Manufacturing method of pressed flower paintings

A production method and embossing technology, which are applied in the special technology of art painting, special decorative structure, and technology for producing decorative surface effects, etc. Moisture-proof effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

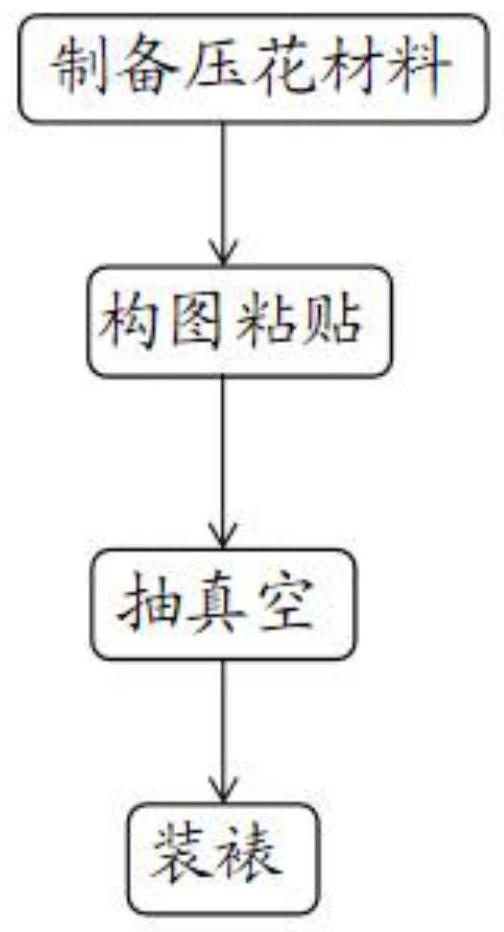

[0029] For ease of understanding, see figure 1 , the present application provides an embodiment of a method for making embossed paintings, comprising the following steps: preparing embossed materials, pattern pasting, vacuuming and mounting;

[0030] Wherein, the step of preparing embossed material comprises:

[0031] S1. Material preparation: pick healthy plant raw materials, clean and dehydrate the plant raw materials, and classify them for later use, wherein the plant raw materials are cleaned with decyl glucoside cleaning solution;

[0032] S2. Color retention or color development: use a color retention agent or a color development agent to perform pigment stabilization or color development treatment on the plant materials classified in step S1, and drain to obtain a color retention plant or a color development plant;

[0033] S3. Squeeze: Squeeze the color-preserving plant or the color-producing plant prepared in step S2 by using the heavy object pressing method, embossi...

Embodiment 2

[0041] As a further improvement on Embodiment 1, the present application provides an embodiment of an embossed painting. Optionally, the plant material is one or more of flowers, leaves, roots, stems and bark. Optionally, in the decyl glucoside cleaning solution, the volume ratio of decyl glucoside to purified water is 1:(3~6). Optionally, the color retaining agent is a copper sulfate solution or a copper acetate solution with a concentration of 25% to 35%. Optionally, the color retaining agent is a mixed solution of phytic acid, sodium tripolyphosphate and sodium hexametaphosphate. Optionally, the chromogenic agent includes tartaric acid or citric acid, and purified water; by volume, tartaric acid or citric acid: purified water=(1~5):(10~15). Optionally, the electric heating temperature of the electric iron is 40-80°C, and the pressing time is 30-80s. Optionally, a water-absorbing material is stacked under the background paper or the art cloth; the water-absorbing material ...

Embodiment 3

[0045] As a further improvement to the above embodiments, the present application provides an embodiment of a method for preparing embossed paintings. Optionally, during the vacuuming process, the glass and the aluminized composite film are sealed with double-sided adhesive or glass adhesive connection; the glass used is UV-resistant glass.

[0046] During the vacuuming process, from top to bottom, there are stacked glass, frame pasted with composition, absorbent paper or board, aluminum-coated composite film (adhesives such as double-sided tape or glass glue can be used to bond the four). connection, the use area of the four can be determined according to the needs), among them, the glass and aluminum-coated composite film that are hermetically connected can be regarded as a "sealed cover", and this "sealed cover" can be regarded as the "sealed cover" of absorbent paper or absorbent board and frame. Leave a small hole on the glass, the vacuum pump and the small hole are con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com