter the box cavity, and when the top containing plate moves to the position of the bearing clamping groove, the second elastic inserting strip and the first elastic inserting strip can be clamped in the bearing clamping groove under the elastic effect.

Owner:谢洋洋

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com